Class I biological safety cabinet is a biological safety isolation equipment used in biological safety laboratories or other laboratories. It is usually used to handle low-risk biological materials. The class 1 bsc is suitable for testing samples without requiring protection. Protect Operator and the Environment.

Class I Biological Safety Cabinet Feature:

Humanized design:

Memory function in case of power-failure

HEPA filter and UV life indicators facilitate a timely replacement plan .

UV lamp for sterilization.

Class 1 bsc is equipped with temperature sensor to show the real temperature during operation.

Waterproof socket provide convenience for small instruments to be used in the operating area.

Perforations at the back wall of the work zone which are designed to eliminate air turbulence and the possibility of dead air corners in the work zone.

Safety Performance:

Front sliding sash interlock with fan and UV lamp

Front sash and side windows are made of UV-resistant tempered glass.

The host and sockets have independent capacitors to prevent current overload.

Class I Biological Safety Cabinet Specification:

| Model | BSC-I-800H | BSC-I-1100H | BSC-I-1300H | BSC-I-1500H | BSC-I-1800H |

| External Size (W×D×H)(mm) | 800×760×1880 | 1100×760×1880 | 1300×760×1880 | 1500×760×1880 | 1800×760×1880 |

| Internal Size (W×D×H)(mm) | 700×630×550 | 1000×630×550 | 1200×630×550 | 1400×630×550 | 1700×630×550 |

| Work Surface Height | 730 mm |

| Max Opening | 350 mm |

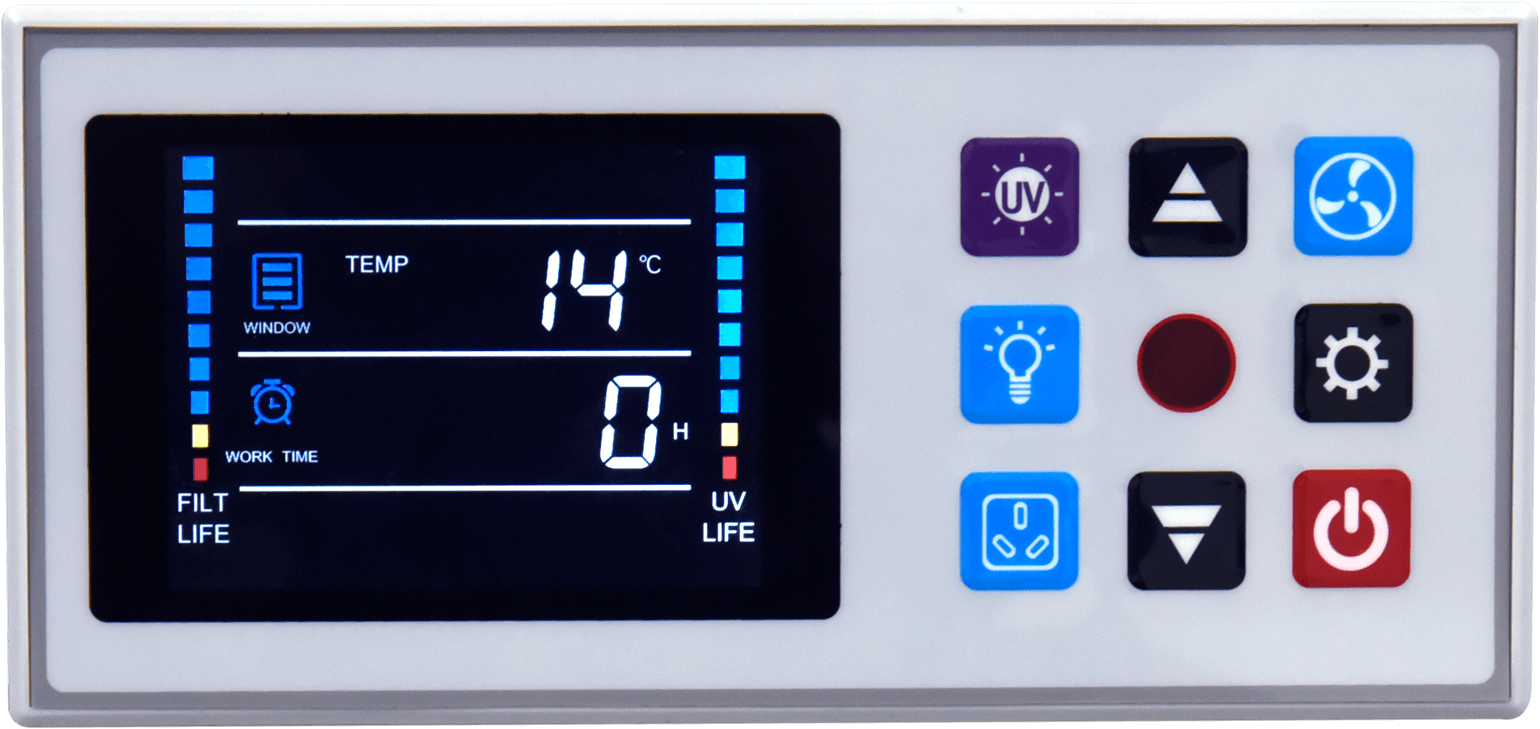

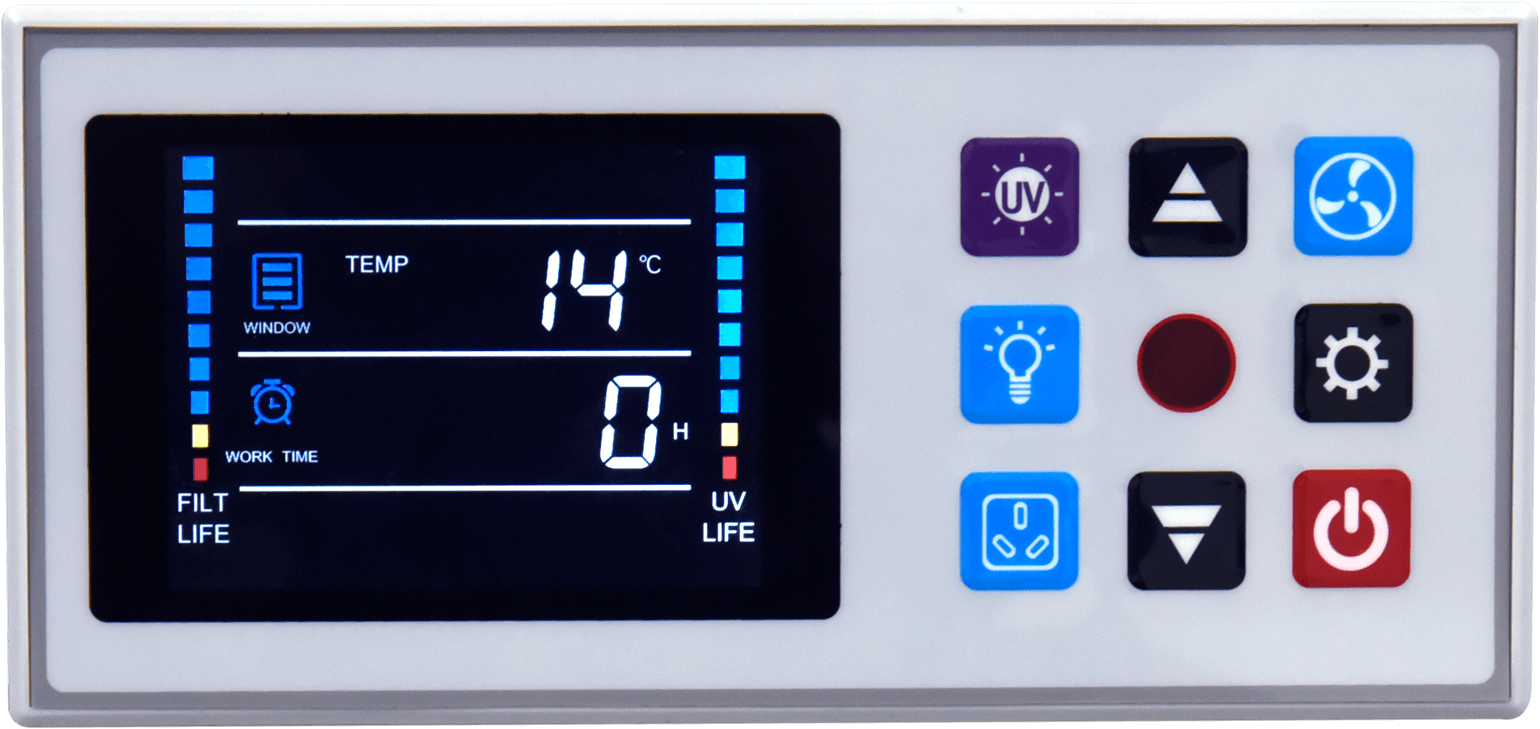

| Control System | Display | 7”LCD touch screen |

| Interlock | Audio and visual alarm (Abnormal airflow velocity, HEPA filter failure, UV lamp failure, Front window at unsafe height) |

| Airflow System | Airflow Velocity | 0.3–0.5m/s, speed adjustable |

| Air Volume | 832 m³/h (490CFM) | 1188 m³/h (699CFM) | 1426 m³/h (839CFM) | 1663 m³/h (979CFM) | 2020 m³/h (1189CFM) |

| Air filtration System | Pre-Filter | 1pcs, Polyester fiber,washable, Filtration efficiency: G3 |

| HEPA Filter | 1 pcs, Efficiency: > 99.995% at particle size of 0.3 μm |

| Cleanliness Grade | ISO Class 5 (formerly Class 100) |

| Partial air circulation | Perforations at the back wall of the work zone and negative pressure channel which are designed to eliminate air turbulence and the possibility of dead air corners in the work zone. |

| Cabinet Construction | Main Body | Electro-Galvanized steel with antimicrobial powder coating |

| Work Surface | 304 Stainless Steel |

| Front Window | Automatic Motorized door, tempered glass, Thickness: 5mm |

| Side Window | 5 mm UV resistant tempered glass |

| Electrical System | UV Lamp | 8 W×1 | 30 W×1 | 40 W×1 |

| Emission of 253.7 nanometers for best sterilization effect |

| LED Lamp | 8 W×1 | 10 W×1 | 20 W×1 |

| Max.Consumption | 350 W | 360 W | 370 W |

| Not include socket loading power consumption |

| Power Supply | AC 220 V±10%, 50/60 HZ; 110 V±10%, 60 Hz |

| Illumination | ≥600 Lux |

| Sound Emission | ≤64 dB(A) |

| Standard Accessory | 1.Air Velocity Sensor×1; 2.Pre-Filter×1; 3.HEPA Filter×1; 4.Waterproof Socket×2; 5.LED Lamp×1; 6.UV Lamp×1; 7.Base Stand. |

| Optional Accessory | 1.Foot Switch; 2.Water Tap; 3.Gas Tap; 4.Differential Pressure Sensor; 5.Manually Adjustable Base Stand; 6.Upgraded LED Lamp; 7.IV Bar with Hooks. |

| G.W.t (kg) | 190 | 220 | 250 | 280 | 330 |

| Shipping Size (W×D×H) (mm) | 950×1060×1630 | 1250×1060×1630 | 1450×1060×1630 | 1650×1060×1630 | 1950×1060×1630 |

| Shipping Volume (m³) | 1.7 | 2.2 | 2.5 | 2.9 | 3.4 |

Class I Biosafety Cabinet Accessory:

LCD Display (Real-time show the Time, Temperature, UV life and Filter life)

UV Lamp (Emission of 253.7 nanometers for most efficient decontamination)

Base stand (Optional)

Waterproof Socket (IP54)

Details of Class I Biosafety Cabinet:

Our class I bsc is packed in sturdy packaging to ensure transport safety. Each biosafety cabinet is double-protected with high-strength foam and wooden crates to avoid collision or damage during transport. We work with reputable logistics companies to ensure our products reach you safely and promptly. We provide a full tracking service during transport so that you can keep track of the status of your order at any time.

WHY SCITEK

18 Months Limited Warranty

ISO, CE and FDA Standards

1-2 Days Handling and 7-30 Days Shipping

FAQ

Difference between Class I and II BSC?

Class I BSC : Protects the operator and the environment but not the sample. Air enters through the front opening and is filtered and discharged to prevent the leakage of hazardous substances.

Class II BSC: This system protects the operator, the sample, and the environment. Air enters through the front opening and is double-filtered. Part of the air is circulated internally, and part is filtered through a HEPA filter and discharged, providing more complete protection.

English

English