| External Size (W×D×H)(mm) | 1200×760×1880 |

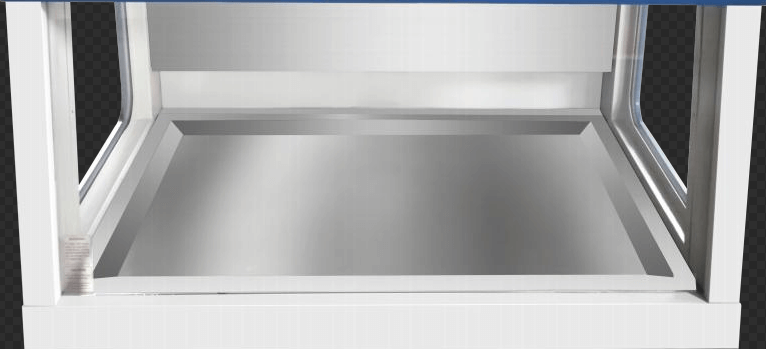

| Internal Size (WxDxH)(mm) | 1100×630×550 |

| Max Opening | 350mm |

| Work Surface Height | 730mm |

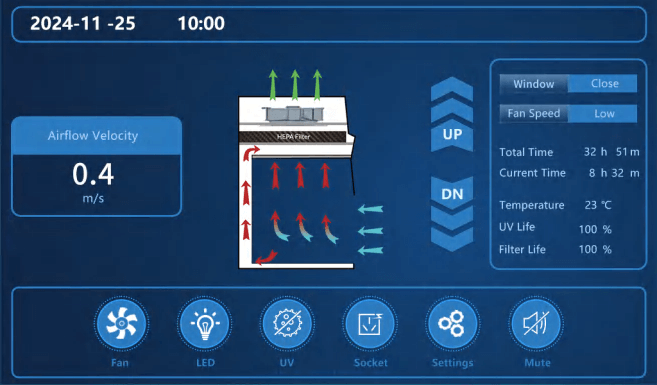

| Control System | Display | 7”LCD touch screen |

| Alarm | Audio and visual alarm (Abnormal airflow velocity, HEPA filter failure, UV lamp failure, Front window at unsafe height) |

| Airflow System | Airflow Velocity | 0.4~0.6m/s, speed adjustable |

| Air Volume | 500m³/h (295CFM) |

| Air filtration System | Pre-Filter | 1pcs, Polyester fiber,washable, Filtration efficiency: G3 |

| HEPA Filter | 1 pcs, Efficiency: > 99.995% at particle size of 0.3μm |

| Cleanliness Grade | ISO Class 5 (formerly Class 100) |

| Partial air circulation | Perforations at the back wall of the work zone and negative pressure channel which are designed to eliminate air turbulence and the possibility of dead air corners in the work zone. |

| Cabinet Construction | Main Body | Electro-Galvanized steel with antimicrobial powder coating |

| Work Surface | 304 Stainless Steel |

| Front Window | Automatic Motorized door, tempered glass, Thickness: 5mm |

| Side window | 5 mm UV resistant tempered glass |

| Electrical System | UV Lamp | 30W×1 (Emission of 253.7 nanometers for best sterilization effect) |

| LED Lamp | 16W×1 |

| Max.Consumption | 650W (Not include socket loading power consumption) |

| Power Supply | 110V±10%, 60Hz |

| Illumination | ≥600Lux |

| Sound Emission | ≤60dB(A) |

| Standard Accessory | 1. Air Velocity Sensor×1 2. Pre-Filter×1; 3. HEPA Filter×1; 4. Waterproof Socket×2; 5. LED Lamp×1; 6. UV Lamp×1; 7. Base Stand; 8. IV Bar with Hooks |

| Optional Accessory | 1. Double HEPA Filter 2. Foot Switch; 3. Water Tap; 4. Gas Tap; 5. Differential Pressure Sensor; 6. Manually Adjustable Base Stand; 7. Upgraded LED Lamp |

| Gross Weight | 250kg |

| Shipping Size (W×D×H)(mm) | 1400×1060×1630 |

| Shipping Volume | 2.4m³ |

English

English