A lab incubator is a common piece of equipment used in laboratories to grow cells, fungi, viruses, bacteria, and other microorganisms. You can set the temperature, humidity, and other environmental conditions, as well as the growth and reproduction of microbial samples, to simulate an optimal growth condition. There are many types of it, such as thermostatic incubators, BOD incubators, lighting incubators, climate incubators, Anaerobic Chambers, CO2 Incubators, Shaking Incubators, etc. With so many types, what are their uses, and how can they be distinguished?

Lab Incubator Principle

The operation of a lab incubator is based on the thermoelectric principle, in which a thermostat maintains a stable temperature by generating a thermal gradient. Under thermal gradient conditions, any conductor produces a voltage, which is known as the thermoelectric effect. When the circuit is energised, the lab incubator is heated to a set temperature (e.g. 40°C). The compatibility and efficient performance of temperature sensors, temperature controllers and temperature contactors are key factors in maintaining temperature.

When the switch is closed, current flows into the system and the energised contactor supplies power to the bulb, which acts as the system's heating element. Through the action of a fan, hot air is distributed throughout the system. When the system temperature reaches the desired level (40°C), the digital temperature controller sends an electrical signal to the contactor, which de-energises and temporarily switches off the heater. In addition, if the temperature falls below the desired level, the contactor recharges and switches the system on to maintain constant temperature conditions.

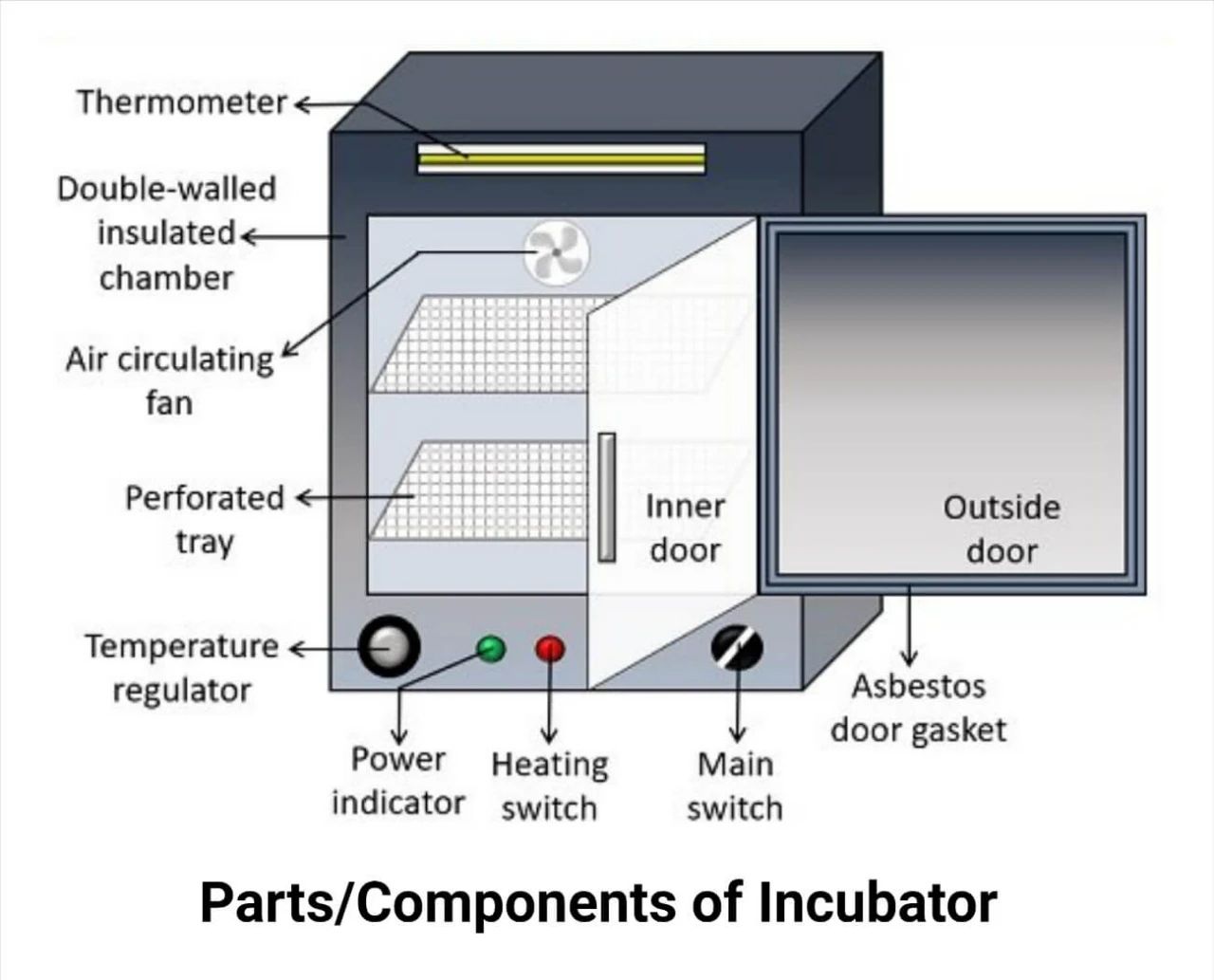

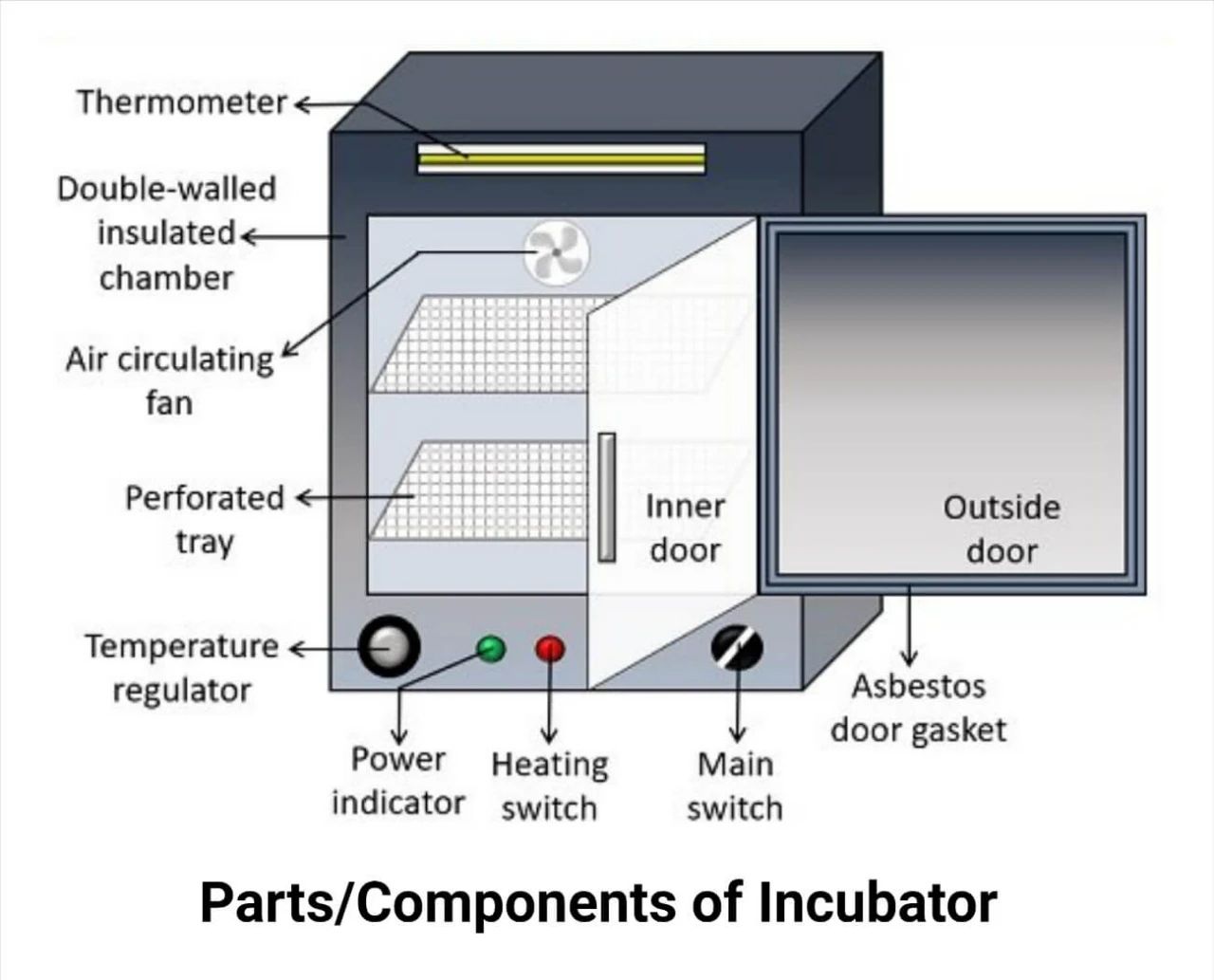

Lab Incubator Components/Parts

Image by Microbe Notes

Cabinet

This is the frame of the whole incubator. Generally, the outer layer is made of corrosion-resistant stainless steel plate, and the inner layer is made of aluminum with good thermal conductivity. The two walls are filled with glass wool to ensure better temperature control. Inside the incubator is an inward protrusion to support the shelves inside the lab incubator.

Door

In order to prevent the entry of outside air and to ensure a stable internal environment, lab incubators are usually well-sealed and have a reliable door. The doors are usually made of transparent glass with an insulating layer, which makes it easy to observe the status inside the incubator. The door is also fitted with an asbestos door gasket to prevent the entry of outside air.

Control Panel

Monitor the temperature, humidity and other parameters inside the incubator, with all the switches and control keys.

Thermostat

The thermostat is used to set the desired temperature of the incubator. Once the desired temperature is reached, the thermostat automatically maintains the lab incubator until the temperature changes again.

Perforated shelf

The shelves hold the culture media and the perforated design allows for a more even temperature flow in the chamber.

HEPA Filter

Some state-of-the-art incubators are also equipped with HEPA filters to minimize possible contamination caused by airflow.

Humidity

CO2 incubators typically have a reservoir underneath the chamber to maintain the relative humidity of the chamber by evaporating water.

Data Logging and Remote Monitoring

Some advanced lab incubators will also feature data logging and remote monitoring so that users can monitor and control experimental conditions even when they are not in the lab.

Lab Incubator Working Principle

1. The basic principle of a lab incubator is to provide micro-organisms with specific conditions to facilitate their growth and development.

2. All lab incubators follow this concept: when organisms are provided with optimum levels of temperature, humidity, oxygen and carbon dioxide, they grow, divide and form more organisms.

3. Inside the lab incubator, a thermostat is responsible for maintaining a stable temperature monitored by an external thermometer.

4. The temperature is kept stable by cycles of heating and non-heating.

5. During the heating cycle, the thermostat heats the incubator; during the non-heating cycle, the heating is stopped and the incubator is cooled by radiating heat to the surroundings.

6. Insulation of the interior from the exterior creates an isolation condition that allows for efficient microbial growth.

7. Other parameters, such as humidity and airflow, are regulated through different mechanisms to simulate conditions similar to the organism's natural environment.

8. Similarly, they can be adjusted to maintain the right concentration of carbon dioxide to balance the pH and humidity required for the organism's growth.

9. Various types of incubators, such as oscillating incubators, are also available to induce cellular aeration and fulfill needs such as solubility studies.

Steps for using the lab incubator:

Before using the lab incubator, ensure there are no leftovers from previous cycles in the incubator and that the chamber is kept neat and free of debris.

1. Keep the lab incubator door closed and open the incubator. The lab incubator is heated to the temperature required for the growth of the particular organism. A thermometer can be used to see if the temperature is reached.

2. Also, if the organism requires a specific CO (2) concentration or a specific humidity level, these parameters should also be set in the lab incubator.

3. Once all parameters have been met, place the petri dish culture upside down on the perforated rack, i.e., with the medium on top.

4. If it is necessary to incubate the petri dish cultures for several days, seal the petri dish with tape or place it in a plastic bag or plastic food container.

5. Lock the door at the end and wait until a certain number of days before opening it again

Lab incubator types:

A laboratory incubator is a common equipment used in scientific laboratories to simulate specific growth conditions to promote the growth and propagation of microorganisms, cells and other biological samples. Depending on the experimental needs, there are various laboratory incubators, including CO2 incubators, constant temperature incubators, constant humidity incubators, and shaker incubators. Each type of lab incubator provides specific control of environmental parameters to meet the requirements of different experiments. Laboratory incubators are important in providing controlled environmental conditions for scientific research and experiments in scientific and medical laboratories. According to the usage, we can classify the incubators into the following types:

Thermostatic Incubator

Thermostatic incubator is also known as waterproof electric incubator, usually divided into electric and waterproof.

1. Electrically heated incubator:

Direct heating with electric heating wire, using air convection, so that the temperature inside the box is uniform.

The way of electric heating, the shell will generally be used for cold plate electrostatic spraying, the inner liner is made of stainless steel, the insulation layer is made of asbestos as the thermal insulation material, and there is a heating pipe at the bottom, which is heated by the heating pipe inside the incubator. Its disadvantage is that the temperature uniformity is relatively poor, the temperature flush is relatively high. It is mainly composed of several parts such as box, heater, blower and temperature controller.

2. Watertight incubator:

The use of electric heating tube heating water heating, so that the temperature inside the box achieves the culture conditions.

The heating tube heats the water in the jacket, using the convection of the water to form four-sided heating, effectively ensuring the uniformity of heating. The water jacket can maintain a constant temperature in case of power failure. It adopts two temperature control modes: microcomputer intelligent temperature controller and bimetal regulator. Temperature control range: room temperature +5 ℃ -60 ℃, can only stabilize the temperature above room temperature without refrigeration.

Both are widely used in medical and health care, pharmaceutical industry, biochemistry, industrial production and, agricultural science and other scientific research departments for bacterial culture, breeding, fermentation and another constant temperature test.

Several important parameters of constant temperature incubator

1. Heating mode: electric heating and waterproof type

2. Volume: small ≤ 50L, large ≥ 400L

3. Temperature range: the general temperature of the incubator is not high, generally between room temperature to one hundred degrees.

4. The thermostatic incubator material: liner material generally has iron and stainless steel two; iron is a little lighter for transport, and stainless steel material is a little more durable.

There are other things, such as more concern about the price, product quality, and scope of use, which also reference the technical indicators.

Thermostatic incubator use and maintenance

1. The box should not be placed in a culture that is too crowded in order to facilitate hot air convection

2. Whether into or out the items should be closed with the door to avoid temperature fluctuations.

3. Electric incubator should be put in the box in a water container to maintain a certain degree of humidity.

4. Watertight incubator should pay attention to the first water and then power, and at the same time, should often check the water level and add water on time.

5. Electrically heated incubator should be used when the top of the wind should be properly rotated to help regulate the temperature inside the box.

Constant Temperature Humidity Incubator

Constant temperature humidity incubator can accurately simulate constant temperature, constant humidity and other complex natural environments, with temperature and humidity control system of a box

Generally used for plant culture, breeding test; bacteria, microbial culture, used for breeding, fermentation, microbial culture, a variety of constant temperature tests, environmental testing, material denaturation tests, and storage of culture media, serum, drugs, and other items.

Constant temperature and humidity box humidification, dehumidification mode:

Humidification method: The steam humidification method is generally used; low-pressure steam is directly injected into the test space humidification. This humidification method, humidity capacity, speed, and humidity control are sensitive, especially in the cooling, and it is easy to achieve forced humidification.

There are two types of dehumidification: mechanical refrigeration dehumidification and dry dehumidification.

1. Mechanical refrigeration dehumidification principle is to cool the air below the dew point temperature to greater than the saturated moisture content of water vapor condensation precipitation to reduce humidity.

2. Dryer dehumidification uses an air pump to pull air out of the test chamber and inject dry air into it. At the same time, the wet air into the dry can be recycled for drying, after drying and sent into the test box, so repeated cycles for dehumidification.

Most integrated test chambers now use mechanical refrigeration dehumidification; the latter dehumidification method is suitable for special occasion requirements, but it is more expensive.

Biochemical Incubator

Biochemical incubator generally has refrigeration and heating two-way thermoregulation system, temperature-controllable function, is a plant, biology, microbiology, genetics, medicine, environmental protection and other scientific research, teaching, research and education departments indispensable laboratory equipment.

1. Biochemical incubator is mainly used for biochemical reaction incubation. Their doors are mainly made of glass, used to incubate the reaction at a specific temperature; the operator can observe the reaction changes outside without destroying the reaction conditions; it can also be used to cultivate bacteria and molds.

2. The workshop is made of stainless steel plate or high-quality cold-rolled steel plate processed and molded, and treated with anti-rust and anti-corrosion.

3. Compressor refrigeration can be adapted to a wide range and maintained at a constant temperature throughout the year.

Mould Incubator

The mould incubator is a high-precision laboratory equipment with the functions of heating, cooling, humidifying and disinfecting, which is widely used for the cultivation of various moulds, tissue cells and microorganisms, as well as for the rearing of insects, small animals and constant temperature test for other purposes.

Mould incubator is suitable for cultivating eukaryotic microorganisms such as moulds, most of moulds are suitable for growth at room temperature (25℃) and need to maintain a certain humidity when cultivated on solid substrate. So it is usually humidified in the mould incubator (if the requirement is not high, you can put a plate or a cup of water, or external humidifier).

Mould incubator than biochemical incubator more than a disinfection function, generally with ultraviolet germicidal lamp, can be used as a biochemical incubator. There are also some mould incubator in the constant temperature, sterilization based on increased humidity control, with humidity control of the mould incubator can also be used as a constant temperature and humidity incubator.

Anaerobic Incubator

Mobile Anaerobic Chamber

Automated Anaerobic Chamber

Anaerobie glove box, i.e. anaerobic incubator, is one of the internationally recognised instruments for the cultivation of anaerobic bacteria.

Generally it is a large, airtight metal box with a transparent panel made of Plexiglas in front of the box. The panel is fitted with two gloves, which can be used to operate inside the box.

Structure

It is divided into four parts: anaerobic chamber, transfer chamber, operation hole of bare hand sleeve, air circuit and circuit control system.

Anaerobic chamber: Mechanical forced convection and positive pressure in the inner chamber to achieve constant temperature, humidity control, deoxidation, biological detoxification of four stable and uniform state, and rapid recovery, operation and cultivation at the same time.

Transfer chamber: Compact cylinder design enables easy transfer of samples by one person with one hand.

Bare hand cuff operation hole: no need to carry out vacuum/nitrogen replacement process. Both hands can go straight in and out of the inner anaerobic chamber.

Control system: a full range of real-time status checking and alarm functions to ensure normal operation of the equipment.

Formation of anaerobic environment in operation room

1. Place the necessary accessories and instruments according to the requirements, and put two non-toxic plastic bags into the operation room.

2. Adjust the input pressure of mixed gas and nitrogen cylinders, and adjust the pressure-reducing valve to make the input pressure 0.1Mpa.

3. Open the back of the equipment; after the power switch, press the total power button on the control board to energize the equipment.

4. Put 1000g of palladium pellets (sealed) into the operation room, dehumidify by the condensation system, and put in anaerobic indicator.

5. Close the door of the sampling room and vacuum calibration.

6. First replacement of the operating chamber (nitrogen replacement):

7. Repeat the nitrogen flushing process for the second replacement in the operation room, vacuum the sampling room first, and pay attention to the exhaust valve at any time to close the exhaust.

8. The third replacement of the operating chamber (gas mixture replacement) (gas mixture ratio of H2 1/85% H2 1/10% H21/10% CO2/15%):

9. Open the palladium particle deoxidizer in the operation room, turn on the deoxidizing catalytic converter power supply for catalytic deoxidization, and drop a little clean water on the anaerobic indicator strip reaction area. After 1-2 hours, observe its color change, the reaction part of dark blue to light blue for the operation room to reach the anaerobic environment.

10. You set the UV sterilization lamp, indoor sterilization treatment, sterilizationand time.

Precautions

1. The instrument should be installed in a place where the air is quiet and the temperature change is small as far as possible.

2. Before switching on the machine, you should be familiar with and understand the manuals of the instruments and meters and master the correct way of using them.

3. Cultures must be put in the operation room after reaching the absolute anaerobic environment.

4. If there is a failure (stopping the gas and other reasons), the operation room can maintain anaerobic conditions for 12 hours.

5. Pay attention to the gas circuit frequently to see if there is any leakage phenomenon.

6. When changing the gas cylinder, pay attention to tightening the gas pipe to avoid the inflow of oxygenated gas.

7. Vacuum pump should be used according to the requirements and regularly checked and refueled.

8. Stop using and close the total power button and the power switch at the back of the equipment.

Common clinical anaerobes

1. Clostridium: common pathogenic bacteria are Clostridium tetani, Clostridium perfringens, Clostridium botulinum and Clostridium difficile, all of which are strict anaerobes.

2. Porphyromonas Shah and Collins: common pathogenic bacteria are Porphyromonas gingivalis, Porphyromonas pulpis, etc., strictly anaerobic bacteria.

3. Candidiasis: common pathogenic bacteria include Candida albicans, anaerobic bacteria.

4. Lacticacid bacteria: common conditionally pathogenic bacteria are Lactobacillus acidophilus, anaerobic bacteria.

5. Helicobacter: common pathogenic bacteria include Helicobacter pylori, microaerobic bacteria.

6. Campylobacter: common pathogenic bacteria include Campylobacter jejuni, microaerobic bacteria.

CO2 Incubator

Stackable CO2 Incubator

Ultraviolet Sterilization Stackable CO2 Incubator

The principle of the CO2 incubator is its ability to simulate the formation of a growth environment similar to that of cells/tissues in a living organism by forming an environment inside the incubator chamber. Cells/tissues are cultured in vitro with constant acidity (pH: 7.2-7.4), stable temperature (37°C), high relative humidity (95%) and stable CO2 level (5%). CO2 incubators are widely used in the research and production of medicine, immunology, genetics, microbiology, agricultural science, and pharmacology, and have become one of the most commonly used routine instruments in the laboratories of the above fields.

1. Heating method:

Air-jacketed heating and water-jacketed heating systems are precise and reliable, while they both have advantages and disadvantages.

Water-jacketed heating is maintained at a constant temperature by a separate layer surrounding the internal box. In the event of a power failure, the water-jacket system maintains the accuracy and stability of the temperature inside the incubator for a longer period. It is favorable for users who need to maintain stable incubation conditions for a long period in less stable experimental environments (e.g., where there are restrictions on electricity use or frequent power outages).

Gas jacket-type heating is through all over the box within the gas jacket layer of the heater directly on the inner box body for heating. Compared with the water jacket type, the gas jacket type has the characteristics of fast heating and rapid temperature recovery than the water jacket type incubator, especially favorable to short-term culture and the need for frequent opening and closing of the door of the incubator culture.

2. Temperature control system:

Maintaining a constant temperature in the incubator is important in maintaining healthy cell growth. Therefore, an accurate and reliable temperature control system is indispensable to the incubator. In order to make the incubator work more stably, you can choose an incubator with temperature control, over-temperature alarm control, and ambient temperature monitoring.

3. Temperature uniformity:

Carbon dioxide incubator temperature uniformity within the box is also the main factor that users need to consider. Generally equipped with a fan in the box as well as the air duct of the incubator, uniformity is much better. At the same time, this device also helps the box temperature, CO2 concentration, and relative humidity of the rapid recovery.

Lighting Incubator

An illumination incubator is a box-type equipment with temperature and light control functions to provide an ideal experimental environment for users. Light incubators are high-precision, constant-temperature equipment with light functions, mainly used for plant culture. Light incubator shell is generally cold-rolled steel plate, the surface of the electrostatic spraying process, the inner liner for the engineering plastics or stainless steel, the polyester foam forms the insulation layer, light transmittance window using double-layer hollow glass to ensure that the box thermal insulation performance, the box body inside the cold, hot air ducts, the box gas circulation is smooth, the temperature is more uniform.

Usage of Light Incubator

The light incubator can be programmed to set the temperature, light intensity and time to simulate the day and night environment. It can be used for germination, seedling, tissue and microbial cultivation of plants; rearing of insects and small animals; and determination test of BOD for water body analysis. It is the ideal test equipment for biological genetic engineering, medicine, agriculture, forestry, environmental science, animal husbandry, aquaculture and other production and scientific research departments.

The main parameters of light incubator

1. Temperature control range: 10-50℃ with light, 0-50℃ without light;

2. Temperature resolution: 0.1℃;

3. Temperature fluctuation: ±1℃;

4. Humidity control range: 50-90% RH (the difference between artificial climate chamber and light incubator; light incubator generally does not control humidity);

5. Humidity deviation: ±5-7%RH;

6. Light intensity: 0-12000LX, 0-20000LX, 0-25000LX, 0-30000LX;

7. Programmable control function: temperature, humidity, light intensity set separately, can be set up to 30 segments of the program each set time range of 1-99 hours;

8. Continuous operation time: can be a long continuous operation (two sets of imported original hermetic compressors automatically switch in turn).

Shaker Incubator

Constant Temperature Shaking Incubator

Horizontal Shaking Incubator

A thermostatically controlled shaker incubator is another device used to culture microorganisms. Its advantages are that it transfers heat quickly and evenly to the culture vessel and its agitation increases aeration, thus accelerating growth. However, this incubator can only be used for broth or liquid media.

Uses of Laboratory Incubators

Lab incubators have a wide range of applications in various fields, such as cell culture, drug research, hematology research, and biochemical research.

1. Lab incubators are used to grow microbiological cultures or cell cultures.

2. Lab incubators are also used to maintain cultures of organisms for later use.

3. Some laboratory incubators are used to increase the growth rate of organisms with extended growth rates in natural environments.

4. Specific incubators are used for the propagation of microbial colonies and subsequent determination of biochemical oxygen demand.

5. These are also used in zoology for the propagation of insects and incubation of eggs.

6. Lab incubators also provide controlled conditions for storage of samples before processing in the laboratory.

Precautions when using the lab incubator

As microorganisms are susceptible to temperature changes, temperature fluctuations inside the cabinet caused by repeated opening of the door should be avoided.

The parameters required for the growth of the organisms should be met before the plates are placed in the cabinet.

Plates should be inverted with the lid at the bottom to prevent water condensation on the media.

Interior of the incubator should be cleaned regularly to prevent microorganisms from being deposited on the shelves or corners of the lab incubator.

Sterile water should be placed under the shelves to prevent drying of the medium when the incubator is operated for long periods of time.

English

English