Vertical laminar flow cabinet provides sample protection as purified air travels across the working zone of the cabinet in a vertical, unidirectional stream and leaves the main work chamber across the entire open front of the cabinet.

Most vertical laminar flow cabinets also have perforations at the back wall of the work zone which are designed to eliminate air turbulence and the possibility of dead air corners in the work zone.

Vertical Laminar Flow Cabinet Features:

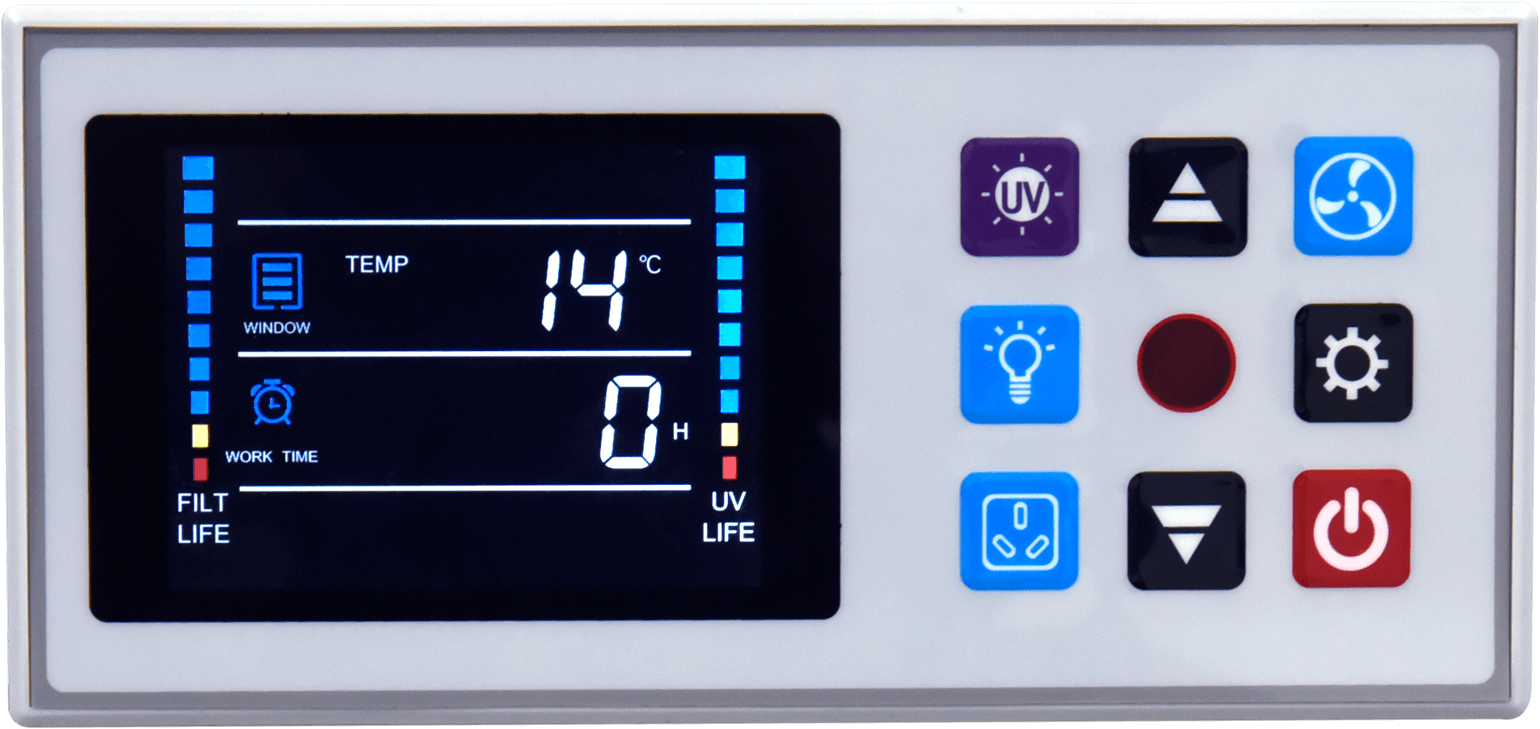

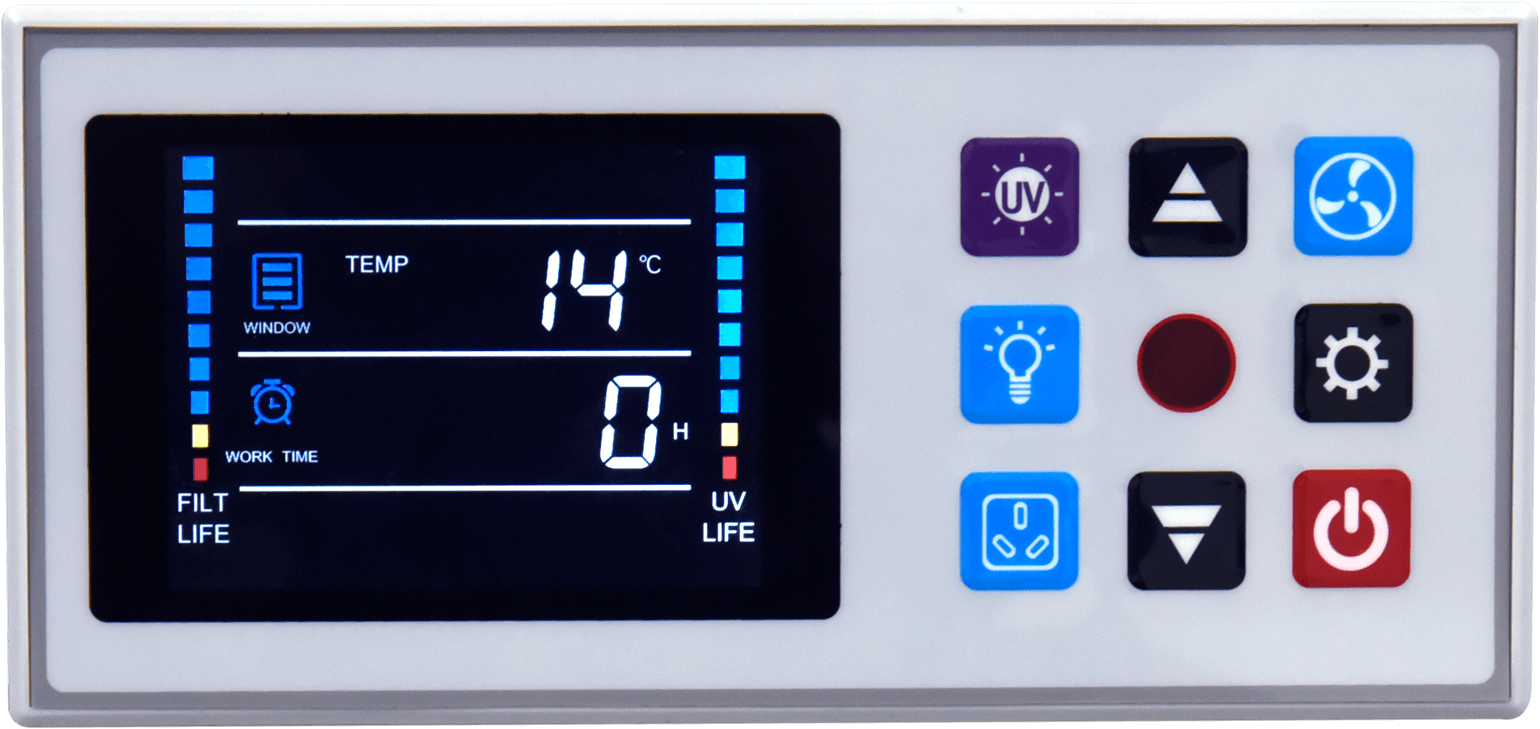

Ergonomic control panel location, centered and angled down for an easy reach & viewing.

Brushed stainless steel work surface is for easy cleaning.

The non-direct light source design can effectively relieve the operator's visual fatigue under the condition of ensuring the illumination.

Intuitive and easy-to-use microprocessor controller with LCD display, graphical and digital display of the operating status of each function, such as filter life, UV life etc.

Reliability:

Front sliding sash interlock with fan and UV lamp.

UV sterilization with UV lamp timing function.

Front sash and side windows are made of UV-resistant tempered glass.

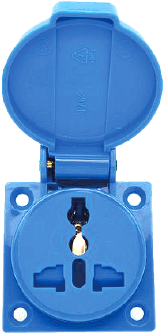

The host and sockets have independent capacitors to prevent current overload.

Memory function in case of power-failure.

Convenience:

HEPA filter and UV life indicators facilitate a timely replacement plan .

Two side glass windows installed for easy experiment observation.

Easy-to-change pre-filter installed could extend the HEPA filter’s lifetime.

Equipped with temperature sensor to show the real temperature during operation.

Waterproof socket provide convenience for small instruments to be used in the operating area.

Vertical Laminar Flow Cabinet Specifications:

| Model | LCB-V1100 | LCB-V1300 | LCB-V1600 | LCB-V1900 |

| External Size (WxDxH)(mm) | 1050x710x1850 | 1320x710x1850 | 1625x710x1850 | 1930x710x1850 |

| Internal Size (WxDxH)(mm) | 950x615x625 | 1220x615x625 | 1525x615x625 | 1830x615x625 |

| Work Surface Height | 750mm |

| Control System | Display | Microprocessor controller with LCD display, display the operating status of each function |

| Interlock | Front sliding sash interlock with fan and UV lamp |

| Life Indicator | HEPA filter and UV life indicators facilitate a timely replacement plan |

| Airflow System | Airflow Velocity | 0.2~0.5 m/s, speed adjustable |

| Air filtration System | Pre-Filter | 1pcs, Polyester fiber,washable |

| HEPA Filter | 1 pcs, Efficiency: > 99.995% at particle size of 0.3μm |

| Cleanliness Grade | ISO Class 5 (formerly Class 100) |

| Partial air circulation | Perforations at the back wall of the work zone which are designed to eliminate air turbulence and the possibility of dead air corners in the work zone. |

| Cabinet Construction | Main Body | Electro-Galvanized steel with antimicrobial powder coating |

| Work Surface | 304 Stainless steel |

| Front Window | Manual sliding sash: 5 mm UV resistant tempered glass with counter-balance system and ergonomic handle |

| Side window | 5 mm UV resistant tempered glass |

| Electrical System | UV Lamp | 20W×1 | 30W×1 | 30W×1 | 20W×2 |

With timing function from 0 to 999 minutes, Interlock with front sliding sash.

Emission of 253.7 nanometers for best sterilization effect. |

| LED Lamp | 6.5W×1 | 9.6W×1 | 9.6W×1 | 6.5W×2 |

| Consumption | 155W | 285W | 285W | 300W |

| Not include socket loading power consumption |

| Power Supply | AC220V±10%, 50/60HZ; 110V±10%, 60Hz |

| Illumination | ≥900Lux |

| Sound Emission | ≤65dB(A) |

| Standard Accessory | 1. Base Stand; 2. LED Lamp; 3. UV Lamp; 4. Waterproof Socket×2 |

| Optional Accessory | Gas Tap |

| Gross Weight (kg) | 178 | 255 | 285 | 330 |

| Shipping Size (W×D×H)(mm) | 1200x930x1330 | 1460x990x1325 | 1765x990x1325 | 2070x990x1325 |

| Shipping Volume (m³) | 1.56 | 1.92 | 2.3 | 2.7 |

LCD Display

(Real-time show the Time, Temperature, UV life and Filter life)

HEPA Filter

UV Lamp

Waterproof Socket (IP54)

Gas Tap (Optional)

Laminar Flow Cabinet Detail:

The laminar flow cabinet has a simple and elegant design with a clear glass panel for easy viewing of the operating area. The control panel includes functions such as air speed adjustment and lighting on/off switch for user-friendly operation.

Packing & Delivery

Adopting standard international export packaging, the packaging can adapt to long-term international transportation.

We provide sea freight, air freight, land freight, express service, accept EXW, FCA, FAS, FOB, CFR, CIF, CPT, CIP, DAF, DES, DEQ, DDU, DDP and other trade terms.

Pre-sale services

●24-hour quick response to customer inquiries.

●Recommend models that meet customer requirements.

●Provide competitive prices and detailed product parameters and related information.

●Provide product customization services.

●Sample testing support, production view service.

After-sales service

●Product installation and use training.

●Provide overseas maintenance services in response to customers technical problems.

●Three-year warranty on air protection products,Life time maintenance service.

●Online and offline technical personnel training services.

FAQ

What is a laminar flow cabinet used for?

A laminar flow cabinet, also referred to as a laminar clean bench, offers a sterile workspace for tasks like media plate preparation and handling samples. It is important to note that this cabinet is not suitable for tasks involving infectious materials, as it does not provide protection to users.

What is difference between laminar air flow and biosafety cabinet?

Laminar flow cabinets differ from biological safety cabinets in that they exclusively offer protection for products by creating a positive pressure airflow environment, either horizontally or vertically. It's important to note that laminar flow cabinets do not ensure protection for personnel or the surrounding environment.

English

English