Vertical Laminar Flow Cabinet Advantage:

Microcomputer control:

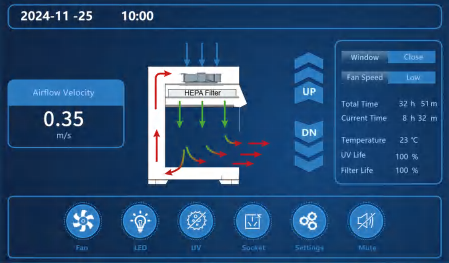

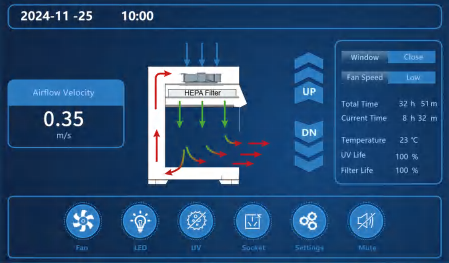

Touch screen control and LCD display of human-machine interaction interface.

Real-time monitoring and display of front window status, real-time display of operating status of each unit.

Display date, time, ambient temperature, HEPA filter life, UV lamp life.

UV disinfection and sterilization function and its timing function can be set by appointment.

Safety status display and sound and light alarm prompt function as well as operation log and alarm log query and viewing function.

Three-level login management authority, control function setting, parameter setting and hierarchical menu entry can be performed.

With memory function in case of power failure, the function before power failure will be automatically executed after power is restored.

Humanized design:

Removable stainless steel working surface, easy to pull out, convenient for cleaning and disinfection.

Transparent side glass window design, which is convenient for multi-angle observation.

The inclined operating front window design conforms to the ergonomic 10° inclination angle to improve the operating comfort.

The base stand and casters with leveling function, easy to move and fix safely.

Low-noise design, energy-saving AC blower with built-in thermal protection, safe and efficient.

Antibacterial material coating, effectively inhibits the growth of microorganisms on the surface of the cabinet.

Built-in Air Velocity Sensor, real-time monitoring and display air velocity and precise control.

Equipped with dual filters, the Pre-filter effectively increases the service life of the HEPA filter.

Safety design:

Blower overheat and overload protection function;

UV lamp button protection function;

Automatic Motorized tempered glass front window, control limit and travel limit dual protection;

Front window descent delay function, sound reminder to prevent pinching.

Audio and visual alarm (Abnormal airflow velocity, HEPA filter failure, UV lamp failure, Front window at unsafe height).

Interlock function: UV lamp and front window; UV lamp and blower, LED lamp; blower and front window.

Optional upgrade LED lamp can be choosed:

Color Rendering Index up to Ra98, Truly restore the true color of the experimental object, the experimental results are more accurate.

RG0 without blue light, protects the operator from blue light.

Vertical Laminar Flow Cabinet Specification:

| Model | LCB-V800I | LCB-V1100I | LCB-V1300I | LCB-V1500I | LCB-V1800I |

| External Size (W×D×H)(mm) | 800×750×1870 | 1100×750×1870 | 1300×750×1870 | 1500×750×1870 | 1800×750×1870 |

| Internal Size (W×D×H)(mm) | 700×660×560 | 1000×660×560 | 1200×660×560 | 1400×660×560 | 1700×660×560 |

| Max Opening | 300 mm |

| Work Surface Height | 730 mm |

| Control System | Display | LCD touch screen |

| Alarm | Audio and visual alarm (Abnormal airflow velocity, HEPA filter failure, UV lamp failure, Front window at unsafe height) |

| Airflow System | Airflow Velocity | 0.3-0.5m/s, speed adjustable |

| Air Volume | 794 m³/h (467CFM) | 1134 m³/h (667CFM) | 1361 m³/h (801CFM) | 1588 m³/h (934CFM) | 1928 m³/h (1135CFM) |

| Air filtration System | Pre-Filter | 1pcs, Polyester fiber,washable, Filtration efficiency: G3 |

| HEPA Filter | 1 pcs, Efficiency: > 99.995% at particle size of 0.3μm |

| Cleanliness Grade | ISO Class 5 (formerly Class 100) |

| Partial air circulation | Perforations at the back wall of the work zone which are designed to eliminate air turbulence and the possibility of dead air corners in the work zone. |

| Cabinet Construction | Main Body | Electro-Galvanized steel with antimicrobial powder coating |

| Work Surface | 304 Stainless Steel |

| Front Window | Automatic Motorized door, tempered glass, Thickness: 5mm |

| Side window | 5 mm UV resistant tempered glass |

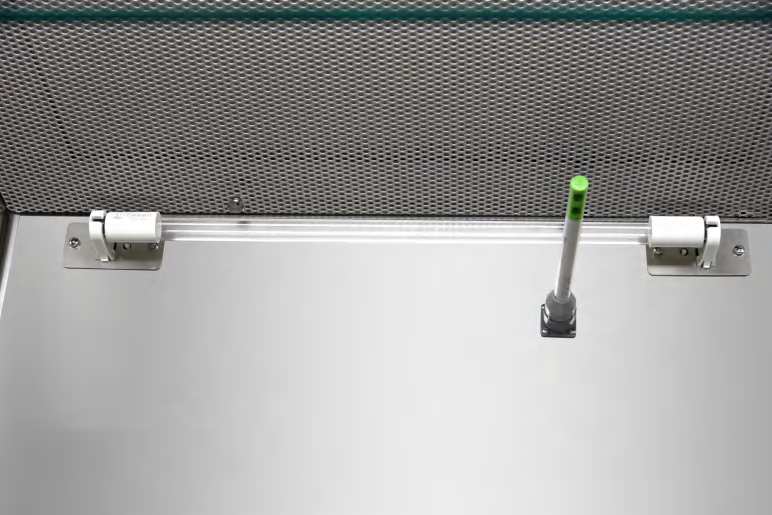

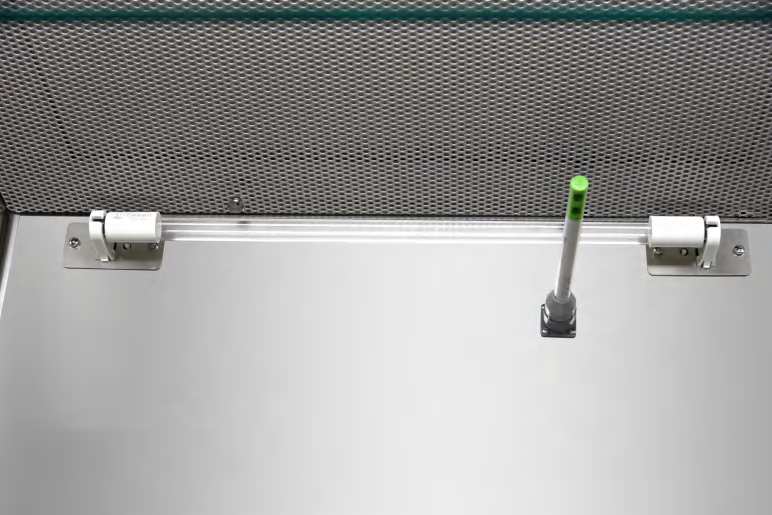

| Electrical System | UV Lamp | 8W×1 (Emission of 253.7 nanometers for best sterilization effect) | 30W×1 (Emission of 253.7 nanometers for best sterilization effect) | 40W×1 (Emission of 253.7 nanometers for best sterilization effect) |

| LED Lamp | 8 W×1 | 10 W×1 | 20 W×1 |

| Max.Consumption | 350 W | 360 W (Not include socket loading power consumption) | 370 W |

| Power Supply | AC220V±10%, 50/60HZ; 110V±10%, 60Hz |

| Illumination | >580 Lux |

| Sound Emission | <64 dB(A) |

| Standard Accessory | 1.Air Velocity Sensor×1; 2.Pre-Filter×1; 3.HEPA Filter×1; 4.Waterproof Socket×2; 5.LED Lamp×1; 6.UV Lamp×1; 7.Base Stand. |

| Optional Accessory | 1.Foot Switch; 2.Gas Tap; 3.Differential Pressure Sensor; 4.ULPA Filter; 5.Manually Adjustable Base Stand; 6.Upgraded LED Lamp |

| Gross Weight (kg) | 190 | 220 | 250 | 280 | 300 |

| Shipping Size (W×D×H)(mm) | 950×1050×1620 | 1250×1050×1620 | 1450×1050×1620 | 1650×1050×1620 | 1950×1050×1620 |

| Shipping Volume (m³) | 1.7 | 2.2 | 2.4 | 2.9 | 3.4 |

Vertical Laminar Flow Cabinet Accessorie:

LCD touch screen (Real-time monitoring and display front window status/Velocity/Pressure. Date/Time/Temperature/filter and UV lamp life/System working status etc.)

Air Velocity sensor (Standard)(Precise control of downflow velocity, even if the filter resistance doubled, it also can maintain constant air velocity.)

Waterproof Socket (IP54)

Foot Switch(optional)

Optional upgrade LED lamp

Vertical Laminar Flow Cabinet Detail Packing & Delivery:

Adopting standard international export packaging, the packaging can adapt to long-term international transportation.

We provide sea freight, air freight, land freight, express service, accept EXW, FCA, FAS, FOB, CFR, CIF, CPT, CIP, DAF, DES, DEQ, DDU, DDP and other trade terms.

FAQ

What is a laminar flow cabinet used for?

A laminar flow cabinet, also referred to as a laminar clean bench, offers a sterile workspace for tasks like media plate preparation and handling samples. It is important to note that this cabinet is not suitable for tasks involving infectious materials, as it does not provide protection to users.

What is difference between laminar air flow and biosafety cabinet?

Laminar flow cabinets differ from biological safety cabinets in that they exclusively offer protection for products by creating a positive pressure airflow environment, either horizontally or vertically. It's important to note that laminar flow cabinets do not ensure protection for personnel or the surrounding environment.

English

English