Ultrasonic baths are indispensable in laboratory research, medical institutions and other fields. It can be used to deep clean and sterilize medical or laboratory instruments, such as tweezers, clamps, scalpels, etc. You can use the Ultrasonic bath to clean and sterilize an object's most complex and hidden parts. Using ultrasound makes it possible to release a huge amount of energy during the cleaning process, quickly reaching the complex and hidden parts of the object. This is the biggest advantage of ultrasonic baths over traditional cleaning methods. Let's move on to understand better how it works, what it is used for and how to choose.

What is an ultrasonic bath

Ultrasonic bath is an alternative name for ultrasonic cleaners. The "bath" part of an ultrasonic bath refers to the liquid or solvent solution in the tank, while the "ultrasonic" part refers to the method of cleaning using high-frequency sound waves.

How does an ultrasonic bath work?

When using an ultrasonic bath to clean parts, the parts are usually placed in a basket, which is then immersed in the bath. This is very advantageous for cleaning parts with blind structures.

The main working process of an ultrasonic cleaner: First high frequency ultrasonic waves are generated in a liquid medium (usually water or a cleaning solvent). The waves then cause the liquid to cavitate and the resulting bubbles explode near the surface of the cleaned object and release intense energy. These exploding tiny bubbles clean out bacteria, dirt and other contaminants adhering to complex structures such as blind holes and grooves.

*Cavitation: High-frequency ultrasound causes tiny bubbles to form in the liquid phenomenon known as cavitation.

*Aeration: Bubbles continue to form and burst under ultrasonic waves, releasing a huge amount of energy in the process known as aeration.

Important components of ultrasonic bath

The important components of an ultrasonic bath include the cleaning bath, generator and transducer.

Cleaning Tank: Usually made of corrosion-resistant material, it mainly contains the cleaning solution and the items to be cleaned.

Generator: This is the core component of the machine and its main function is to convert AC energy into ultrasonic electrical signals. It usually has a frequency and power adjustment function in order to meet the different cleaning needs.

Transducer: The transducer converts the ultrasonic electrical signal into mechanical energy (ultrasonic oscillation) and transfers the energy to the objects to be cleaned through liquid conduction.

What is an ultrasonic generator?

We can think of a generator as a power source that sends pulses of high-voltage electrical energy primarily to a transducer.

What is an ultrasonic transducer?

A transducer usually consists of a source element (piezoelectric crystal), a backing and a radiating plate.

The piezoelectric crystal converts the electrical energy transmitted from the generator into ultrasonic energy through the piezoelectric effect.

The backing absorbs the energy radiated from the back of the piezoelectric crystal.

The radiating plate converts the ultrasonic energy generated by the piezoelectric crystal into mechanical (pressure) waves in the fluid. The final device that produces an acoustic sound above the range of human hearing is also known as ultrasonic vibration.

Advantages of ultrasonic cleaning machine

Ultrasonic cleaning provides an efficient and safe solution for blind holes or parts with complex structures that are difficult to clean in experimental and medical equipment. It can quickly clean irregular surfaces or small crevices without causing damage to the surface of the equipment. It offers the following advantages over traditional cleaning methods:

Easily removes many contaminants, including bacteria, dust, pigments, oxides, etc., ensuring an effective and thorough cleaning.

Cheap to maintain and easy to operate

Many parts can be cleaned simultaneously, saving staff time and efficiency.

The entire process does not require using sharp tools to touch the parts' surface, so the parts' integrity is guaranteed.

What does an ultrasonic bath do?

Ultrasonic cleaners are popular in the medical, laboratory, electronics, jewelry, and dental clinic industries. The following items are recommended as suitable for ultrasonic cleaning:

Glassware: beakers, test tubes, etc.

Steel utensils: tweezers, scissors, pliers, screwdrivers, etc.

Plastic items: Petri dishes, centrifuge tubes, PCR tubes, etc.

Sieves: filters, sieves, glass fiber cartridges, filter membranes, separating funnels and funnel sieves.

Jewellery, bracelets, earrings, etc.

Dental equipment and surgical instruments

The exact frequency and duration of cleaning depends on the difficulty of cleaning the dirt and the material, with daily cleaning times ranging from 3 to 6 minutes. After the cleaning is completed, the washing machine usually has the option of heating and drying.

Items not suitable for ultrasonic cleaning:

Flammable, explosive, fragile products

Sensitive electronic equipment

Textiles such as wool, silk, etc.

Gold-plated, silver-plated and other metal-plated jewellery

Buying an ultrasonic cleaning machine requires attention

When shopping for an ultrasonic cleaning machine, you may find that the prices of many seemingly identical machines vary greatly. Many manufacturers offer lower prices to make their products more competitive, and it often sacrifices the quality of the product. First-time buyers need help realizing these sacrifices in quality and opting for a low-cost ultrasonic cleaning machine. Let's take a look at some of these sacrifices in equipment purchased at low prices:

Transducer: One of the most cost-saving production components in an ultrasonic cleaner is the transducer. Usually, the transducer's quality will show natural functional decay after 4-7 years of use. However, cheaper cleaner transducers usually show a decrease in cavitation capacity within 5-10 months, leading to uneven cleaning.

Generator: As another important component in the ultrasonic bath, its quality can also greatly affect production costs. Low-quality generators can vary greatly in the quality of their work over time. Not only is it difficult to remove contaminants from the part, but it may also damage the surface of the part.

Tank Thickness: The tank is usually located at the bottom of the ultrasonic cleaning machine and contains the cleaning fluid and the items to be cleaned. The thickness of the tank directly affects the cleaning time and service life. Low-quality tanks with increased time will appear to rupture, leakage and other phenomena.

Purchasing Myths

Myth 1: Sweeping cleans parts better. Sweeping refers to cleaning by constantly changing the frequency of the ultrasonic waves. It can clean the surface of parts more comprehensively than the traditional fixed frequency. The cleaner's transducer can be tested and matched to the resonant frequency, and fixed-frequency ultrasonic cleaning is already effective enough. Sweep frequency mode is a waste of energy.

Myth 2: The more fluctuations in the surface of the liquid, the better. Many people believe that the amplitude of the vibration of the liquid determines the quality of ultrasonic cleaning. Still, the surface movement is only ultrasonic energy reflected from the surface of the fluid and has nothing to do with the uniformity of ultrasonic energy.

Myth 3: As long as the tank has ultrasound, power is no longer important. The power in the ultrasonic cleaning machine is still a very important factor, not only with the cleaning effect but also with the cleaning speed and the safety of the items. Avoid choosing a unit with a power ratio of less than 50 watts per gallon.

Ultrasonic Cleaning Equipment

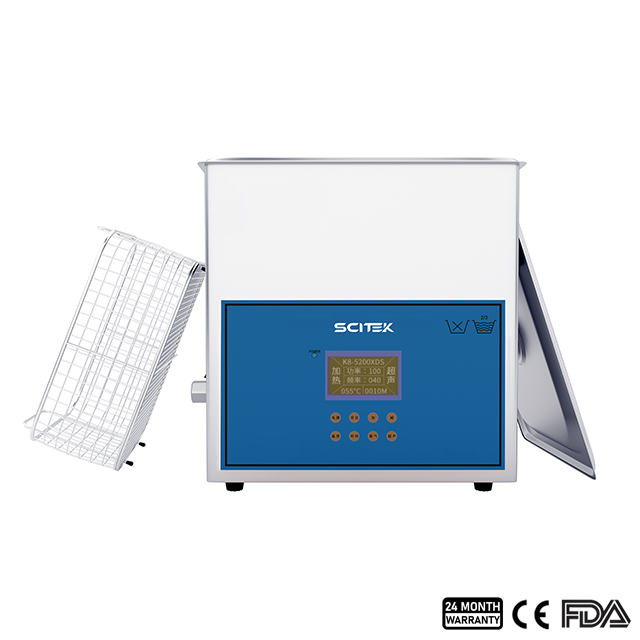

Ultrasonic Bath

Ultrasonic Bath

Capacity(L) : 10, 15, 22.5

Ultrasound Frequency(KHz) : 40

Ultrasonic Power(W) : 200, 400, 500

Power Adjustable(%) : 10-100

Digital Ultrasonic Cleaner

Capacity(L) : 0.6, 1.3, 2, 3.2, 4.8, 4.5, 6.5, 7, 10, 15, 20, 22, 30, 45

Ultrasound Frequency(KHz) : 40

Ultrasonic Power(W) : 50, 70, 120, 180, 240, 360, 480, 600, 720

Multifunctional Ultrasonic Bath

Capacity(L) : 1.3, 2, 3.2, 4.8, 4.5, 6.5, 7, 10, 15, 20, 22, 30, 45

Ultrasound Frequency(KHz) : 40

Ultrasonic Power(W) : 70, 120, 180, 240, 360, 480, 600, 720

Ultrasonic Glasses Cleaner

Ultrasonic Glasses Cleaner

Tank Capacity(L) : 0.4

Chamber Material : ABS+SUS304

Ultrasonic Freq(KHz) : 40KHz

Time Control : Automatic shutdown after 5 minutes

Chamber Size (W×D×H)(mm) : 168x75x40

Household Ultrasonic Cleaner

Tank Capacity(L) : 0.75

Chamber Material : SUS304

Ultrasonic Freq(KHz) : 42KHz

Time Control : 5 working cycles

Chamber Size (W×D×H)(mm) : 150x130x50

Portable Ultrasonic Bath

Tank Capacity(L) : 0.6-5

Chamber Material : High hardness aluminum alloy

Ultrasonic Freq(KHz) : 5KHz

Time Control : 10 minutes

External Size (W×D×H)(mm) : 88x65x40

Ultrasonic Cleaning Baskets

In most cases, ultrasonic cleaning baskets hold parts at a suitable distance from the bottom of the tank. The basket is usually a stainless steel mesh with mesh or solid stainless steel walls. In addition to promoting more effective cleaning, the basket prevents the part from coming into contact with the bottom of the tank. The cleaning basket ensures that parts are evenly exposed to the cleaning solution as they vibrate at ultrasonic frequencies, resulting in more effective cleaning.

Ultrasonic Cleaner Additional Features

A timer helps you set the cleaning time to avoid over-cleaning, which can cause damage to parts.

Temperature control heats the solution to increase cleaning effectiveness.

Scanning mode helps avoid uneven localized cleaning or dead spots by changing the direction and intensity of ultrasonic wave propagation to improve cleaning results.

Degassing mode removes residual air from fresh cleaning solutions and reduces the interference of air bubbles with the cleaning process.

Pulse mode provides pulses of enhanced ultrasonic power to remove stubborn contaminants.

Of course, many other features help ultrasonic cleaning work better and more efficiently, including flask holders, acoustic lids, cooling coils, etc. When purchasing, you can add accessory features according to your needs.

What makes Scitek's ultrasonic cleaners different?

High-quality Piezoelectric crystals: Ultrasonic transducers are made from the highest-quality piezoelectric crystals. Although more expensive to produce, our transducers are guaranteed to last more than 5-6 years before natural degradation occurs.

Self-tuning ultrasonic generator: The generator is self-tuning and can sense the load of the parts in the ultrasonic cleaning tank and adjust the power output according to the load. This also means that when the generators detect attenuation in the transducer, they increase the power output. It is made of high-quality materials designed for continuous manufacturing.

Square wave ultrasonic generator: Compared with sine wave, square wave generator has stronger cleaning ability and can provide strong cleaning effect.

Thick gauge stainless steel: Our stainless steel ultrasonic cleaning tanks are made of thicker stainless steel to withstand the long-term effects of ultrasonic vibration.

Whether in a laboratory, medical facility, manufacturing or other field, Scitek has an ultrasonic bath to meet your needs. We are committed to providing superior products and excellent customer service to provide you with the best possible cleaning solution.

Contact us today to learn more about Scitek's ultrasonic baths and start enjoying an efficient, reliable cleaning experience!

FAQ

How to choose ultrasonic cleaning frequency

| Frequency | Feature | Application |

| 20 kHz - 40 kHz | Relatively large bubbles are produced, which implode more violently and have a stronger impact | Suitable for industrial cleaning, metal processing and other industries

|

| 40 kHz - 100 kHz | Produces medium wavelength and energy, can be uniform cleaning | Experimental and medical industries as well as jewellery and electronic components cleaning

|

| 100 kHz - 1 MHz | High-frequency ultrasound produces shorter wavelengths and lower energy, gentle cleaning | Glasses, electronic chips and other small fragile items |

Is ultrasonic bath safe

Yes

What liquid is used in an ultrasonic bath?

Water is one of the most commonly used liquids, but in some cases, it may be necessary to use specialized cleaning liquids to improve the cleaning effectiveness or to meet specific needs. For example, in the healthcare sector, cleaning may be carried out using liquids containing disinfectants or detergents. Specialized liquids such as corrosives or solvents may be required for cleaning in the industrial sector.

How long does it take to clean

Cleaning time depends on several factors, typically 2-15 minutes, but for particularly stubborn stains, the cleaning time can be increased or the frequency reduced.

Where do ultrasonic cleaning contaminants go?

They remain in the solution.

Contaminants removed during the cleaning process either float to the surface, sink to the bottom or remain in suspension.

English

English