Principle of the Dry Heat Sterilizer:

Under the action of the circulating fan, heating tube, and dehumidifying fan, the dry heat sterilizer rapidly heats up. At the same time, clean and dry air enters the sterilization chamber through a high-efficiency filter, absorbing moisture from the surface of the materials. The absorbed moisture evaporates and is discharged through the circulating channel. The dry air circulates in a directed manner under the action of the fan. As the water vapor gradually decreases, fresh filtered air is intermittently replenished. The chamber is maintained at a slightly negative pressure, and the temperature in the sterilization chamber reaches the set value. It is kept at the set temperature for insulation circulation, achieving sterilization of the sterilized items.

Dry Heat Sterilizer Features:

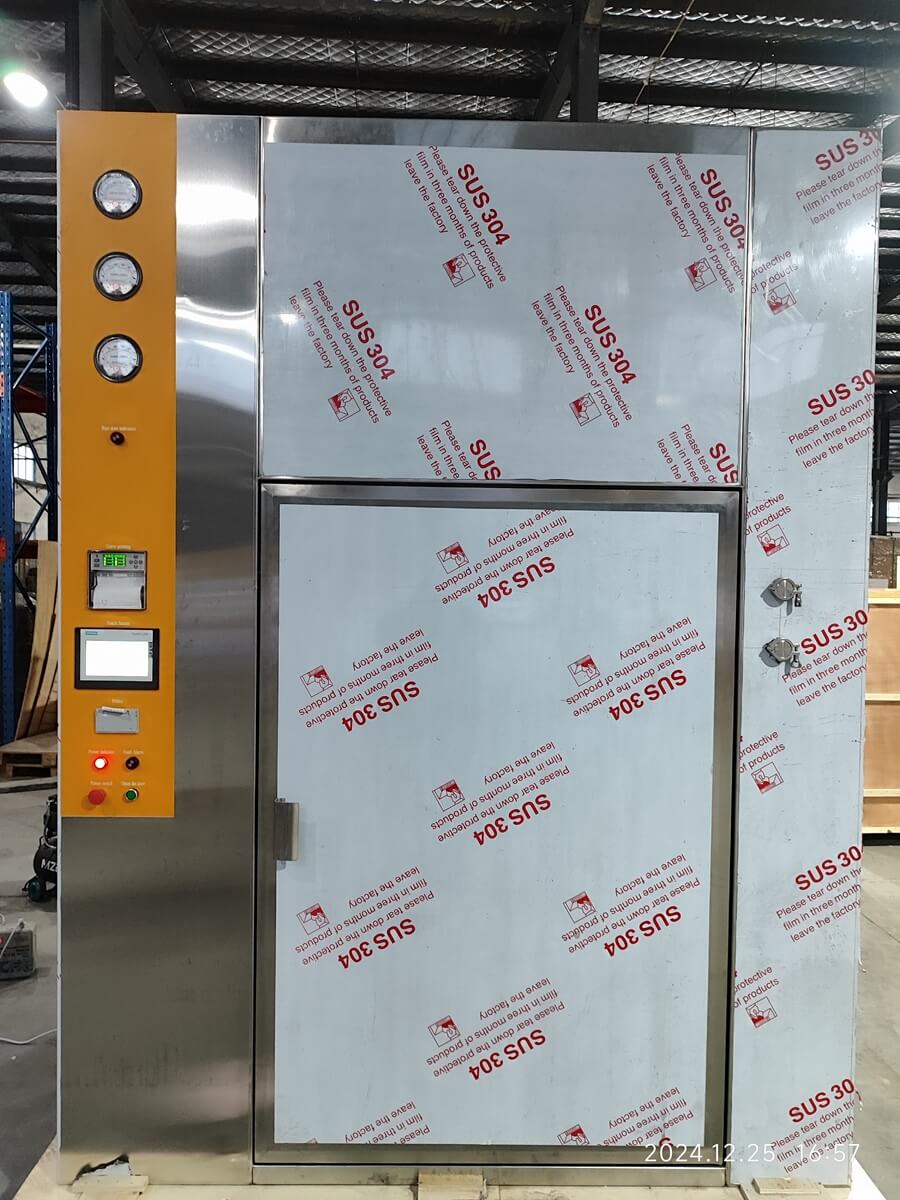

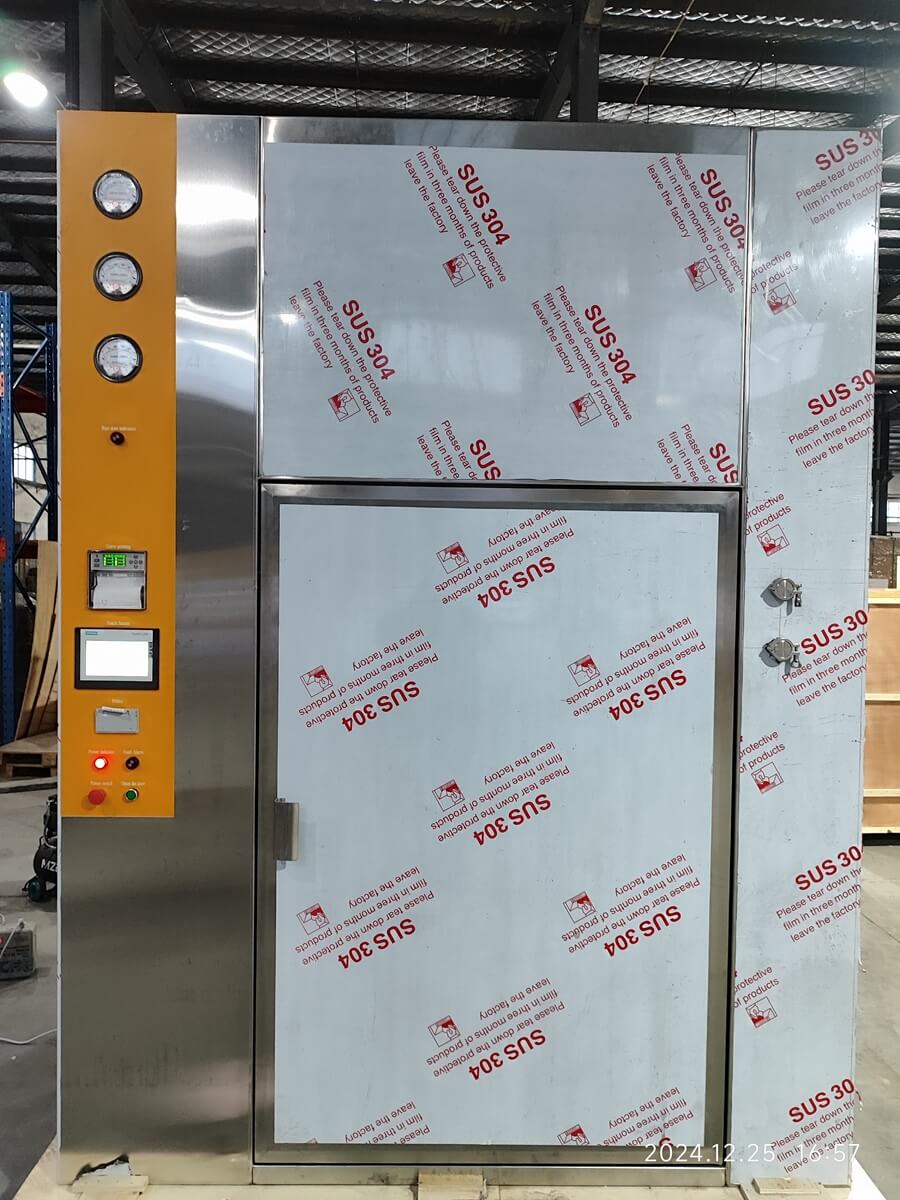

Premium Chamber Material: Crafted from high-quality 304/316L stainless steel, the chamber ensures durability, resistance to corrosion, and facilitates easy cleaning, meeting the stringent requirements of sterilization standards.

Variable Capacities: Dry heat sterilizer offers a range of capacities (360L, 450L, 650L, 800L, 1000L, 1200L, 2000L), providing flexibility to cater to diverse industry needs, from smaller laboratories to large-scale pharmaceutical production.

Powerful Sterilization Capability: With a power supply of 18kVA, the dry heat sterilizer delivers robust and efficient sterilization performance, ensuring the complete elimination of microorganisms and spores.

Wide Temperature Range: Operating in a temperature range from RT to 300℃, dry heat sterilizer accommodates various sterilization requirements, making it suitable for a broad spectrum of applications.

Low Noise Level: The dry heat sterilization process is conducted with minimal disruption, as the noise level is maintained at ≤85dB, ensuring a quiet and conducive working environment.

High Cleanliness Grade: Achieving a cleanliness grade of Class 100, the dry heat sterilizer provides a sterile environment, preventing the introduction of contaminants during the dry heat sterilization process.

Versatile Cooling Options: The dry heat sterilizer offers flexibility with cooling methods, allowing users to choose between Air Cooling and Water Cooling based on their specific requirements and available resources.

Dry Heat Sterilizer Specifications:

| Model | ST-DH360 | ST-DH450 | ST-DH650 | ST-DH800 | ST-DH1000 | ST-DH1200 | ST-DH2000 |

| Chamber Material | 304/316L |

| Capacity(L) | 360 | 450 | 650 | 800 | 1000 | 1200 | 2000 |

| Power Supply | 18kVA | 20kVA | 21kVA | 24kVA | 27kVA | 27kVA | 36kVA |

| Sterilizer Temperature | RT~300℃ |

| Noise | ≤85dB |

| Cleanliness Grade | CLass 100 |

| Cooling Method | Air Cooling/Water Cooling |

Dry Heat Sterilizer Applications:

Dry heat sterilizer finds wide-ranging applications across industries, including:

Pharmaceutical Manufacturing: Ideal for the dry heat sterilization of pharmaceutical equipment, containers, and raw materials, ensuring compliance with rigorous industry standards.

Biotechnology: Suitable for sterilizing laboratory instruments, glassware, and media, maintaining a sterile environment crucial for biotechnological processes.

Healthcare Institutions: Used for the dry heat sterilization of medical instruments, surgical equipment, and other healthcare materials, contributing to infection control measures.

Research Laboratories: Applicable in research settings for the sterilization of tools and equipment critical to experiments and studies.

Food and Beverage Industry: Employed for sterilizing packaging materials, utensils, and equipment in the production and processing of food and beverages.

In summary, dry heat sterilizer combines cutting-edge technology with versatile features, making it an indispensable tool in various sectors where reliable and effective sterilization is paramount.

Details of Dry Heat Sterilizer:

The interior of the unit is made of stainless steel for efficient heating and sterilization.

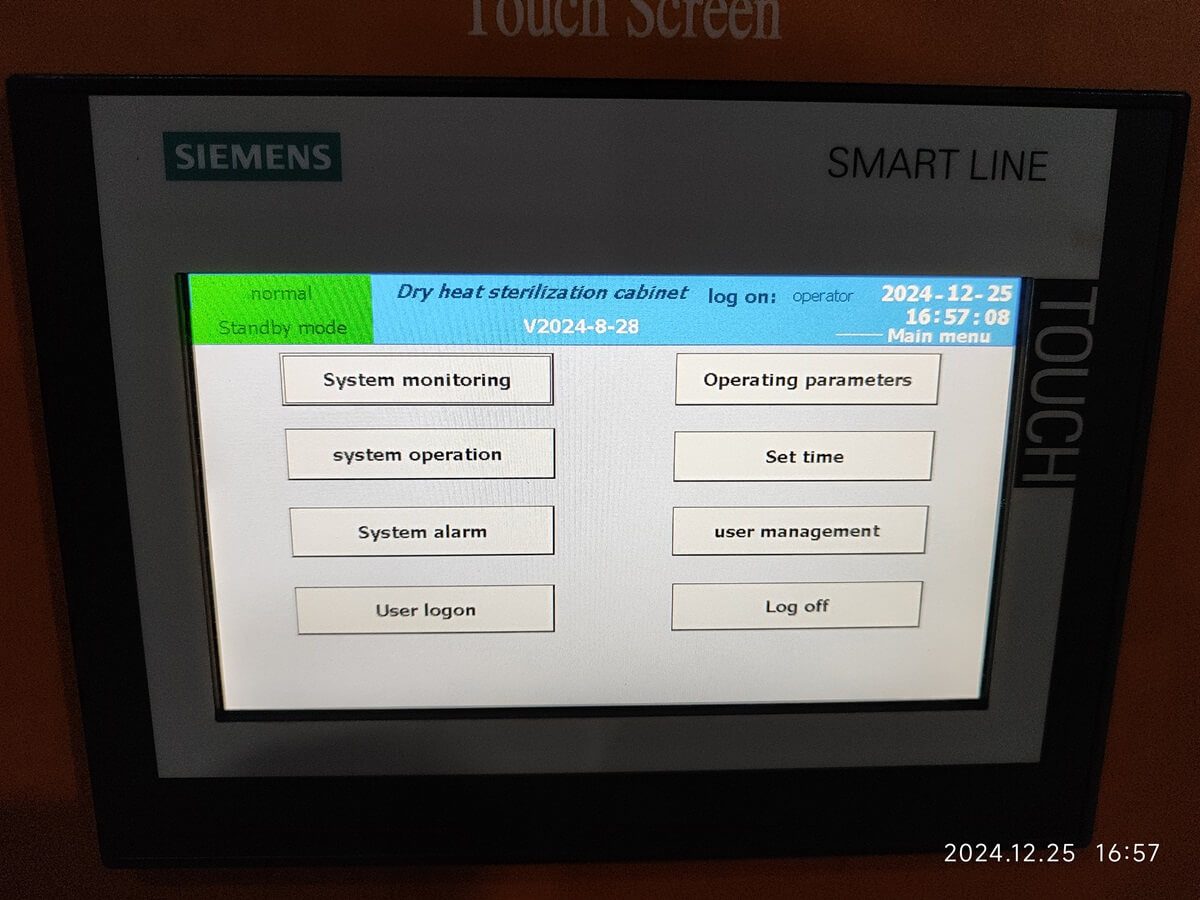

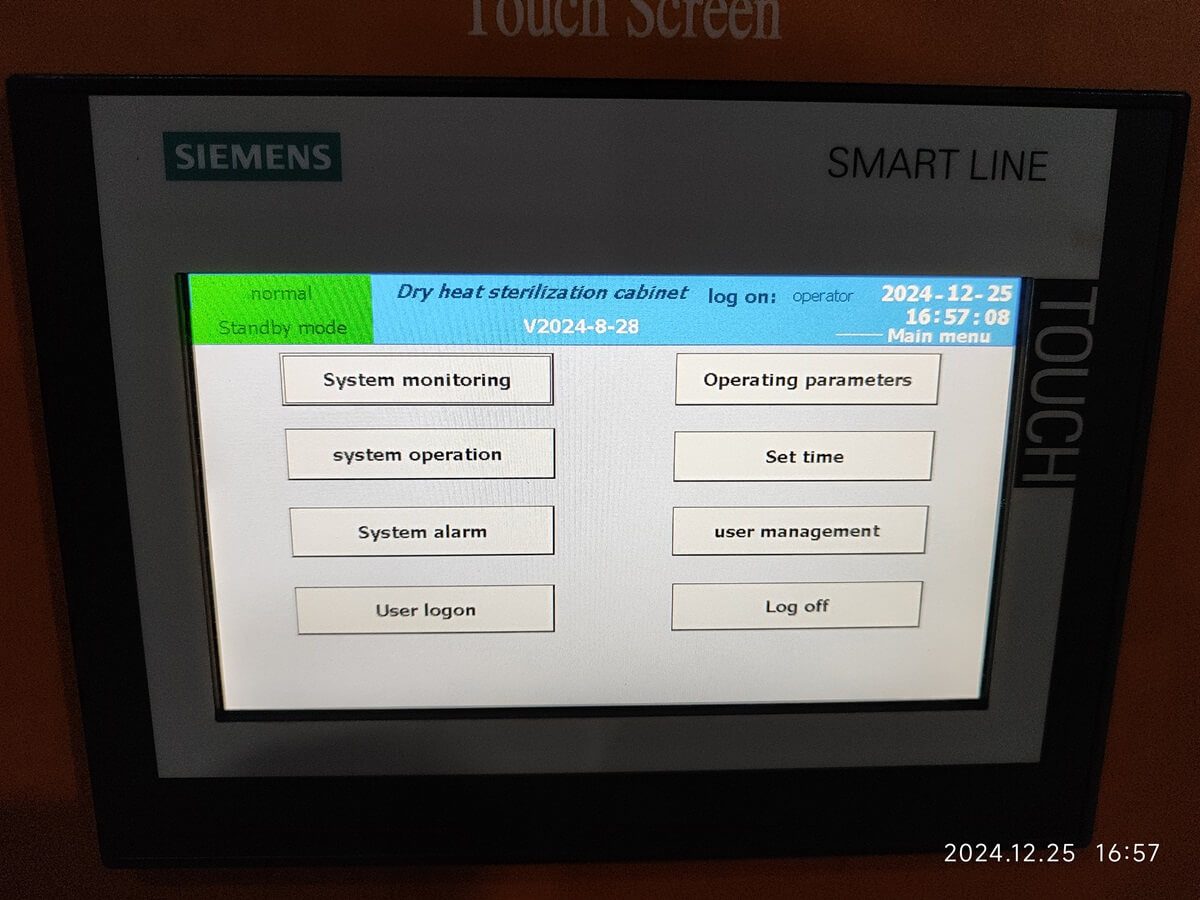

The display screen interface is clear, presenting the current operating status of the equipment, such as temperature, time and other important parameters. The touch screen is easy to operate and displays real-time operating information, making it convenient for users to monitor and adjust working parameters.

The wheels are robustly designed to withstand the weight of the equipment and have a locking function to ensure that the equipment is stable and does not move during use, enhancing ease of use.

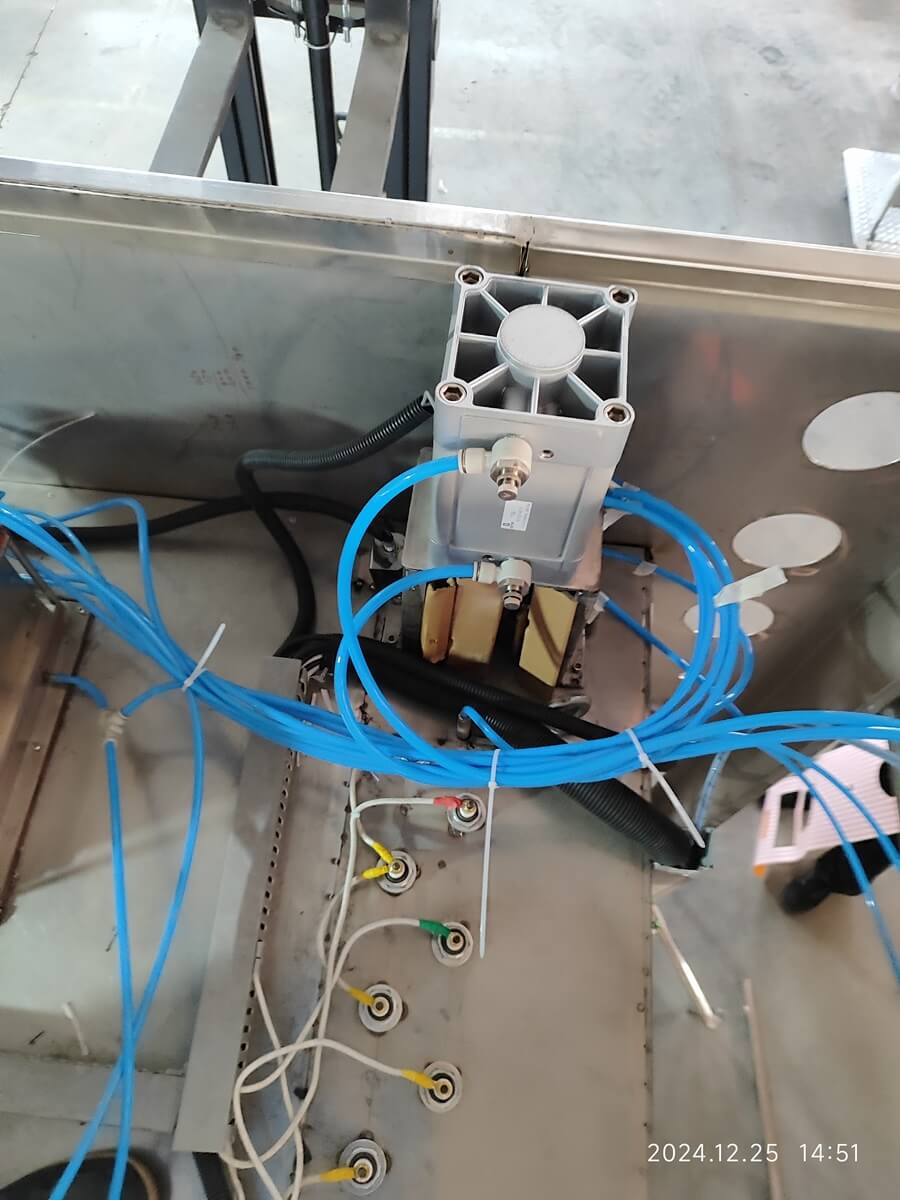

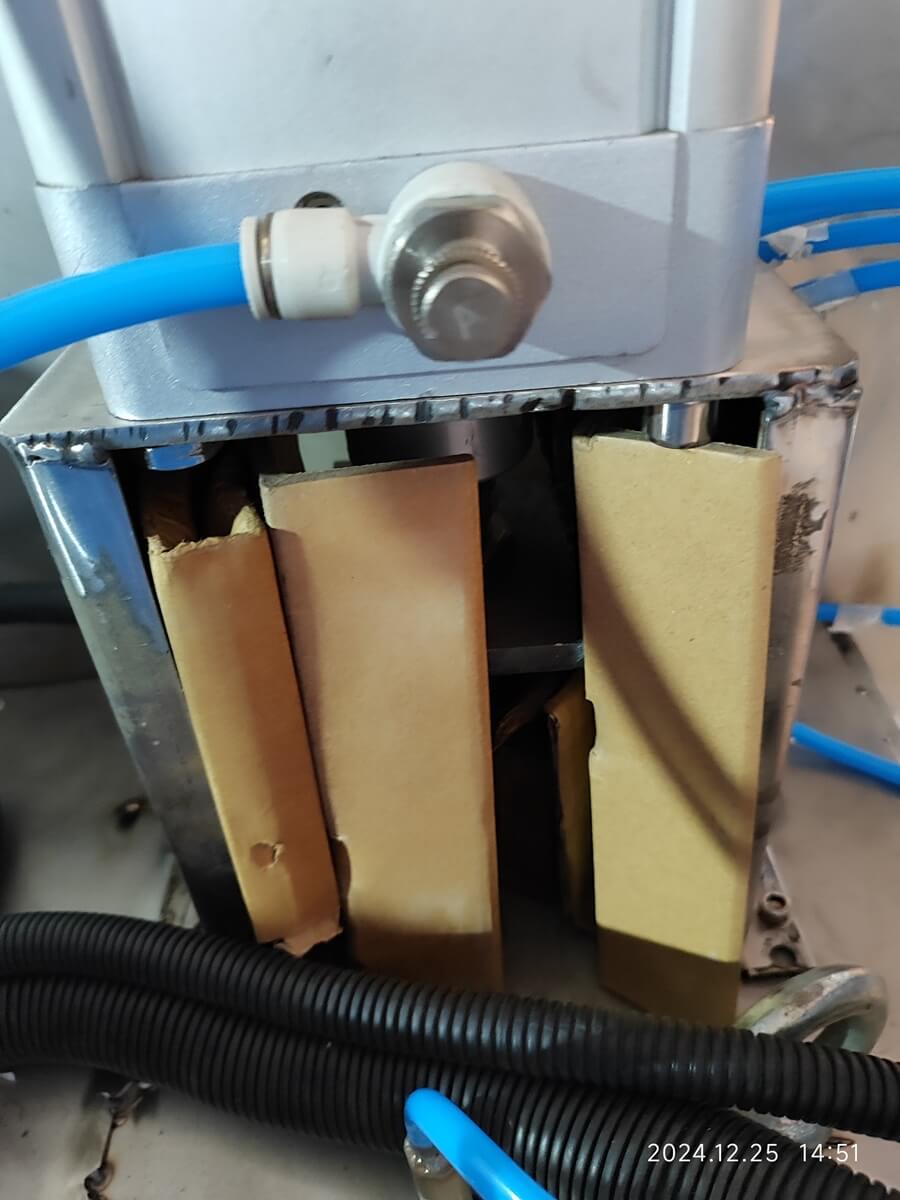

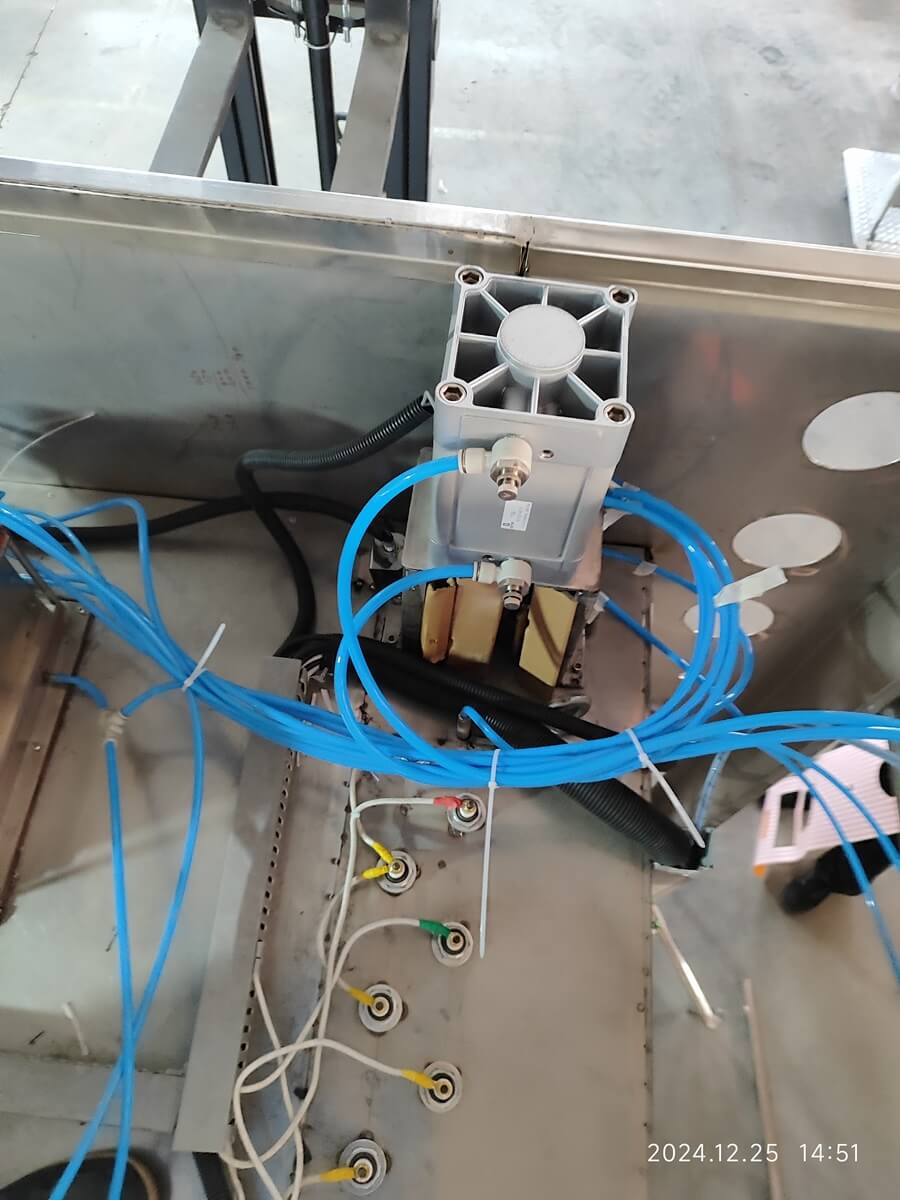

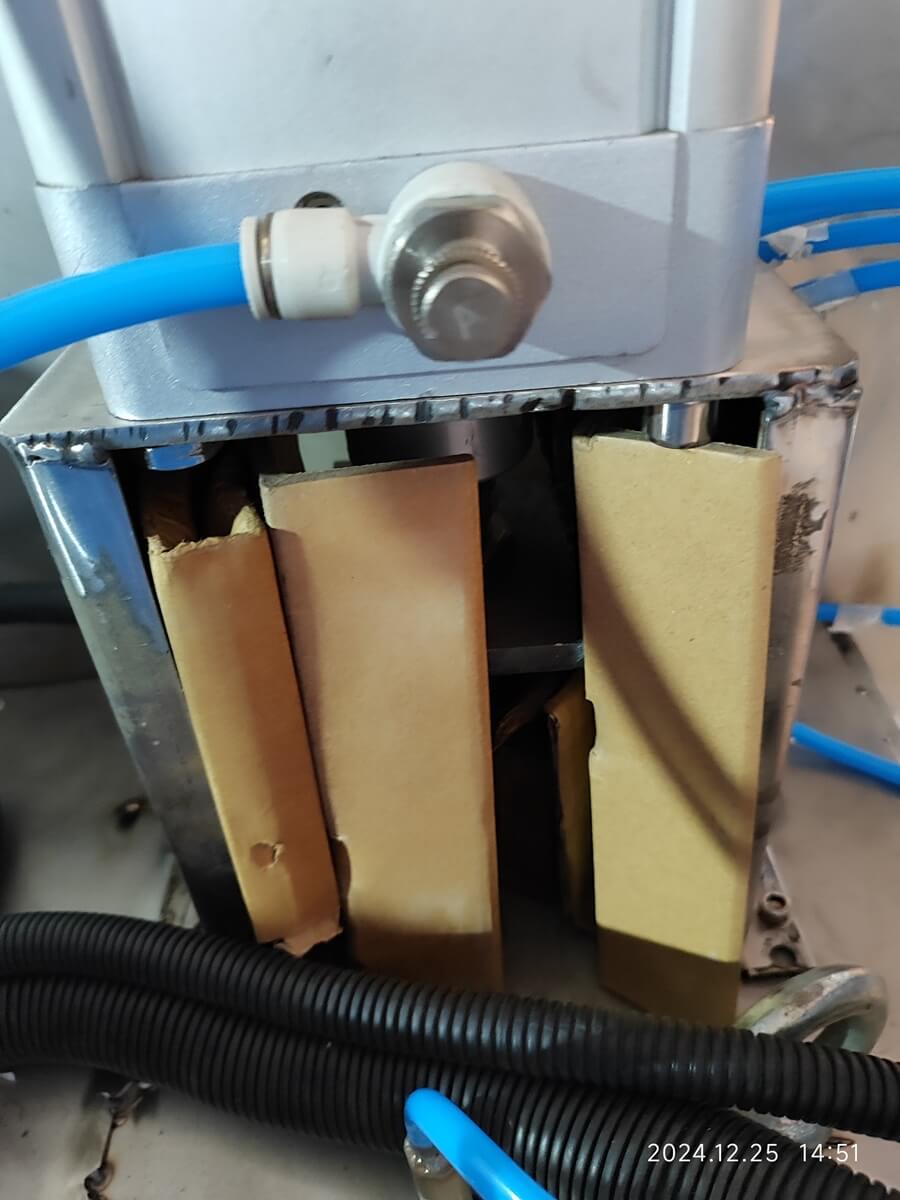

The core components of the Dry Heat Sterilizer, such as the heating system and the transfer piping, are clearly constructed and compactly designed.

The case is strong and well protected to ensure that the equipment is effectively protected during transportation.

WHY SCITEK

24 Months Limited Warranty

CE Standards

1-2 Days Handling and 7-30 Days Shipping

English

English