The ST-B60/80PV series is a type B sterilizer that uses steam as a medium. It achieves sterilization of items by repeatedly extracting vacuum and filling the sterilization chamber with steam to create a certain level of vacuum before introducing saturated steam, reaching the set pressure and temperature to achieve the purpose of sterilization. It is suitable for use in medical and health care departments such as stomatology, ophthalmology, operating rooms, supply rooms, and analysis rooms for sterilizing solid instruments, type A hollow instruments, implantable instruments, dressings and fabrics, rubber catheters, and liquid items.

The non-liquid program is suitable for the sterilization of surgical instruments, solid bare instruments, packaged instruments, rubber loads, etc. The liquid program is suitable for the sterilization of liquids such as water and culture media.

Benchtop Pulse Vacuum Autoclave Specifications:

| Model | ST-B60PV | ST-B80PV |

| Capacity | 60L | 80L |

| Chamber Size(mm) | φ391x521 | φ391x671 |

| Designed Pressure | -0.1/0.3Mpa |

| Sterilization Temperature | 150℃ |

| Wokring Temperature | 121℃/134℃ |

| Water Tank Capacity(L) | 14 |

| Chamber Material | SUS304 |

| Noise | ≤65dB |

| Consumption | 5.8kW | 6.2kW |

| Power Supply | 220V/110V, 50/60HZ |

| External Size(WxDxH)(mm) | 990x804x675 | 1140x805x675 |

| Package Size(WxDxH)(mm) | 1130x960x940 | 1330x960x940 |

| N.W./G.W. (kg) | 175/215 | 185/230 |

Benchtop Pulse Vacuum Autoclave Features:

Control System

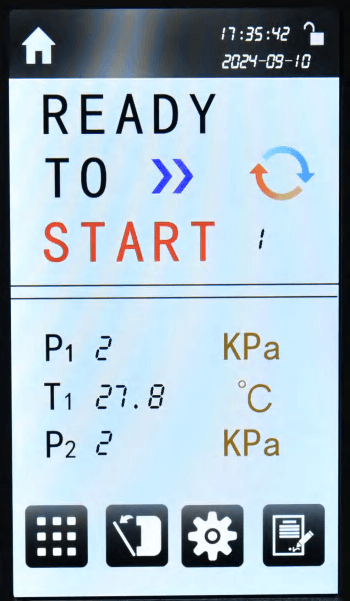

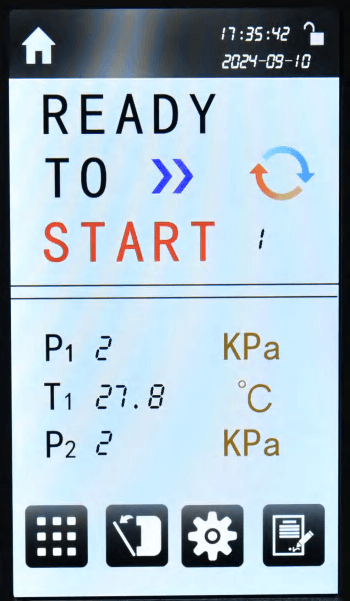

Display:The LCD touch screen can display temperature, pressure, time, operating status, fault alarm, equipment operation curve and other information in real time, making the sterilization information more intuitive and clear, and convenient for users to observe the operating status of the equipment

Process control

The whole process of preheating, replacement, heating, sterilization, exhaust and vacuum drying is automatically operated; it uses steam as the medium, adopts an efficient vacuum pumping system, and repeatedly pumps vacuum to achieve the effect of sterilization and drying.

Multi-point Temperature Control Technology

Non-sealed liquid programs use mobile temperature sensors to measure tempera-ture, which can detect the internal temperature of the liquid in real time, making the internal temperature of the liquid more intuitive and clear.

Insulation Function

The insulation function can be set as needed to achieve liquid culture medium sterilization, culture medium dissolution-insulation function.

Safety Function

With over-temperature automatic protection device, anti-dry burning protection device, over-pressure automatic release device, over-current protection device, electronic circuit safety device

Self-calibration Function

It has a complete background self-calibration system to realize the calibration of system parameters such as pressure and temperature. Without disassembling the instrument, the authorized tool can be used for on-site adjustment.

Independently Installed Pressure Sensors

An independent pressure transmitter is installed in each of the inner chamber and evaporator to ensure that the equipment pressure is within the safe control range

Water Injection and Drainage Method

Automatic water injection, automatic drainage

Pressure Gauge: Range

-0.1~0.5MPa, Accuracy level: 1.6

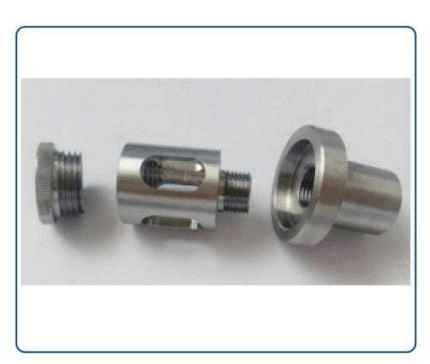

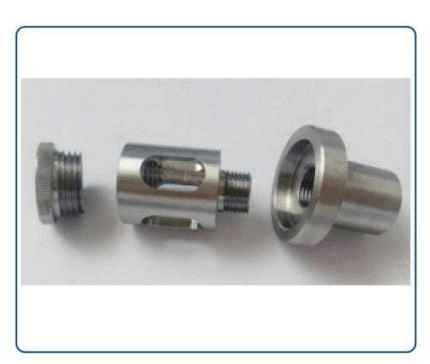

Filter

Manually removable filter, easy to clean, more user-friendly

Sterilization Program:

Encapsulation Program, Rubber Program, Dressing Program, Liquid Program, Liquid customization, Solid customization, as well as B&D testing, Vacuum testing Program, Medium Sterilization & Dissolution

Details of Benchtop Pulse Vacuum Autoclave:

LCD Screen

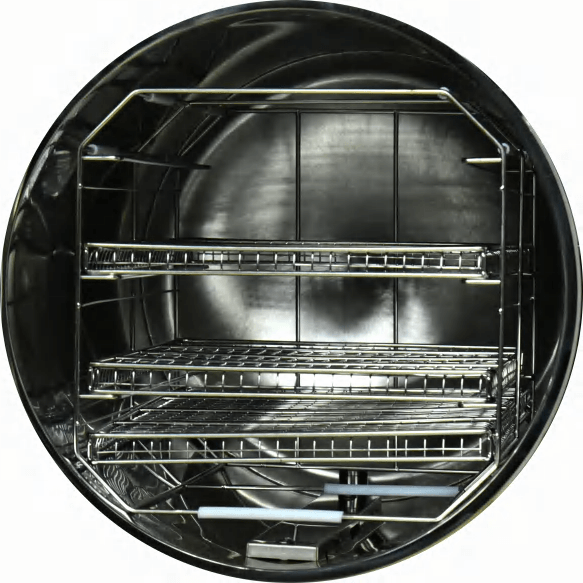

SUS304 Chamber

Quick Detachable Filter

Built-in Water Tank

Built-in Water Tank

Details of Benchtop Pulse Vacuum Autoclave:

ST-B60PV Pulse Vacuum Autoclave

ST-B80PV Pulse Vacuum Autoclave

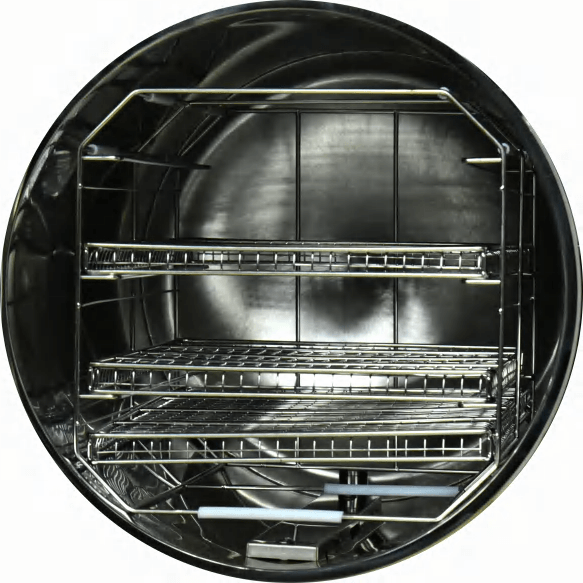

The sterilizer chamber is spacious and can accommodate multiple devices for efficient sterilization. Suitable for batch sterilization of medical equipment, laboratory instruments, etc.

Digital control panel with precise temperature and time control ensures accuracy and consistency of the sterilization process.

The pressure gauge monitors the pressure inside the equipment in real time to guarantee the safety and effectiveness of the sterilization process.

Ventilated grid design at the back of the sterilizer enhances the heat dissipation performance of the equipment and ensures the stability of long-time operation.

Built-in basket racks make it easy to accommodate instruments of different sizes for sterilization, while optimizing the use of sterilization space.

English

English