Vacuum Oven Specifications:

| Model | VO-25D | VO-55D | VO-90D |

| Capacity (L) | 24 | 52 | 91 |

| Heating Mode | Four sides heating |

| Size(WxDxH) | Internal (mm) | 300x300x270 | 415x370x340 | 450x450x450 |

| External (mm) | 480x480x606 | 560x540x680 | 640x590x780 |

| Temperature | Range (℃) | RT+10~250 |

| Fluctuation (℃) | ±1 |

| Resolution (℃) | 0.1 |

| Sensor | PT100 |

| Controller | PID |

| Vacuum Degree Range | <133Pa |

| Vacuum Nozzle Diameter(mm) | Φ10 |

| Display | High efinition LCD |

| Timer | 0~9999min (With timing waiting function) |

| Material | Internal | High-quality hairline stainless steel |

| External | Cold rolled steel electrostatic spraying exterior |

| Shelves(Standard/Max) | 2/4 | 2/6 | 2/7 |

| Safety Device | Over temperaure visible & audible alarm |

| Electricity | Voltage/Frequency | AC 220/110V, 50/60Hz |

| Consumption (W) | 800 | 1400 | 2000 |

| N.W./G.W. (kg) | 42/52 | 67/92 | 82/105 |

| Shipping Size (WxDxH) (mm) | 590x550x750 | 704x620x814 | 739x700x889 |

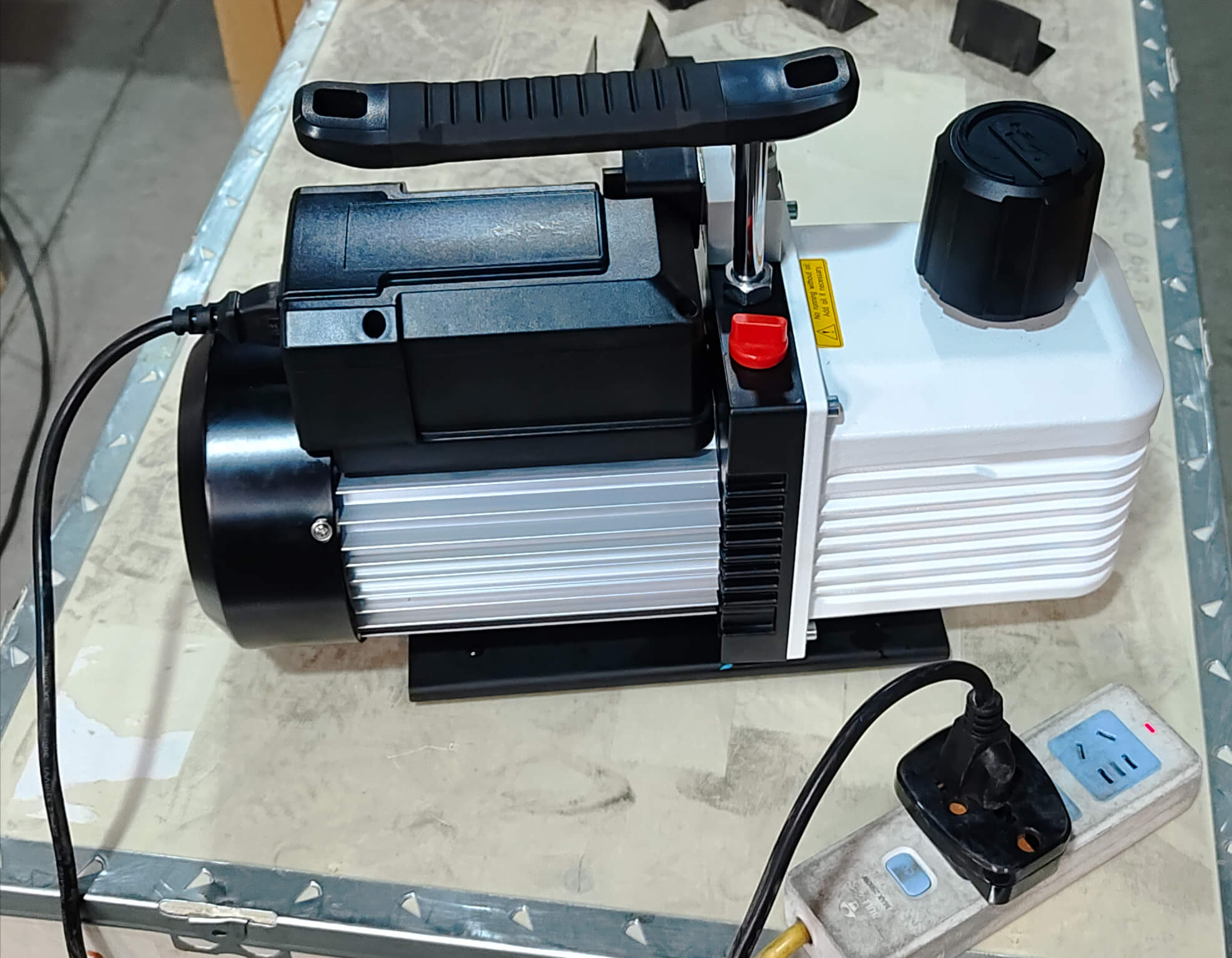

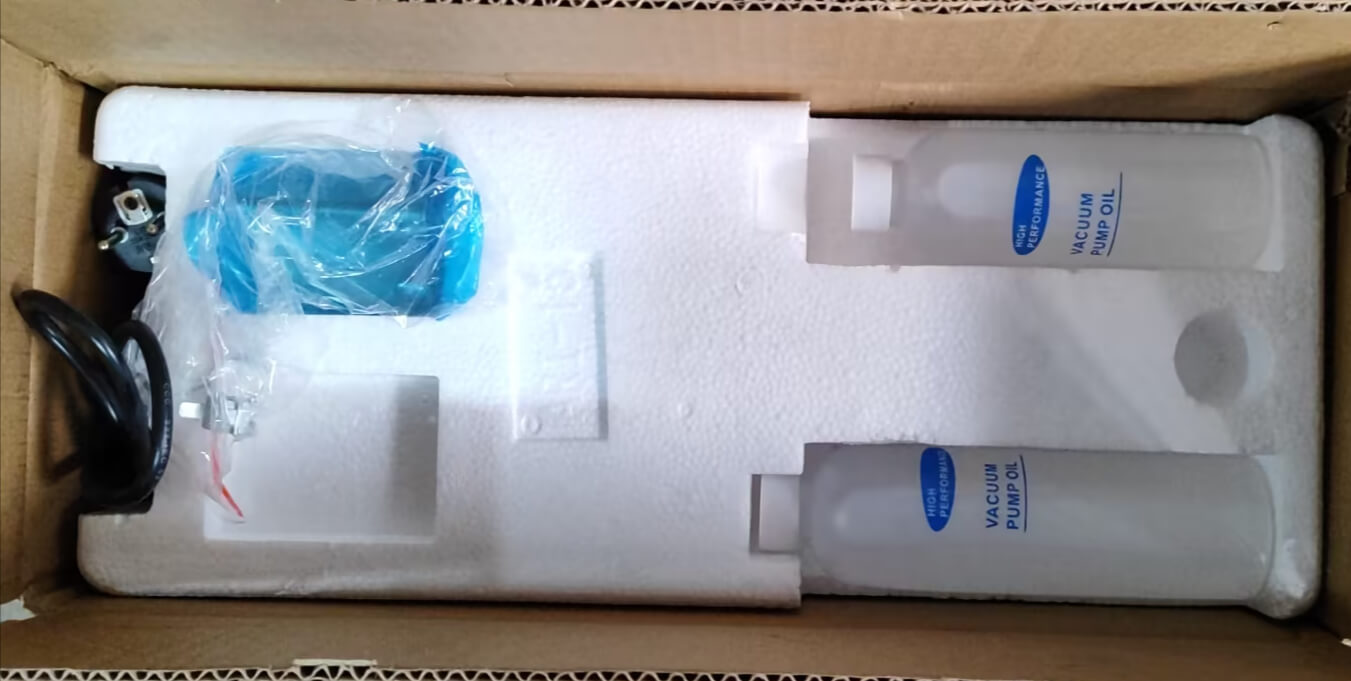

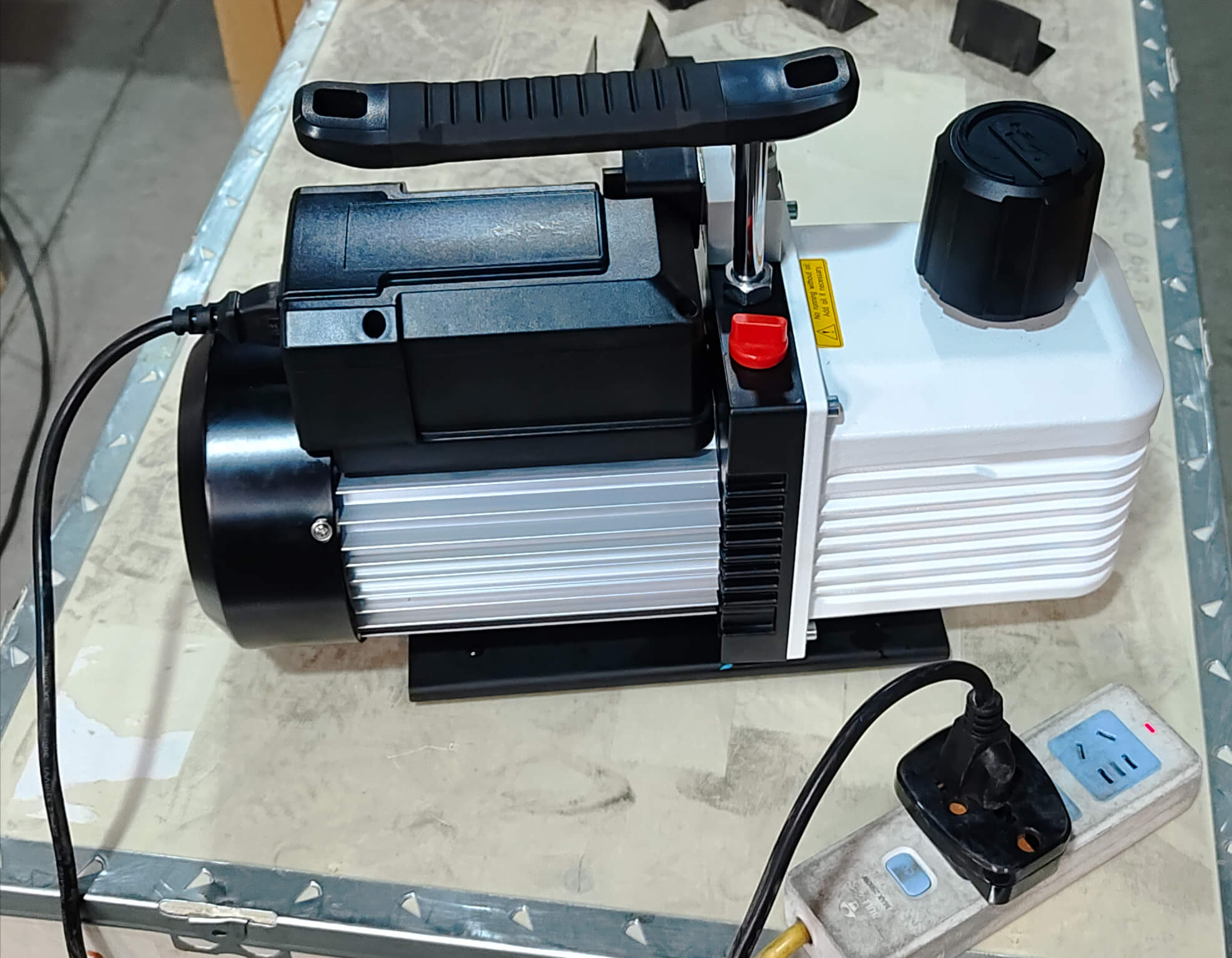

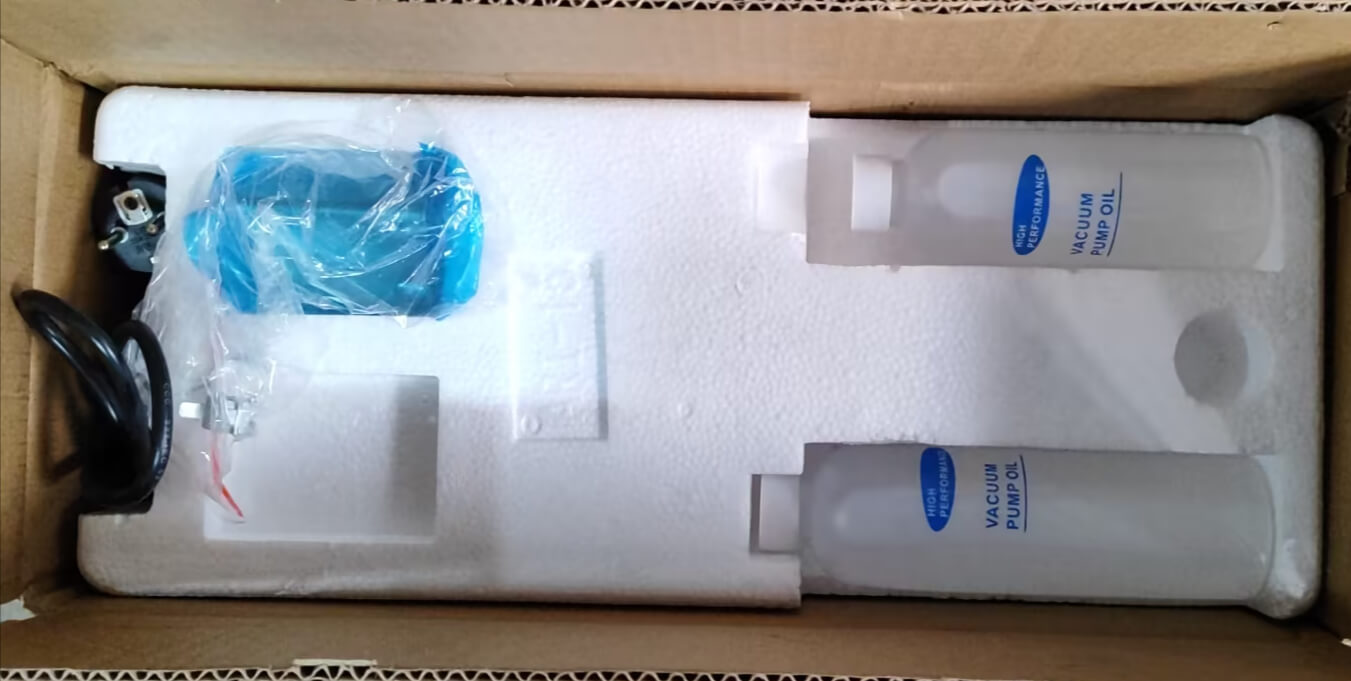

| Optional | Vacuum pump filter, silica gel connecting pipe, vacuum pump |

Vacuum Oven Features:

Intelligent PID control system with PT100 sensor and LCD controller.

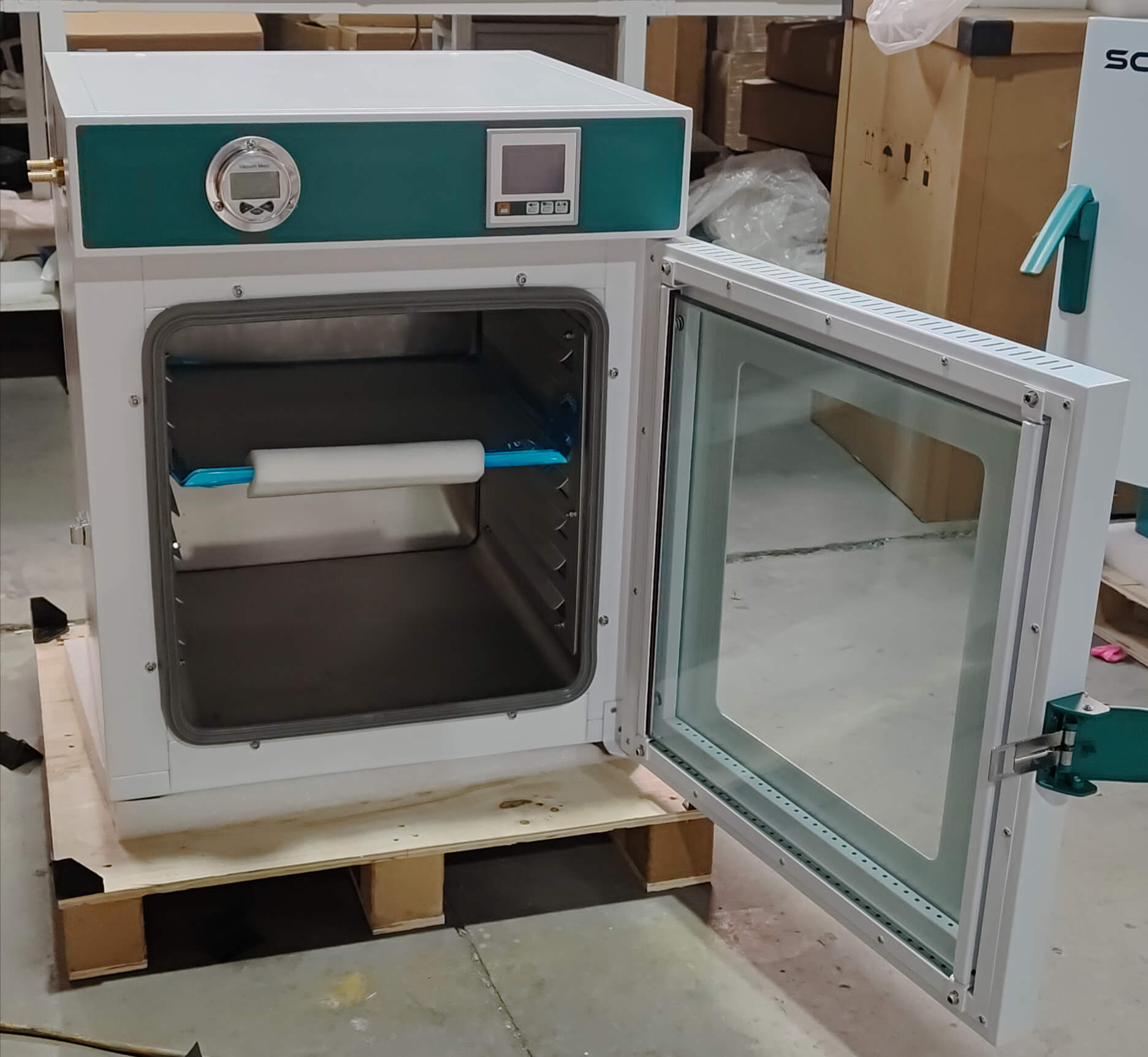

Double observation glass window, inner is explosion - proof glass, outside is resin protection plate, more safety.

With 4-side heating method with temperature conduction bracket for higher efficiency.

LCD vacuum gauge, accuracy class 0.5, Mpa, Kpa, bar, Psi, KGF/c㎡ five pressure units optional switch.

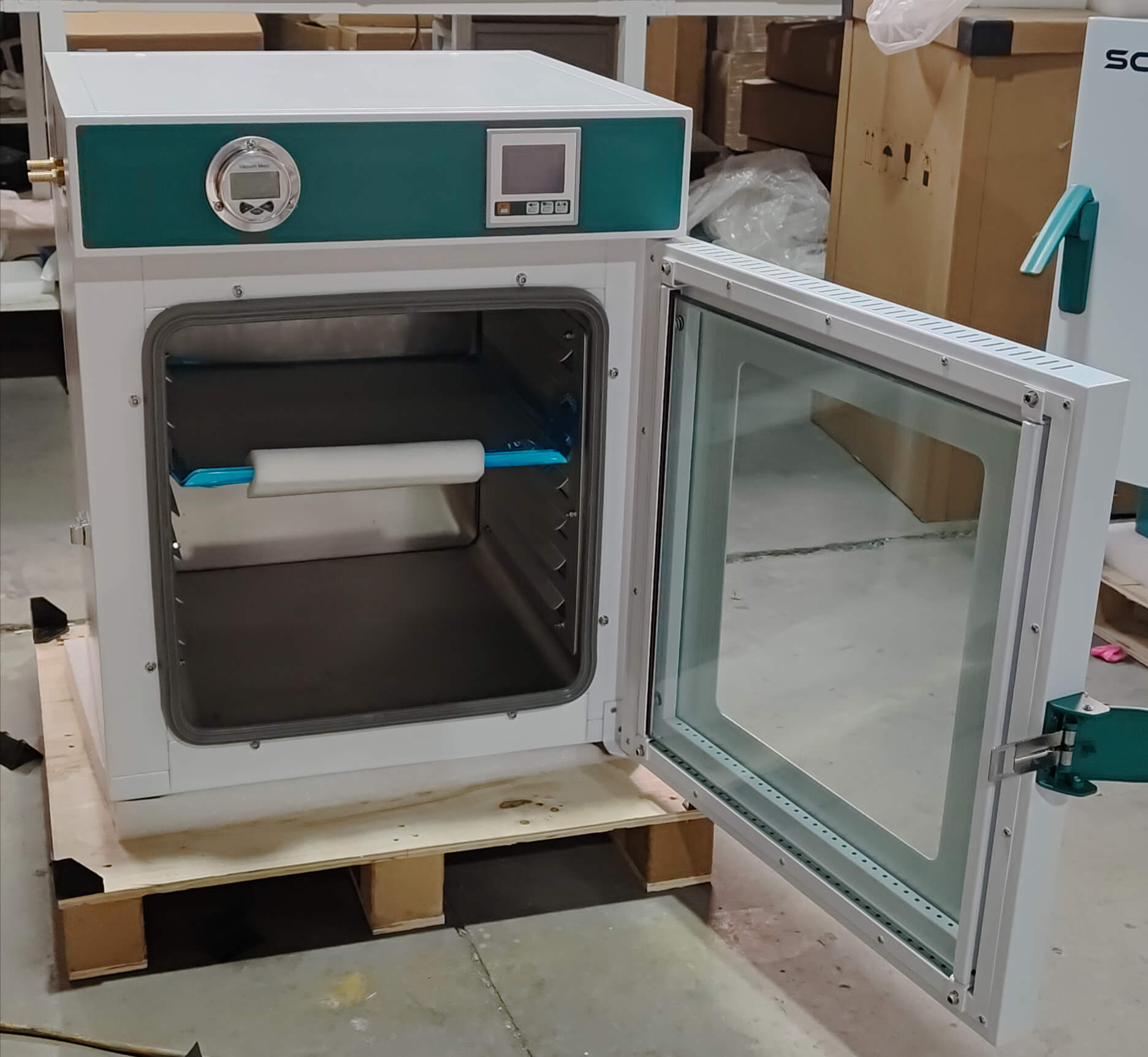

Details of Vacuum Oven (VO-90D):

The Vacuum Oven features a sleek, durable exterior with a clear digital control panel on the front. The display allows for precise temperature and vacuum level adjustments, providing ease of use for various drying, curing, or material testing applications. The compact and sturdy design ensures it fits seamlessly into laboratory or industrial environments.

Inside the Vacuum Oven, the chamber is designed for optimal airflow and uniform temperature distribution. The interior is spacious, made of high-quality stainless steel for easy cleaning and durability. The oven's adjustable shelves offer flexibility to accommodate different sample sizes, ensuring efficient processing under controlled vacuum conditions.

The Vacuum Oven is securely packaged in a sturdy box, with protective foam inserts that safeguard the device during shipping. The packaging is designed to minimize any risk of damage, ensuring the oven arrives in perfect condition. Clear labeling and detailed instructions are included for quick setup and use upon arrival.

English

English