Muffle Furnace Features:

Heating element options: Resistance wire, SIC heater, Mosi2 heater

Double layers forced air cooling structure, maintaining exterior temperature below 60°C

PID automatic control using SCR power control with phase angle fired and current limiting resistor

Programmable temperature-time curve with 30 segments

Temperature accuracy of ±1°C

Muffle Furnace Specifications:

| Model | MF-2-12T | MF-2-14T | MF-3-17T |

| Max. Temperature | 1200℃ for short time | 1400℃ for short time | 1700℃ for short time |

| Continuous Working Temperature | ≤1100℃ | ≤1300℃ | ≤1600℃ |

| Standard Heating Zone Length | 205mm | 205mm | 205mm |

| Standard Tube Diameter | φ40mm | φ40mm | φ40mm |

| Heating Element | Resistance wire | SIC heater | MoSi2 heater |

| Temperature Control | 30segments PID automatic control | 30segments PID automatic control | 30segments PID automatic control |

| Thermal Couple | K type | S type | B type |

| Thermal Couple | K type | S type | B type |

| Chamber Material | Alumina ceramic fiber | Alumina ceramic fiber | Alumina ceramic fiber |

| Heating Rate | 0~20℃/min (Suggestion 0~10℃/min) | 0~20℃/min (Suggestion 0~10℃/min) | 0~20℃/min (Suggestion 0~10℃/min) |

| Temperature Control Accuracy | ±1℃ |

| Temperature Uniformity | ±5℃ |

| Display Mode | LCD |

| Power Supply | AC110~450V, 50/60Hz |

| Max. Power | 2KW | 2KW | 3KW |

| Furnace Size (mm) | 40x205 | 40x205 | 40x205 |

Tube outer diameter can be customized: 40/60/80/100mm

Temperature zone length can be customized: 205/350/440mm Or customize as your requirement |

| Exterior Size (WxDxH)(mm) | 420x505x646 | 590x649x765 | 590x649x765 |

| Packing Size (WxLxH)(mm) | 640x550x870 | 740x730x1080 | 740x730x1080 |

| NW/GW (kg) | 60/73 | 90/103 | 140/158 |

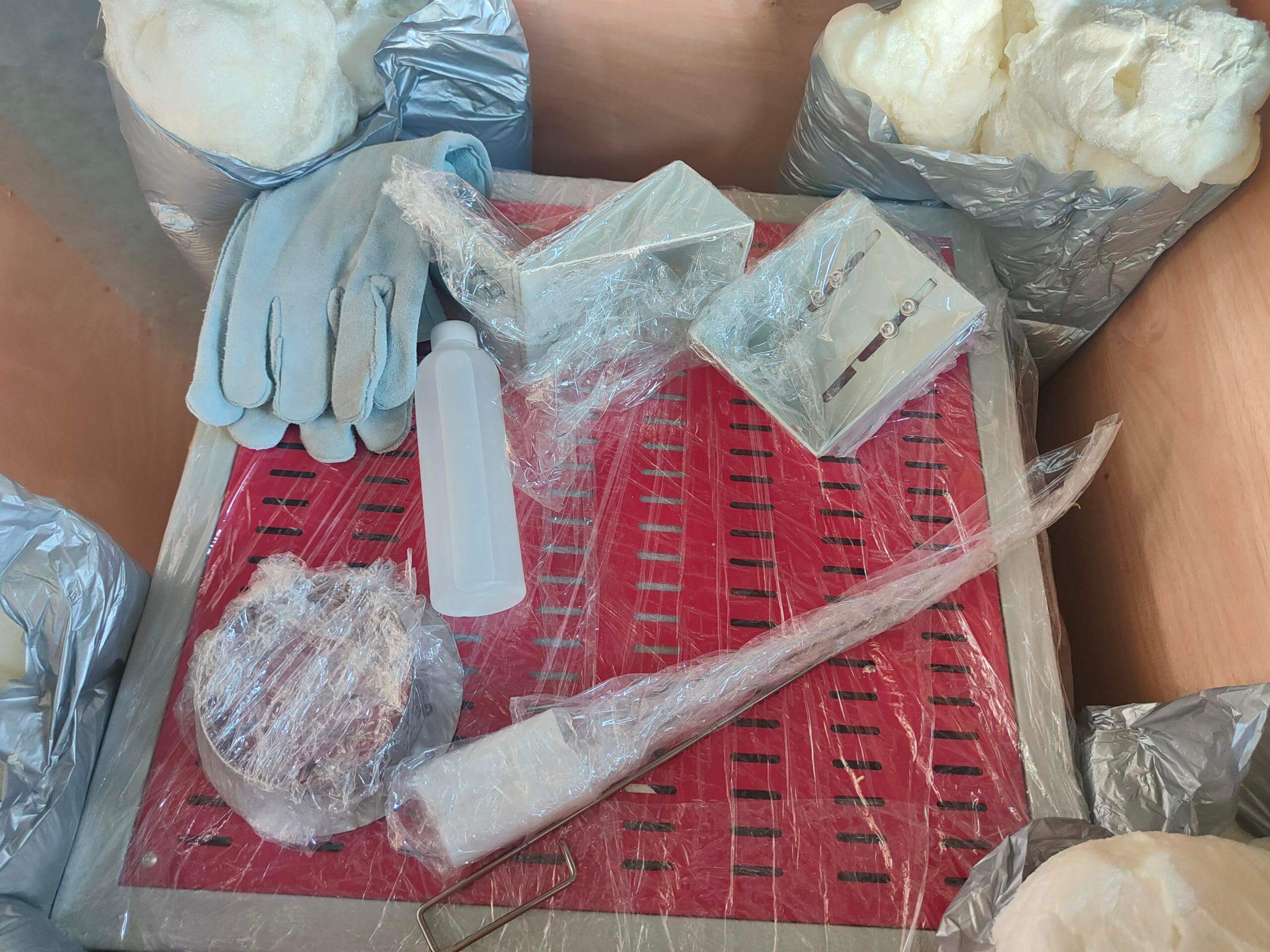

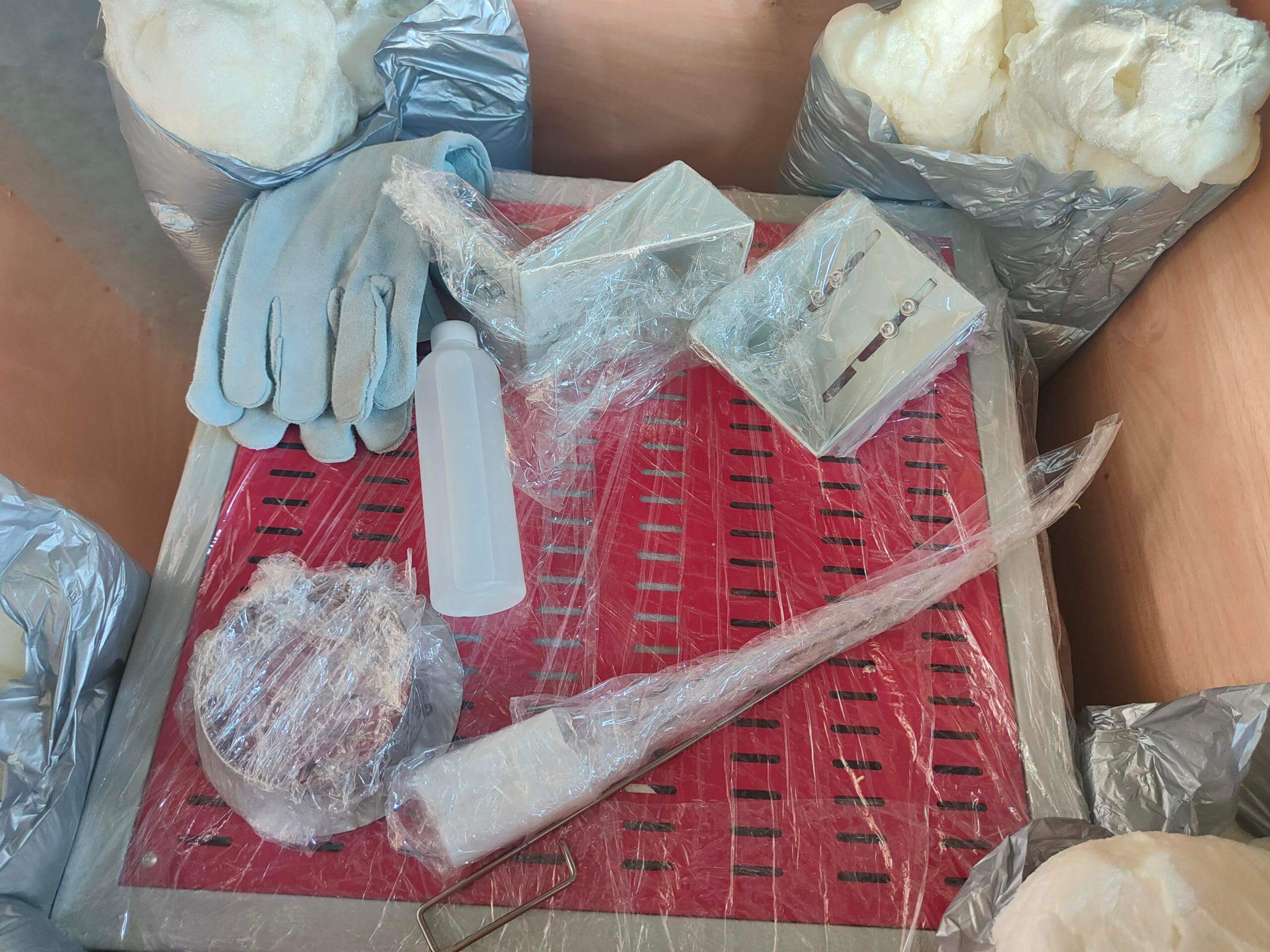

Details of Muffle Furnace(MF-2-14T):

The ceramic fiber structure inside the Ceramic Fiber Muffle Furnace highlights its excellent insulation and high temperature stability. The ceramic fiber material contributes to rapid heating and insulation while ensuring an even distribution of the internal temperature.

An external protective layer ensures safety during transportation. The red color of the logo design makes the unit's appearance more eye-catching and provides the necessary safety tips for operation.

English

English