Ceramic Fiber Muffle Furnace Features:

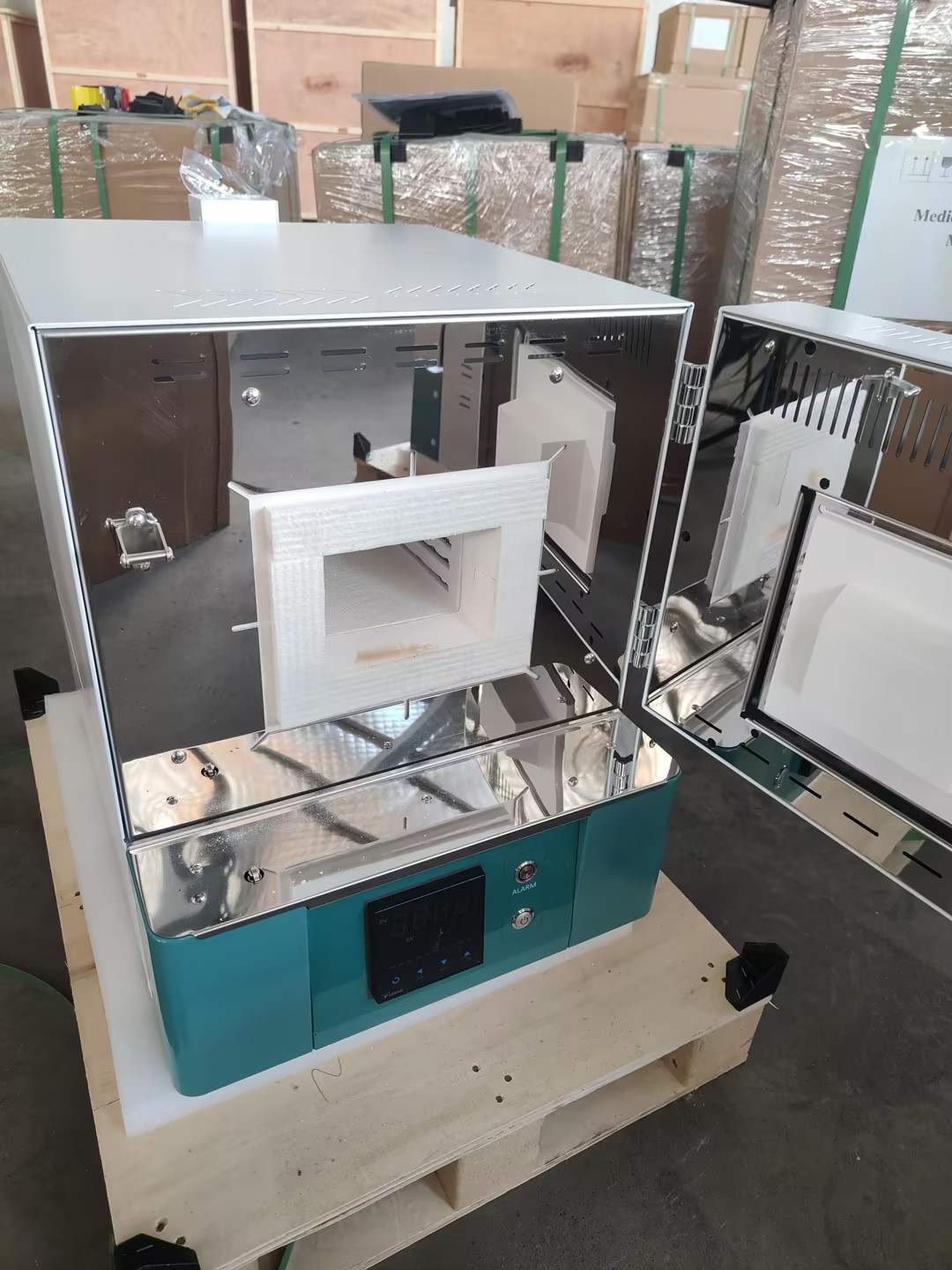

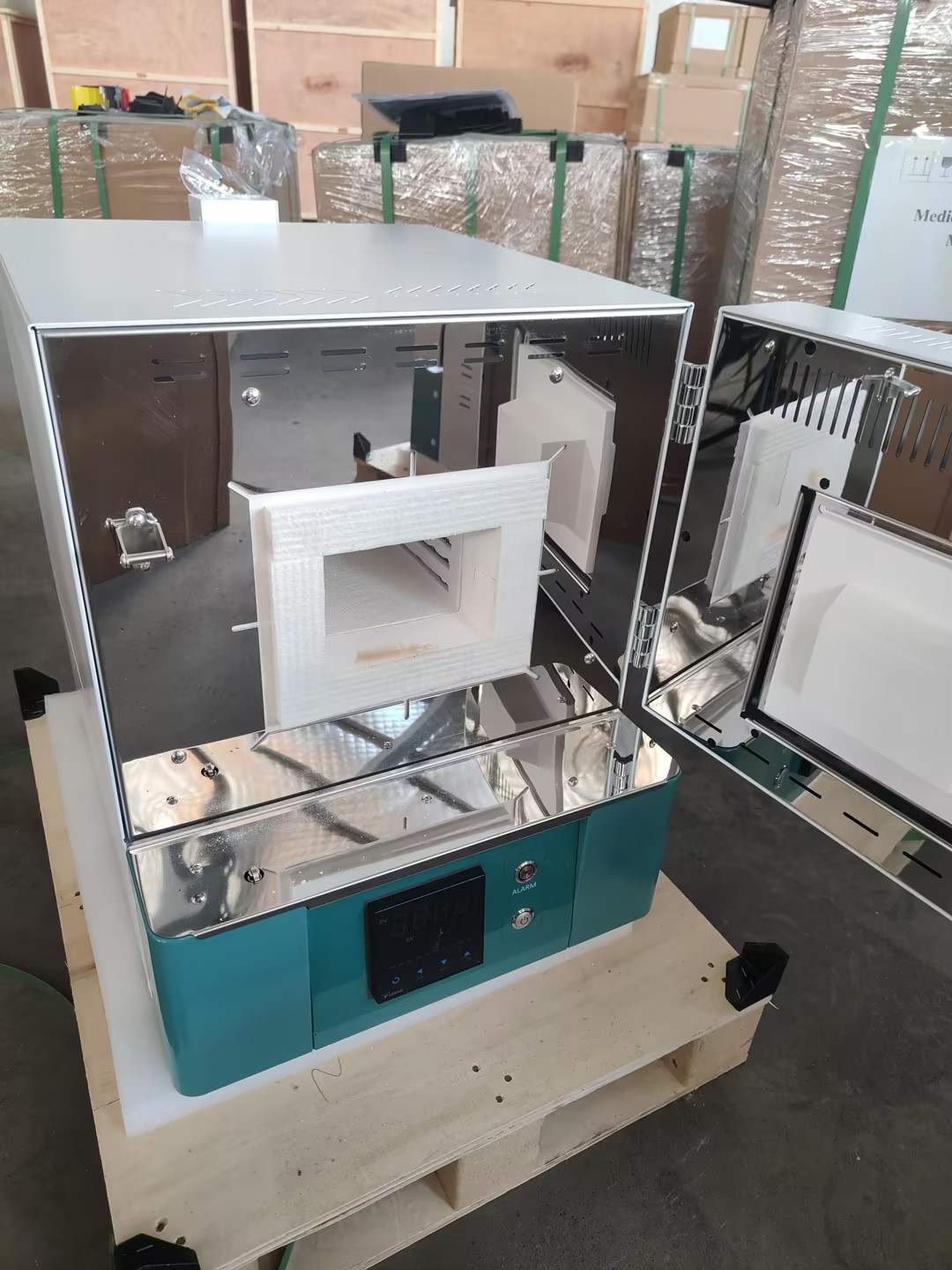

Features a mirror stainless steel mouth that maintains its color even after long-term use.

Equipped with an imported double insulated ceramic liner, ensuring stable performance.

Furnace is constructed with a vacuum-formed polycrystalline mullite fiber material, providing high-efficiency insulation.

The double-shell design incorporates an insulated air sleeve and double guiding air passage for enhanced thermal insulation.

It utilizes a high-precision micro-computer controller and precision sensor, resulting in accurate temperature control.

1200c Muffle Furnace Specification:

| Model | MF-2.5-12 | MF-5-12 | MF-8-12 | MF-10-12 |

| MF-2-12 | MF-7-12 | MF-12-12 | MF-16-12 |

| Heating Mode | Alloy wire heating in three sides left; right; top side. |

| Function | Temp. Range | 100-1200℃ |

| Temp. Resolution Ratio | 1℃ |

| Temp. Motion | ±1℃ |

| Temp.Rising Time to Max Temp | ≤30min |

| Structure | Chamber Material | Ceramic fiber |

| Outer Shell | Cold rolling steel electrostatic spraying exterior |

| Insulation Layer | Ceramic fiber |

| Heater | Alloy heating wire |

| Power Rating | 1.5KW | 3.0KW | 4.5KW | 6.0KW |

| Exhaust Hole | φ30mm(Chimney Size 80x60mm) |

| Controller | Temp. Control Mode | MF-2.5-12/MF-5-12/MF-8-12/MF-10-12: Domestic Xianmen Yudian single-stage temperature controller |

| MF-2-12/MF-7-12/MF-12-12/MF-16-12: Japaness conduction single-stage temperature controller |

| Temp. Setting Mode | Touch button setting |

| Temp. Display Mode | Measuring temperature: LED upper row, setting temperature: the lower row |

| Timer | No Timing Function |

| Operation Function | Fixed temperature operation, auto stop. |

| Additional Function | Sensor deviation correction, Temperature overshoot self-tuning, Internal parameter locked, Power-off parameter memory |

| Sensor | MF-2.5-12/MF-5-12/MF-8-12/MF-10-12: Platinum-rhodium sensor;

MF-2-12/MF-7-12/MF-12-12/MF-16-12: High precision K type sensor |

| Safety Device | Manual door security lock, over temperature sound-light alarm, door opening electrical outage, over-temperature protection, thermo couple failure |

| Specification | Inner Chamber Size(WxDxH)(mm) | 120x200x80 | 200x300x120 | 200x300x200 | 250x400x160 |

|

| Exterior Size (WxDxH)(mm) | 450x685x600 | 530x785x640 | 530x785x720 | 600x895x700 |

| Packing Size (WxLxH)(mm) | 780x580x750 | 660x875x770 | 660x875x850 | 730x985x830 |

| Volume | 2L | 7L | 12L | 16L |

| Current Rating (50/60Hz) | AC220V/6.6A | AC220V/13.6A | AC220V/20.4A | AC380V/9.9A |

| NW/GW (kg) | 33/59 | 45/50 | 62/68 | 77/96 |

| Optional Type | LCD program temperature control device with USB date storage |

| Model | MF-2P-12 | MF-7P-12 | MF-12P-12 | MF-16P-12 |

|

| Heating Mode | Alloy wire heating in three sides left; right; top side. |

| Function | Temp. Range | 100-1200℃ |

| Temp. Resolution Ratio | 1℃ |

| Temp. Motion | ±1℃ |

| Temp. Rising Time to Max Temp | ≤30min |

| Structure | Chamber Material | Ceramic fiber |

|

| Outer Shell | Cold rolling steel electrostatic spraying exterior |

| Insulation Layer | Ceramic fiber |

| Heater | Alloy heating wire |

| Power Rating | 1.5KW | 3.0KW | 4.5KW | 6.0KW |

| Exhaust Hole | φ30mm(Chimney size 80x60mm) |

| Controller | Temp. Control Mode | Japaness Fuji color LCD 64- segment programmed temperature controller |

| Temp. Setting Mode | Touch button setting |

| Temp. Display Mode | Measuring temperature: LED upper row, setting temperature: the lower row |

| Timer | Timing Function, 99 hours and 59 minutes (with Timing Waiting Function) |

| Operation Function | Fixed temperature operation, auto stop. |

| Additional Function | Sensor deviation correction, Temperature overshoot self-tuning, Internal parameter locked, Power-off parameter memory |

| Sensor | High precision K type sensor |

| Safety Device | Manual door security lock, over temperature sound-light alarm, door opening electrical outage, over-temperature protection, thermo couple failure |

| Specification | Inner Chamber Size (WxDxH) (mm) | 120x200x80 | 200x300x120 | 200x300x200 | 250x400x160 |

|

| Exterior Size (WxDxH)(mm) | 450x685x600 | 530x785x640 | 530x785x720 | 600x895x700 |

|

|

| Packing Size (WxLxH)(mm) | 580x775x730 | 660x875x770 | 660x875x850 | 730x985x830 |

| Volume | 2L | 7L | 12L | 16L |

| Current Rating (50/60Hz) | AC220V/6.6A | AC220V/13.6A | AC220V/20.4A | AC380V/9.9A |

| NW/GW (kg) | 33/37 | 45/50 | 62/68 | 77/96 |

| Optional Type | LCD program temperature control device with USB date storage |

Details of Ceramic Fiber Muffle Furnace:

This ceramic fiber muffle furnace has a clean look and features an easy-to-operate control panel with an intuitive digital display and operating buttons for conveniently adjusting temperature, time and other parameters.

The back is equipped with ventilation holes and a heat sink to ensure a stable temperature inside the furnace and good heat dissipation.

The furnace chamber is constructed with high temperature ceramic fibre material, which has excellent heat resistance and good insulation effect. The internal structure is well-designed and suitable for various heat treatment experiments and sample heating applications.

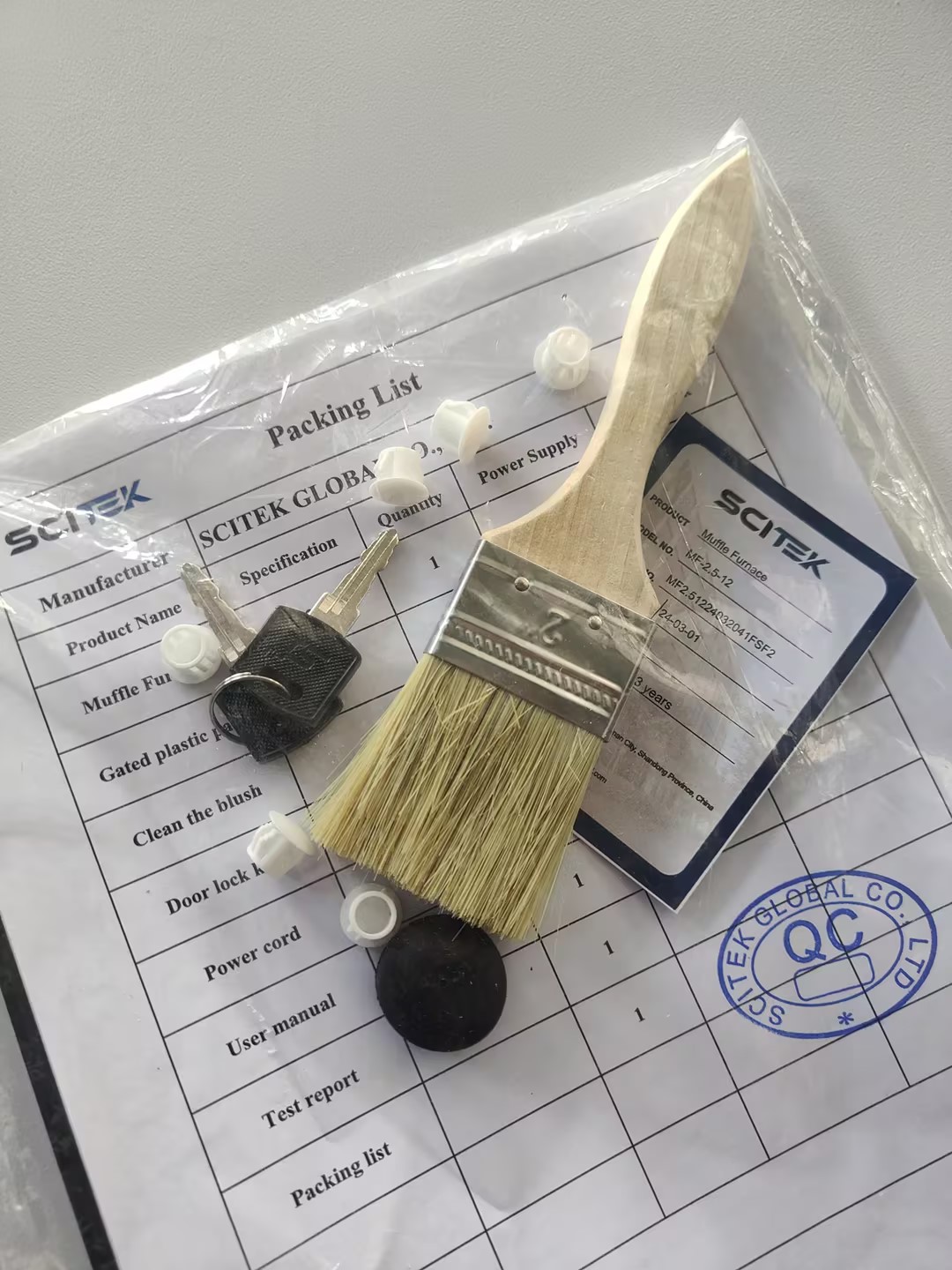

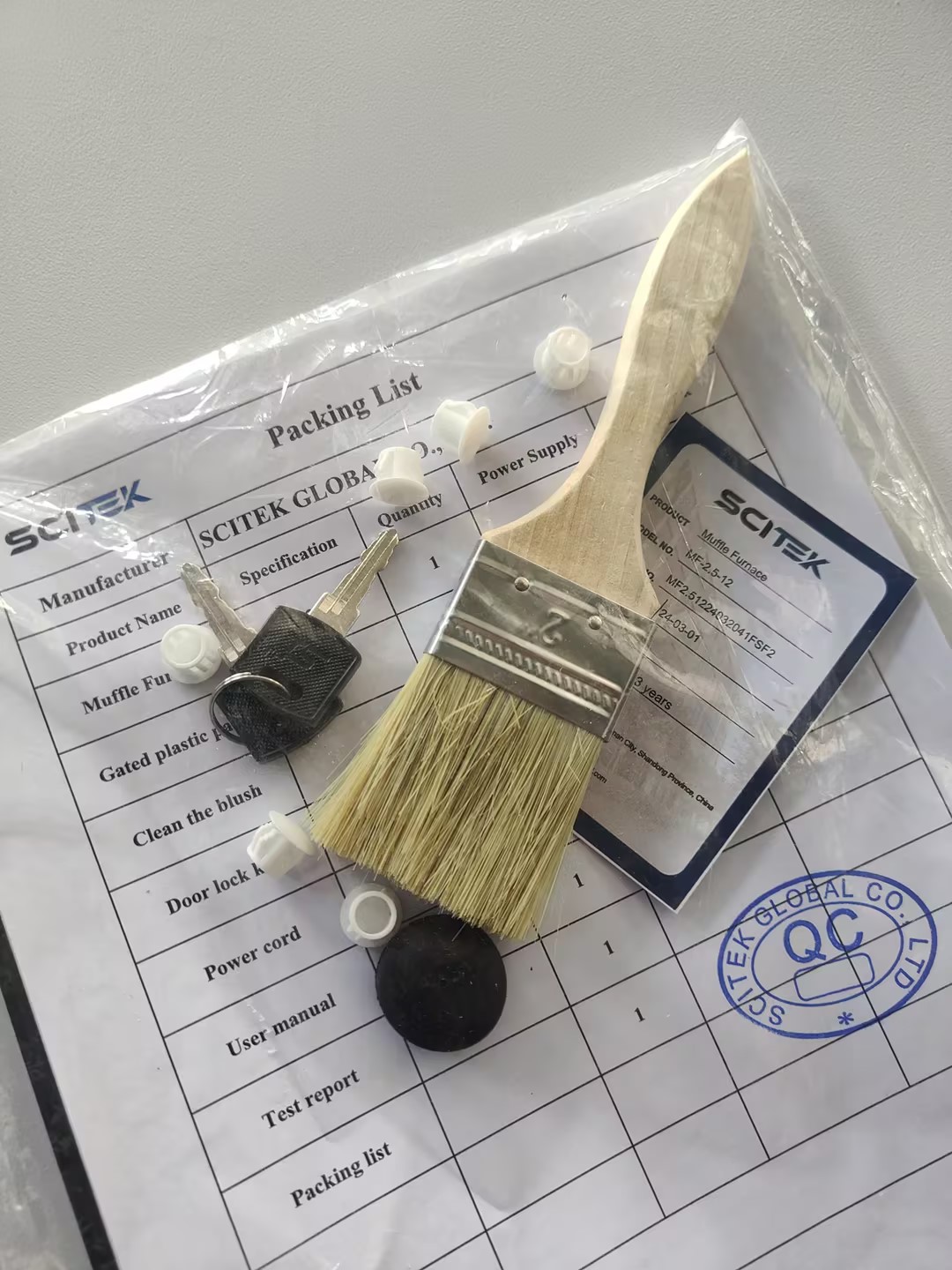

Ceramic Fiber Muffle Furnace Accessories

Ceramic Fiber Muffle Furnace Applications:

The ceramic fiber muffle furnace is a high-temperature furnace primarily used for high-temperature heating and heat treatment applications in laboratory and industrial environments. Applications include:

Sintering and heat treatment of materials

Sample drying and scorching

Heating and heat treatment in laboratory analysis and testing processes such as thermogravimetric analysis, elemental analysis, sample preparation, etc.

Catalyst activation

Sterilisation of medical devices

WHY SCITEK

36 months limited warranty

1-2 days handling and 7-30 days shipping

CE and FDA european standards

English

English