This box type furnace uses domestic high-quality resistance wire as the heating element, adopts a double-layer shell structure and 30 section programmed temperature control system, and the furnace is made of alumina polycrystalline fiber material.

The double layer furnace shell is equipped with an air cooling system, which can rapidly raise and lower the temperature, and has the functions of over temperature, coupling breaking, overcurrent protection, etc. The furnace has a temperature field balance.

It has the advantages of low surface temperature, fast temperature rise and fall, energy saving, etc. It is an ideal product for universities, research institutes, industrial and mining enterprises to do high-temperature sintering, metal annealing, and quality testing.

1200 Degree Muffle Furnace Specifications:

| Model | MF-2-12E |

| Max.Temp | 1200℃ (0-1100℃ Continuous working temperature) |

| Suggested Heating Rate | 10℃/min |

| Power | 220V, single-phases,1KW |

| Chamber Size(DxWxH)(mm) | 200x150x150 |

1200 Degree Muffle Furnace Feature:

Double layers forced air cooling structure,the temperature is less than 60℃.

Integrated compact design,stepped split joint structure,personalized furnace door and LED operation more convenient and practical.

Over-temperature protection,over-current overload protection,bias-temperature protection,burnout thermocouple warning, temperature setting ultra-high protection,temperature program ultafast protection.

Safety protection system: the furnace is equipped with a fuse and air switch. When the current exceeds the rated current of the air switch, the air switch will automatically open, effectively protecting the electric furnace.

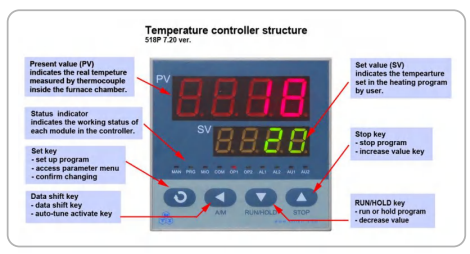

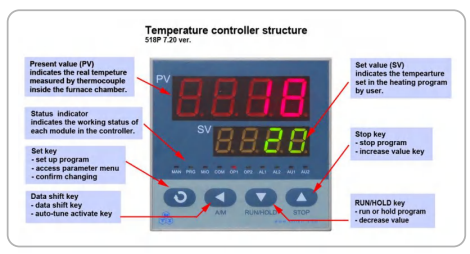

High precision temperature controller

3 sides heating furnace chamber

Heating element

Nickel chrome high-quality resistance wire (Kanthal A1 imported resistance wire can be selected)

Thermocouple

K type(overheating and couple breaking protection)

Temperature controlling

Temperature accuracy: ±1℃

Yudian programmed temperature control instrument (standard configuration)

30 segment program temperature control intelligent PID regulation.

With overtemperature protection and thermocouple breaking protection, the heating circuit of the electric furnace will be cut off automatically in case of overtemperature or thermocouple breaking (when the temperature of the electric furnace exceeds 1200 degrees or the thermocouple is burnt out, the AC relay on the main circuit will be cut off automatically, the main circuit will be cut off, the ON light on the panel will be off, the OFF light will be on, and the electric furnace will be protected limited)

It has power failure protection function, that is, when the furnace is powered on after power failure, the program does not start from the initial temperature, but from the furnace temperature when power failure occurs.

The instrument has the function of temperature self adjustment.

PID automatic control via SCR (silicon controlled rectifier) power control with phase angle fired, current limiting resistor.

Materials of furnace chamber

High quality high-purity alumina polycrystalline fiber solidified furnace formed by vacuum suction filtration.

Made with Japanese technology.

The spacing and pitch of resistance wires in the furnace are all arranged according to Japan's mature thermal technology, and the temperature field is simulated by thermal software

Three side heating (left, right and upper) is adopted to make the temperature field more balanced.

Packaging information

755x575x1025mm, 93KG

Warm Tips

For safety, please put the stove in a ventilated place.

In order to improve the service life of the furnace, we suggest that the heating rate should not exceed 10 ℃/min. The cooling rate shall not exceed 5 ℃/min.

The furnace is not vacuum sealed, and toxic or explosive gas is prohibited.

It is forbidden to put the materials directly on the furnace bottom cushion bricks. Please put the materials in the special crucible.

During heating, materials and crucibles shall not touch heating elements and thermocouples.

English

English