Gas chromatograph, also known as GC, is mainly used to separate and analyze mixtures within gases. In pharmaceuticals, petrochemicals, and environmental sciences, it can effectively help researchers analyze the complexity of chemical compounds. In this article, we will delve into its basic principles, mechanism of operation, applications, and malfunctions that the machine is prone to.

What is a Gas Chromatograph

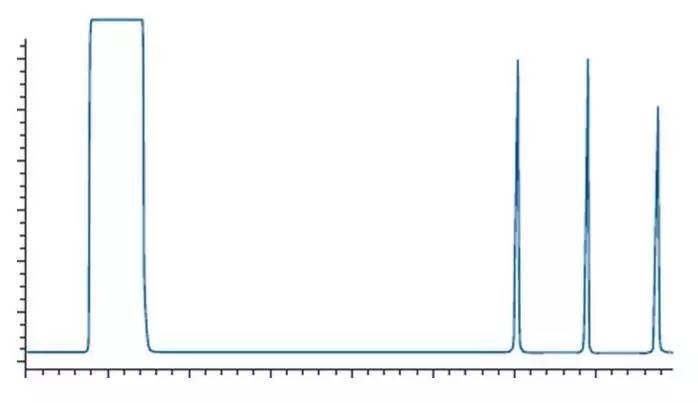

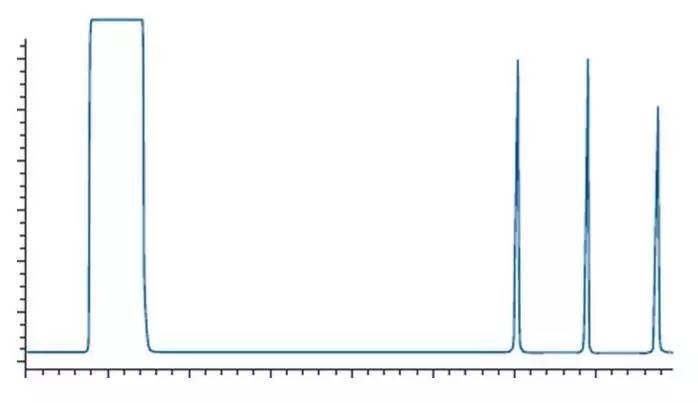

Chromatography using gas as the mobile phase is known as Gas Chromatography. It is an experimental technique commonly used to separate gas mixtures. Unlike physical separation techniques such as distillation, GC separates samples based on time differences. The sample passes through the chromatograph and produces a graph, a chromatogram. The position, size, and shape of the peaks in the chromatogram represent information about the sample's composition.

Working Principle of Gas Chromatograph

Gas chromatographs typically use helium, hydrogen and nitrogen as carrier gases to carry the sample entering the sample system into a column or packed column. Gas chromatography is divided into gas-solid chromatography (GSC) and gas-liquid chromatography (GLC) depending on the state of the stationary phase used:

GSC

"Gas" means that the mobile phase is a gas, and "solid" means that the stationary phase is a solid substance, such as activated carbon, silica gel, etc.

GLC

"Gas" means that the mobile phase is a gas and "liquid" means that the stationary phase is a liquid. For example, a layer of squalane coated with the inert material diatomaceous earth can separate and determine trace amounts of methane, acetylene, propylene, propane and other impurities in pure ethylene.

The components are separated in the column under the flushing of a carrier gas. They are then transferred to a temperature control system, which detects the components in sequence according to their chemical and physical properties.

The results of the detection and analysis are presented on the recorder using a chromatogram.

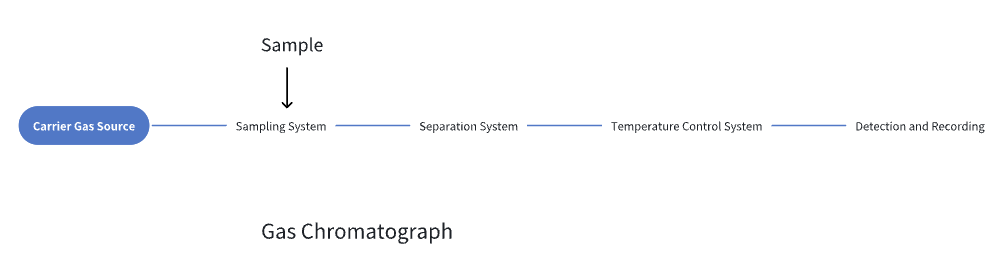

Components of a Gas Chromatograph

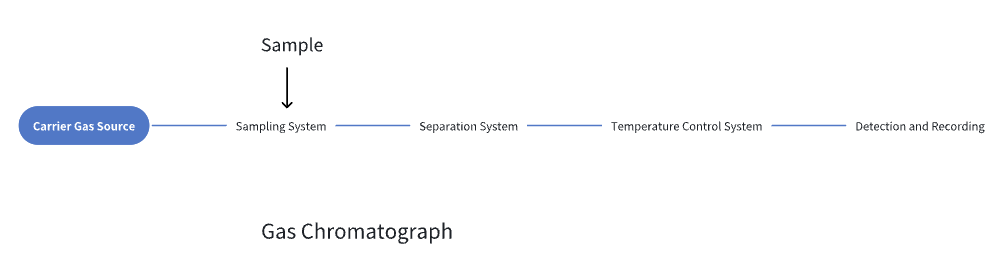

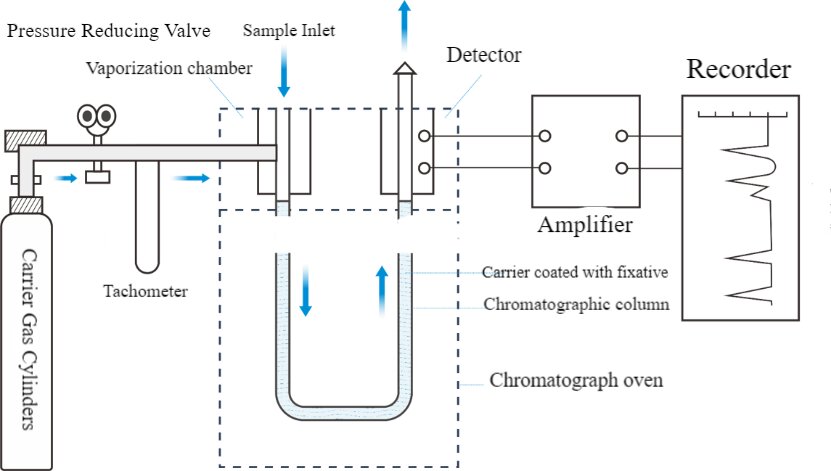

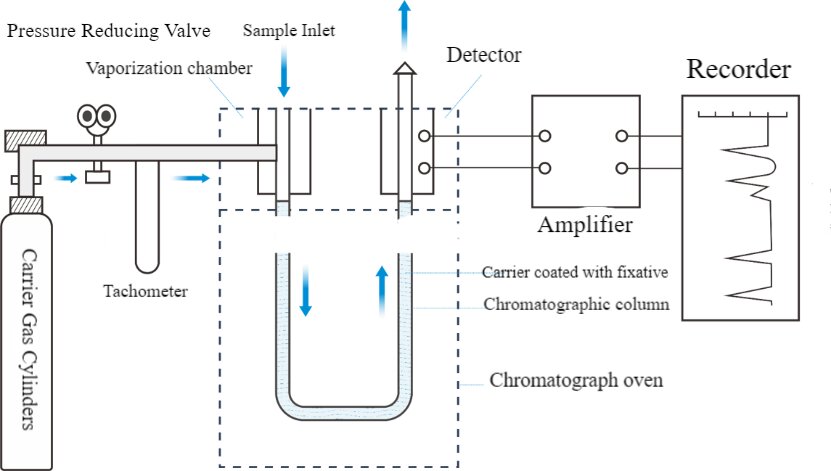

Carrier gas source: Includes the gas source, gas purification, gas flow rate control and measurement. This component is mainly for obtaining pure and stable flow rate carrier gas.

Sampling system: Including the injector and gasification chamber. The feeder is divided into two kinds: gas feeder and liquid feeder, and the gasification chamber is a device to gasify the liquid sample instantly.

Separation system: Including chromatographic column, column temperature box and temperature control device. According to the difference in distribution coefficient or adsorption coefficient of each component in mobile phase and stationary phase, the components are separated in the chromatographic column.

Temperature control system: Control the gasification chamber, column box and detector temperature.

Detection and Recording: Includes a detector, amplifier, recorder, or data processing device. Converts the concentration or mass of each component into an electrical signal and records it.

Carrier Gas Source

Pure carrier gas ensures accurate results; carrier gas with contaminants can react with the sample or column to produce false peaks, affecting the results. Common carrier gases used in gas chromatography are nitrogen, hydrogen, and helium. These three types of gases are chemically inert and do not react with the stationary solution or the analyte.

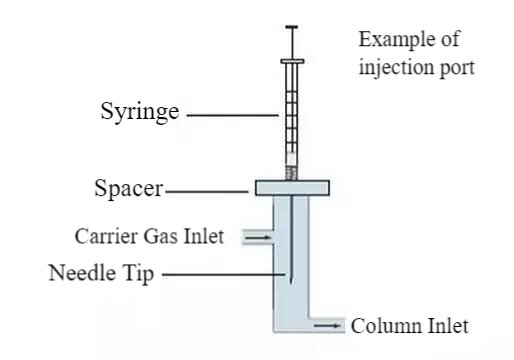

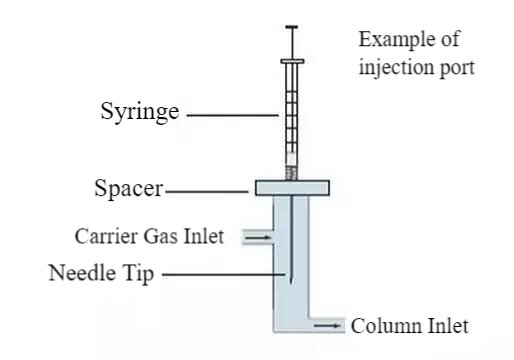

Sample Inlet

The volatilized sample is introduced into the carrier gas stream in the injection port. The most commonly used inlet devices are injection inlets and inlet valves.

Syringes are suitable for injecting small amounts of gas and liquid samples.

Inlet valves are suitable for automated operations and large sample volumes and are usually connected to the inlet port.

* Where the accuracy of the control of the gas flow rate and flow rate affects the stability of the gas chromatography. A purifier should be fitted to each GC if a gas generator is used instead of a gas cylinder. And keep the gas source as close as possible to the back of the instrument.

Chromatographic Columns

The separation of the samples takes place in the column and most of the separations are strongly dependent on temperature. Therefore, the columns should be installed in a chamber for precise temperature control.

Chromatographic column type:

| Type | Material | Feature |

| Filled Columns | Copper, aluminium, stainless steel, quartz, nylon, tetrafluoroethylene and polyesters | Suitable for quantitative analysis of routine samples, especially high purity samples |

| Capillary Columns | Flexible quartz | Suitable for separating complex or trace samples and for residue analysis. Much higher separation efficiency than packed columns |

| Preparation Columns | Copper, aluminium, stainless steel, quartz, nylon, tetrafluoroethylene and polyester | Suitable for analyses requiring higher separation capacity or more complex samples |

Detector

The carrier gas stream from the column containing the separated components passes through the detector and generates a signal. The output signal from the detector is converted into a chromatogram.

There are several types of detectors to choose from, but all of them have the same function:

To produce a stable electrical signal (baseline) when no component to be separated is flowing through the detector;

Produce a different electrical signal (baseline) when the component to be separated flows through the detector.

The chromatogram records the electrical signal output from the detector.

It can be processed in several ways:

Recording on a strip chart recorder, processing using a digital integrator, and processing with a computer data system.

Temperature Control System

In gas chromatography, temperature control is extremely important, and it directly affects the column's separation efficiency and the detector's sensitivity and stability.

The main objects of the temperature control system are the vaporization chamber, the column and the detector.

In the vaporization chamber, it is necessary to ensure that the liquid sample is instantly and completely vaporized. In the column box, it is necessary to ensure complete separation of components. When there are many kinds of components to be measured in the sample, the temperature of the column box needs to be controlled by the program to change the temperature. The components should be separated at the optimum temperature and ensure no condensation occurs as the components pass through the detector.

The temperature control method is divided into constant temperature and programmed temperature increase.

Constant temperature: general gas analysis and simple liquid sample analysis can be used in constant temperature mode

Programmed temperature increase: the so-called programmed temperature increase refers to the linear or non-linear change of the column temperature from low to high temperature over time in an analysis cycle. The components with different boiling points will flow out at their optimal column temperatures, thus improving the separation effect and shortening the analysis time. A programmed warming method should be used if it is difficult to achieve a good separation at a constant temperature.

Operating Procedure of Gas Chromatography

Use steps

Turn on the regulated power supply.

Open the nitrogen and carrier gas switching valves, then check whether there is any air leakage to ensure good air tightness.

Adjust the total flow rate to the appropriate value (measured according to the graduated flow meter).

Open the air and hydrogen switch valve and adjust the air and hydrogen flow rate to the appropriate value.

Open the computer and workstation.

FID detector temperature reaches 150 ℃ or more. Press the FIRE key to ignite the FID detector flame.

Set the FID detector sensitivity and output signal attenuation.

To be set up when the parameters reach the settings, you can enter the sample analysis.

After the experiment is finished, turn off the hydrogen and air first, and use nitrogen to blow the column clean and then turn off the machine.

Note:

The total pressure gauge of the gas cylinder shall not be lower than 2Mpa;

Must be strictly leak detection;

Opening the power supply when there is no carrier gas pressure is strictly prohibited.

Application of gas chromatography

Gas chromatography is a chromatographic analysis method with gas as the mobile phase, which is mainly used to separate and analyse volatile substances. It is widely used in the fields of medicine and health, petrochemical industry, environmental monitoring, biochemistry and so on.

Routine Maintenance

In order to ensure that the gas chromatograph can operate normally, it is necessary to carry out regular maintenance.

*Maintenance period: The maintenance period of gas chromatograph is generally set at 3 months. In practice, the maintenance cycle can be extended or shortened according to the workload and operation of the instrument.

Carrier gas source: Check whether the generator or gas cylinder is in normal condition, dewatering filter, activated carbon and deoxygenation filter, and replace the packing regularly.

Leakage of pipeline: You can check whether the pipeline leaks by dropping soap suds into the connection. If bubbles appear, it is a leak.

Detector maintenance: Detector components such as the collector, receiver tower, flame nozzle, base, column nut, etc., must be cleaned with acetone solution after use. Generally ultrasonic 2 hours until clean, after cleaning and drying spare.

Maintenance of the column temperature box: The shell of the column temperature box and the interval volume can be degreased cotton dipped in ethanol scrub.

FAQ

What does retention time mean?

The time from the start of the injection to the maximum value of each component of the efflux curve can be used to indicate the position of the chromatographic peaks, which is called the retention time and is expressed as t.

What is a chromatogram?

A chromatogram is a graph of the response signal time or carrier gas outflow volume generated when the column effluent passes through the detector system after injection.

What is a chromatographic peak? Peak area?

The column effluent components through the detector system when the response signal generated by the differential curve is called chromatographic peak.

Out of the peak to the peak back to the baseline surrounded by the area, known as the peak area.

How to measure the carrier gas flow rate?

High-grade chromatographs are equipped with automatic testing devices. No automatic test device can be used to measure the soap film flowmeter, the soap film flowmeter connected to the test outlet, and the flow rate per minute.

How to control the carrier gas flow rate?

Carrier gas flow rate control mainly relies on the pressure-reducing valve on the high-pressure cylinder on the gas line to reduce pressure, and then by the instrument's pressure regulator valve to stabilize the pressure, and then by the flow regulator valve to achieve stable control of the carrier gas flow rate. The pressure the pressure-reducing valve gives should be higher than the pressure after stabilization.

*Non-programmed warming chromatography generally does not have a flow regulator valve and can only rely on the pressure regulator valve to control the flow rate.

How to choose the best operating conditions for carrier gas flow rate?

In chromatography, the optimum carrier gas flow rate can be selected to obtain the minimum value of plate height. Therefore, the optimal flow rate value can be found from the rate theory formula about peak expansion. Typically, the internal diameter of the column is 4 mm and the available flow rate is 30 ml/min.

How to choose the best operating conditions for the gasification chamber temperature?

The temperature of the gasification chamber should be controlled so that the sample can be gasified instantly without causing decomposition of the sample.

General rule is that the temperature of the gasification chamber is higher than the boiling temperature of the sample and the peak height can be used for quantification if the gasification temperature is kept constant.

Chromatographic analysis, gas, liquid, solid samples with what injector injection?

Gas sample injection: syringe injection; gas quantitative tube injection, commonly used six-way valve.

Liquid sample injection: micro syringe.

Solid sample injection: solid samples are dissolved and injected with a micro syringe, headspace injection method.

How to choose the best operating conditions for column temperature?

Generally use the column temperature for the average boiling point of the sample around or a little lower;

Column temperature should not be higher than the maximum use temperature of the stationary solution and lower than the decomposition temperature of the sample;

The column temperature can also be much lower than the column temperature under special circumstances.

English

English