Lab Point Freeze Dryer Specifications:

| Model | FD-20S | FD-20T | FD-30S | FD-30T | FD-50S | FD-50T | FD-100S | FD-100T |

| Type | Standard | Top-press | Standard | Top-press | Standard | Top-press | Standard | Top-press |

| Freeze Drying Area (m2) | 0.24 | 0.24 | 0.36 | 0.36 | 0.5 | 0.5 | 1 | 1 |

| Shelf Temperature (℃) | -50~+70 | -50~+70 | -50~+70 | -50~+70 | -50~+70 | -50~+70 | -50~+70 | -50~+70 |

Condenser Temperature

(no-loading) (℃) | ≤-80 | ≤-80 | ≤-80 | ≤-80 | ≤-80 | ≤-80 | ≤-80 | ≤-80 |

| Vacuum Degree (no-loading) (Pa) | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| Condenser Capacity (L) | 13 | 13 | 13 | 13 | 17 | 17 | 35 | 35 |

| Ice Condenser Capacity(kg/24h) | 6.5 | 6.5 | 6.5 | 6.5 | 10 | 10 | 15 | 15 |

| Tray(Qty) | 2+1 | 2+1 | 3+1 | 3+1 | 4+1 | 4+1 | 4+1 | 4+1 |

| Tray Size (LxWxD)(mm) | 300x400 x13 | 300x400 x13 | 300x400 x13 | 300x400 x13 | 300x400 x13 | 300x400 x13 | 550x480 x13 | 550x480 x13 |

| Height Between Trays(mm) | 145 | 145 | 90 | 90 | 90 | 90 | 90 | 90 |

| Total Loading Capacity (L) | 4.5 | 4.5 | 7 | 7 | 10 | 10 | 20 | 20 |

| Temperature Uniformity(Tray) (℃) | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 | ±1 |

| Refrigerant | CFC-free | CFC-free | CFC-free | CFC-free | CFC-free | CFC-free | CFC-free | CFC-free |

| Electric Defrosting | Y | Y | Y | Y | Y | Y | Y | Y |

| Stoppering Mode | / | Automatic hydraulic | / | Automatic hydraulic | / | Automatic hydraulic | / | Automatic hydraulic |

| Total Qty. Of Vial Φ22 | 468 | 468 | 702 | 702 | 1040 | 1040 | 2016 | 2016 |

| Total Qty. Of Vial Φ16 | 864 | 864 | 1296 | 1296 | 1944 | 1944 | 3944 | 3944 |

| Total Qty. Of Vial Φ12 | 1584 | 1584 | 2376 | 2376 | 3456 | 3456 | 7020 | 7020 |

| Consumption (kW) | 3.5 | 4.5 | 3.5 | 4.5 | 6.5 | 7.5 | 9.5 | 10.5 |

| Electricity | AC380V/50Hz(standard), other electricity type can be customized |

| External Size (WxDxH)(mm) | 1339x932x1319 | 1339x932 x1601 | 1339x932 x1319 | 1339x932 x1601 | 1337x1015x1454 | 1337x1015x1754 | 1633x1027x1612 | 1633x1027x1912 |

| Shipping Size (WxDxH) (mm) | Main Body | 1490x114 0x1660 | 1490x1140 x1960 | 1490x1140 x1660 | 1490x1140 x1960 | 1660x1260x1710 | 1660x1260x2060 | 1960x1340x1860 | 1960x1340x2210 |

| Vacuum Pump | 850x330x450 | 850x330x450 | 850x330x450 | 850x330x450 | 850x330x450 | 850x330x450 | 1010x340x510 | 1010x340x510 |

| Gross Weight (kg) | 550 | 600 | 580 | 630 | 690 | 740 | 900 | 950 |

Optional:

Optional eutectic point test function, convenient for users to better explore the freeze-drying process

Lab Freeze Dryer Features:

7-inch touchable panel displays digital and curve data for sample's temperature, condenser temperature, and vacuum valve.

Touch panel is designed with ergonomics in mind, providing comfortable operation.

Standard USB interface, data can be exported conveniently for user information management.

Large-volume stainless steel condenser without coils enables independent sample pre-freezing.

Rack temperature can be adjusted and controlled to aid in freeze-drying technology research.

The condenser and drying chamber are separately designed for high moisture capture and fast dry time.

Freeze dryer has two working modes, manual and automatic, are available with 40 programs in the automatic operation program, each with 40 temperature control sections to meet various freeze-drying processes.

User level and password can be set for decentralized operation and management.

The equipment can save hundreds of process recipes with each group containing 40 temperature control sections to improve process optimization rate.

Reliability:

In-situ freeze-drying design, avoid the contamination during material transfer;

High performance compressor, cascade system, high cooling efficiency and fast cooling speed.

The rack is cooled and heated by silicone oil for more uniform temperature and 1°C accuracy.

Condenser and operation panel are made by stainless steel.

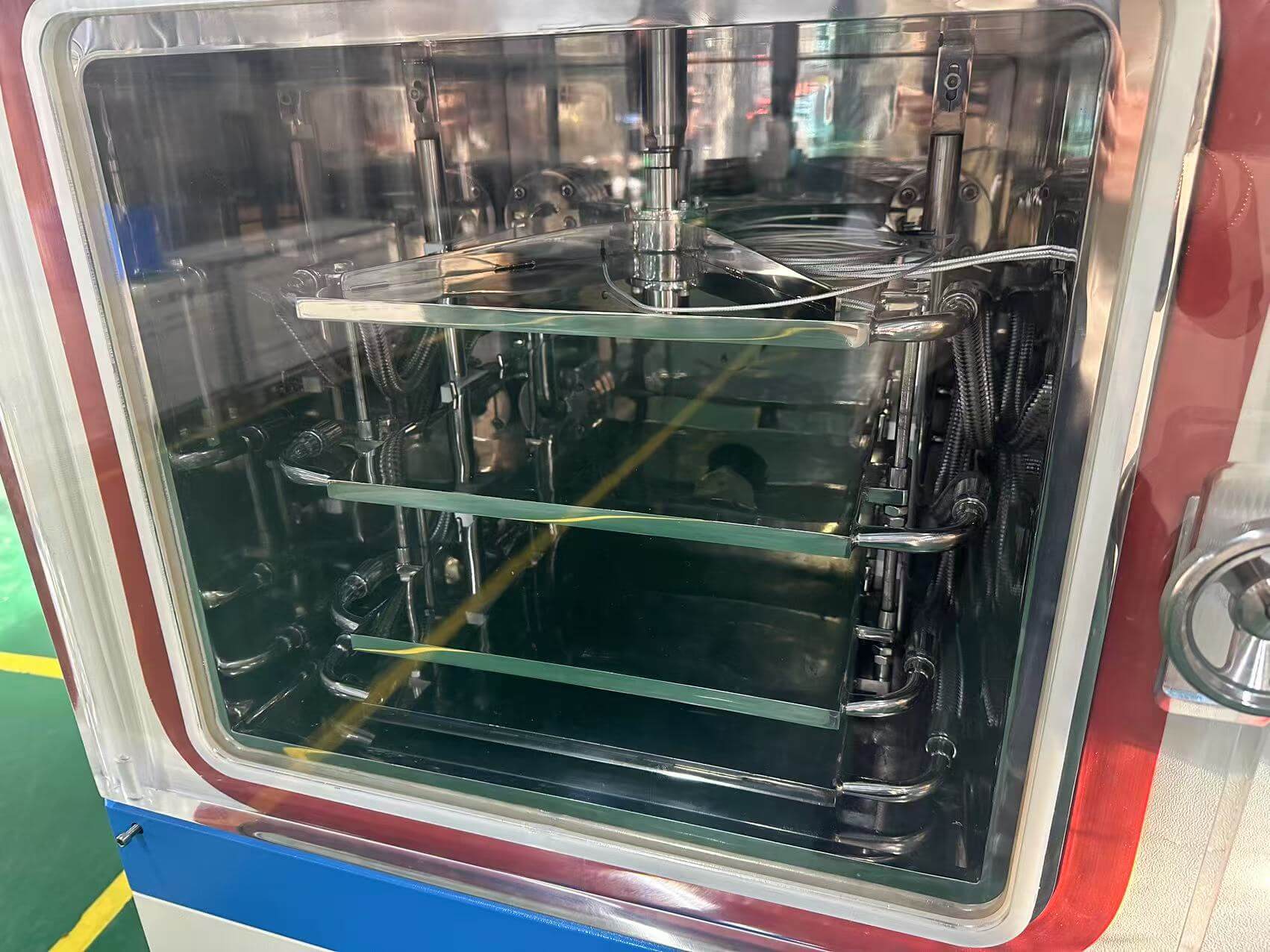

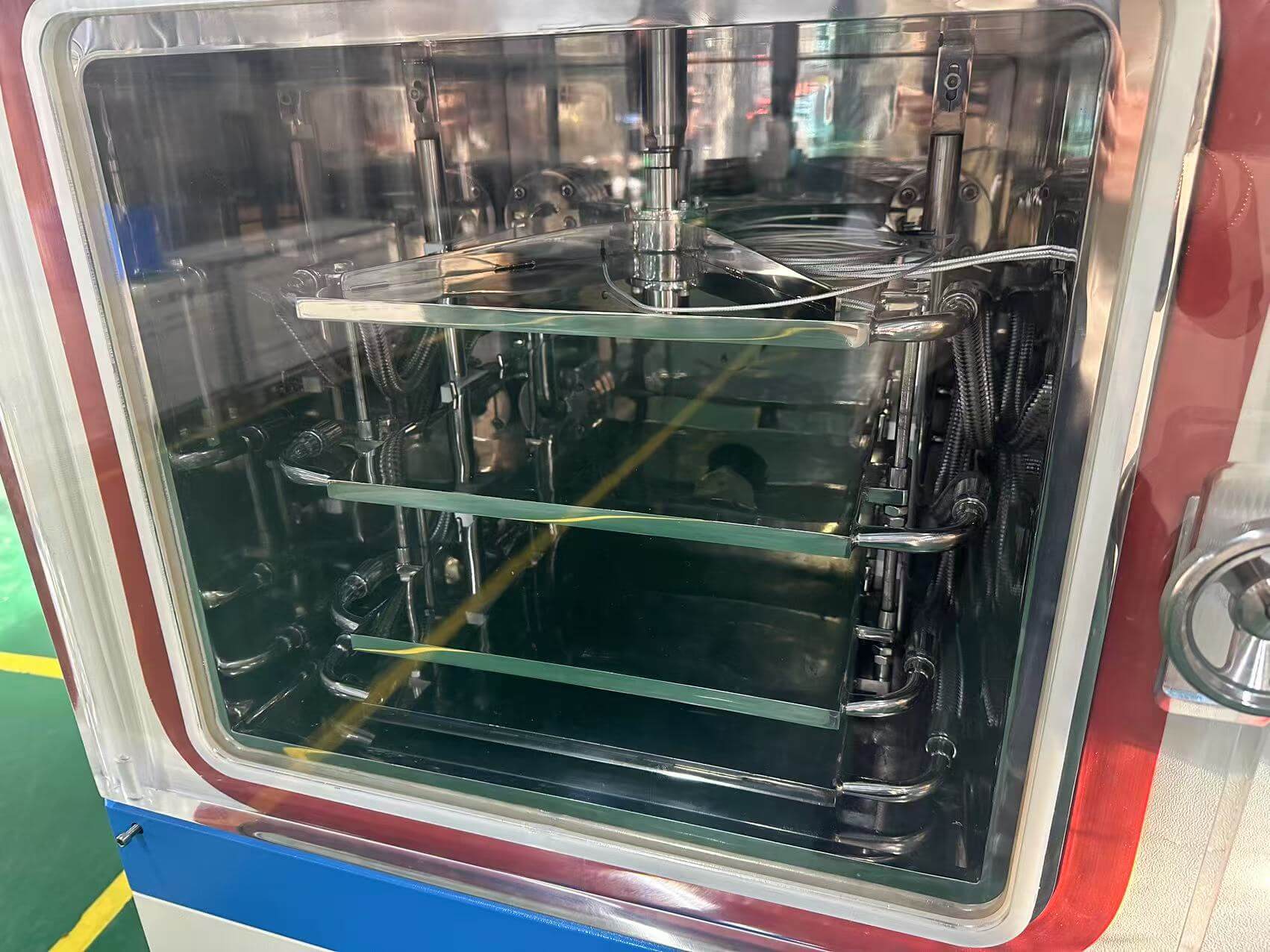

High transparent organic glass in drying chamber helps users to observe materials changes.

Pirani vacuum gauge is used to ensure stable freeze-drying performance

Automatic defrost function.

Point Freeze Dryer Display (FD-30T):

The mainframe is equipped with transparent door and window, clear operation interface, supporting vacuum gauge and digital display screen integrated integration, convenient for users to monitor the real-time operation status. Clean appearance, modern design, reflecting the style of high-end experimental equipment.

The shelves are clearly distributed and equipped with pallet trays for high space utilization. Multi-layer structure is designed to meet the lyophilization needs of different samples, and at the same time, it is easy to observe and operate.

The body adopts high-strength metal shell, reasonable distribution of heat dissipation holes, which is conducive to the stable operation of the equipment and the rapid release of heat.

The internal display of the accessories box, vacuum hose, power cord, connecting line and other accessories are complete and neatly arranged, independent packaging to ensure safe transportation. All auxiliary components are original configuration, easy for users to quickly install and debug the use.

The whole machine is packed and wrapped tightly with protective film to prevent dust and scratches and to ensure that freeze dryer is not damaged during transportation. Transparent film can be clearly seen under the host panel and chamber door, easy to quickly confirm the receipt of the equipment type and integrity.

English

English