Laboratory glassware washers can effectively clean a wide range of glassware, including beakers, flasks, test tubes, pipettes, burettes, and more. They can remove residues, contaminants, and other substances that may affect the accuracy and reliability of laboratory experiments.

Advantage of Lab Glassware Washer:

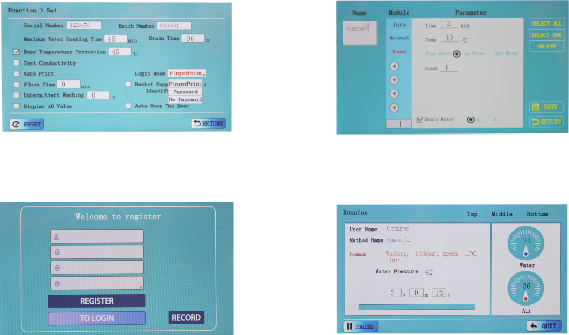

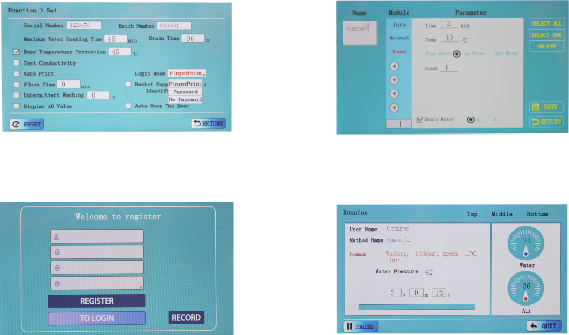

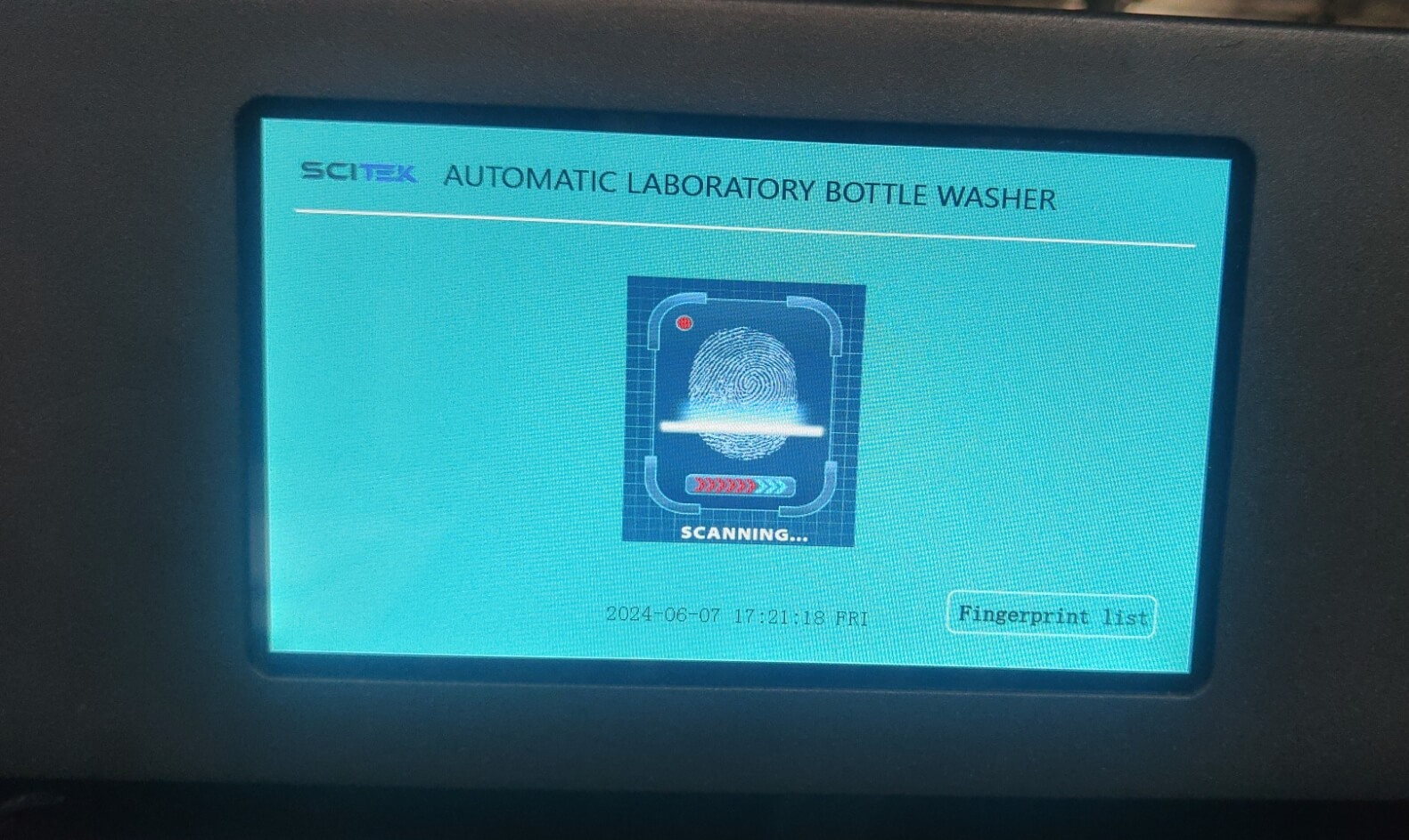

Advanced microcomputer control system with full color LCD touch screen:

Graphical and digital display of real-time water inflow, cleaning procedures, cleaning stages, columnar changes in time and temperature, pipeline pressure data and other parameters.

System software can be redesigned to meet customer needs, and it can support the expansion of hundreds of applications. The desktop can be configured to set up quick launch programs.

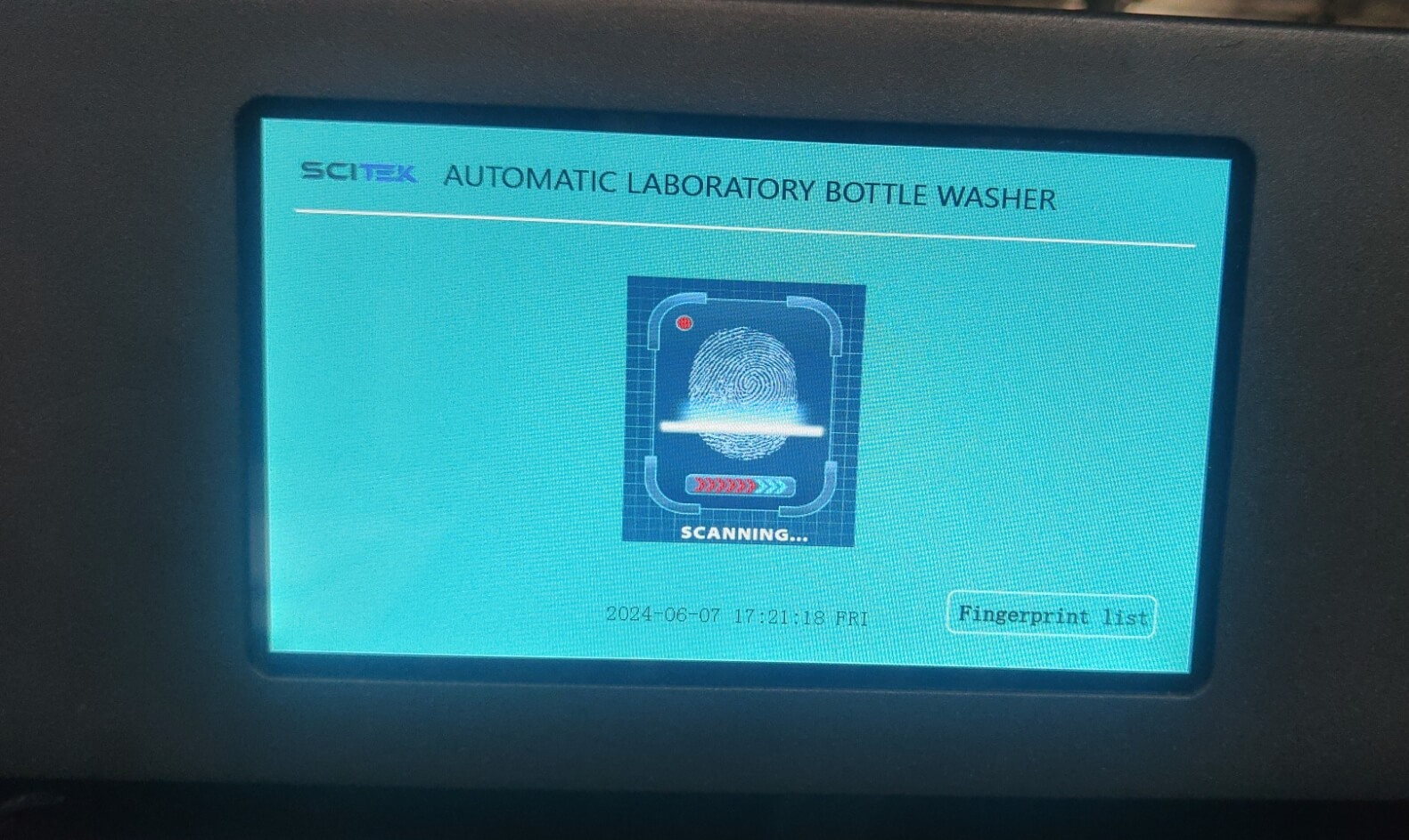

Three optional password protection can be set: Finger Print; Password; No password.

Advanced water spray technology

Pressure pipeline detection: The lab glass washer uses pressure detection sensors to real-time monitor the pressure of the cleaning water pipeline. When the water pressure is too low, it pauses the operation of the water pump to prevent it from running dry.

The circulating pump adopts soft start variable frequency control to avoid the damage caused by excessive water column pressure to glassware during the instantaneous start of the pump.

Two parallel water inlets at the back ensure uniform pressure distribution for each shelf and every spray nozzle.

1. Speed Sensor for Spray

2. Water Pressure Sensor

3. Flow Meter

4. Water Inlet Solenoid Valve

5. Pure Water Pump

6. Tap Water Pump

7. Thermostat Knob

8. Water Immersion Sensor

1. Fan

2. Heating pipe

3. Air filter

4. Heat Exchanger

Modular Design of FL-EXCH Racks

Each 1/2 module can be interchanged horizontally and vertically.

The lab glass washer's racks adopts a quick-insert design, making installation simple and concise.

Safety

Laboratory glassware washers help ensure the safety of laboratory personnel by eliminating the need for manual washing, which can be time-consuming and potentially hazardous. The automated cleaning process reduces the risk of injury from broken glassware or exposure to harmful substances. Water heating over-temperature protection, hot air heating over-temperature protection, water pump over-temperature protection, fan over-temperature protection.

Electronic security lock, EULA electric door switch technology, the experimenter can set the door opening temperature limit.

Laboratory Glassware Washer Specifications:

| Model | WD-160 | WD-190 | WD-230 | WD-230H | WD-320I | WD-320H | WD-680 |

| Capacity(L) | 158L | 185L | 223L | 223L | 317L | 317L | 680L |

| Display | 8.8inch LCD Touch screen | 7inch LCD Touch screen |

| Standard Program | 30 | 10 |

| Self-defined Program | 120 | 10 |

| Searchable Data Files | Cleaning program files; Cleaning record files; Monitor files |

| Storage | No | SD card(32G) | SD card and USB disk (32G) |

| Permission Management System | Three level | Four Level |

| Printer | No | Printer interface | Built in printer |

| Drying | Drying System | No | Double spray and heat exchange system with air inlet HEPA filter |

| Drying Time Range | No | 0 to 300mins |

| Drying Temp Range | No | RT to 120℃ |

| Drying Method | Chamber Forced Air Drying | Hot air injection via sprinkler (Circulation of hot air is not less than 110 m³/h) |

| Water Inlet pipe | Quantity | 2 |

| Length | Standard: 2m (Customizable) |

| Material | PVC |

| Water Pump | Brand | Sweden |

| Flow Rate | 0-400 L/min | 0-500 L/min | 0-600L/min

| 0-800 L/min | 0-800 L/min | 0-1600 L/min |

| Consumption | 0.37kW | 0.75kW | 0.75kW | 0.75kW | 1.5kW | 1.5kW |

|

| Pipeline Pressure Monitoring | No | Yes |

| Structure Material | External | 304 stainless steel |

| Cleaning Chamber | 316 stainless steel |

| Door | Automatic multi-touch intelligent door.

In standby mode, there is a gap between the front door and the cavity to facilitate water vapor evaporation. Automatically locks when cleaning starts. |

| Caster | Four universal casters at the bottom of the instrument for easy movement |

| Cleaning Rack | 1 layer | 2 layer | 2 layer | 2 layer | 3 layer | 3 layer | 6 layer |

| Air Heating Consumption | 0.5kW | 3kW | 3kW | 3kW | 4kW | 4kW | 8kW |

| Power Supply | 220/110 50/60Hz | 220/110, 50/60Hz | 380/220V 50/60Hz | 220/110V 50/60Hz | 380/220V, 50/60Hz |

| Total Consumption | 5kW | 5kW | 5kW | 10kW | 5kW | 10kW | 21kW |

| External Size(W×D×H)(mm) | 640x726 x778 | 670×691 ×940 | 670×760 ×1400 | 670×760 ×140 | 670×757×1650 | 670×757×1650 | 1560×790 ×1980 |

| Shipping Size(W×D×H)(mm) | 970x840 x1350 | 990x860 x1370 | 930x820x1620 | 890x880x1800 | 1680x910 x2100 |

| N.W./G.W. (kg) | 135/150 | 135/160 | 200/230 | 240/270 | 630/750 |

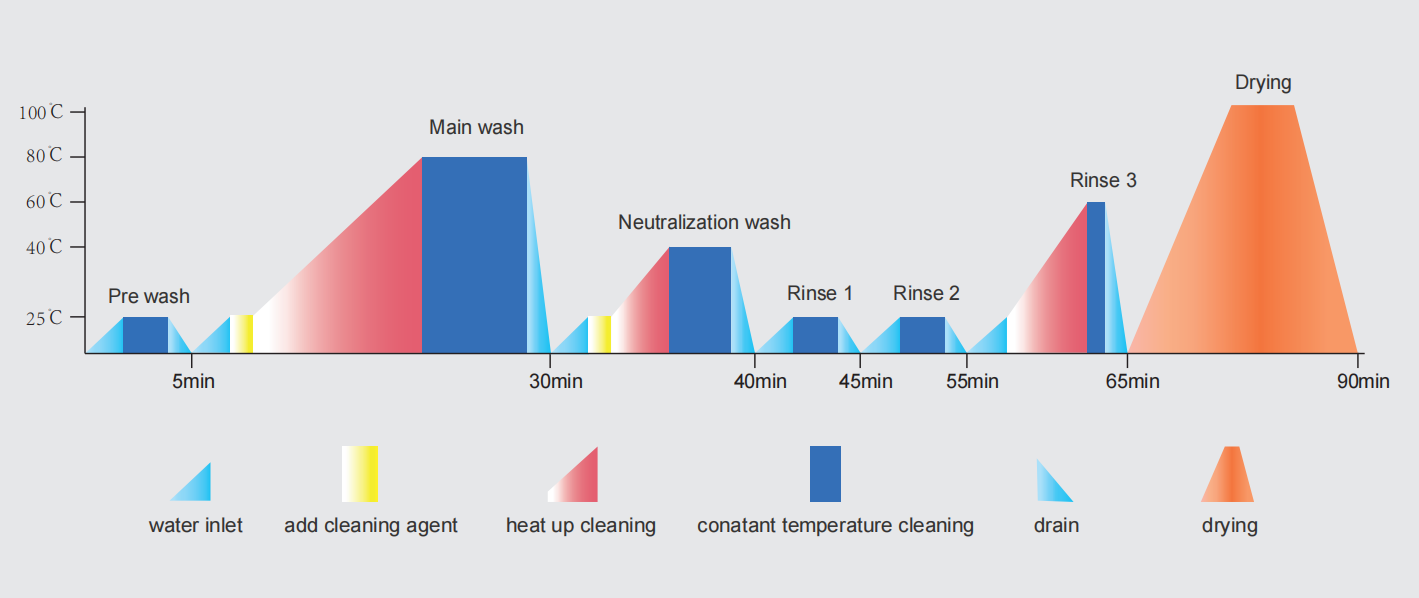

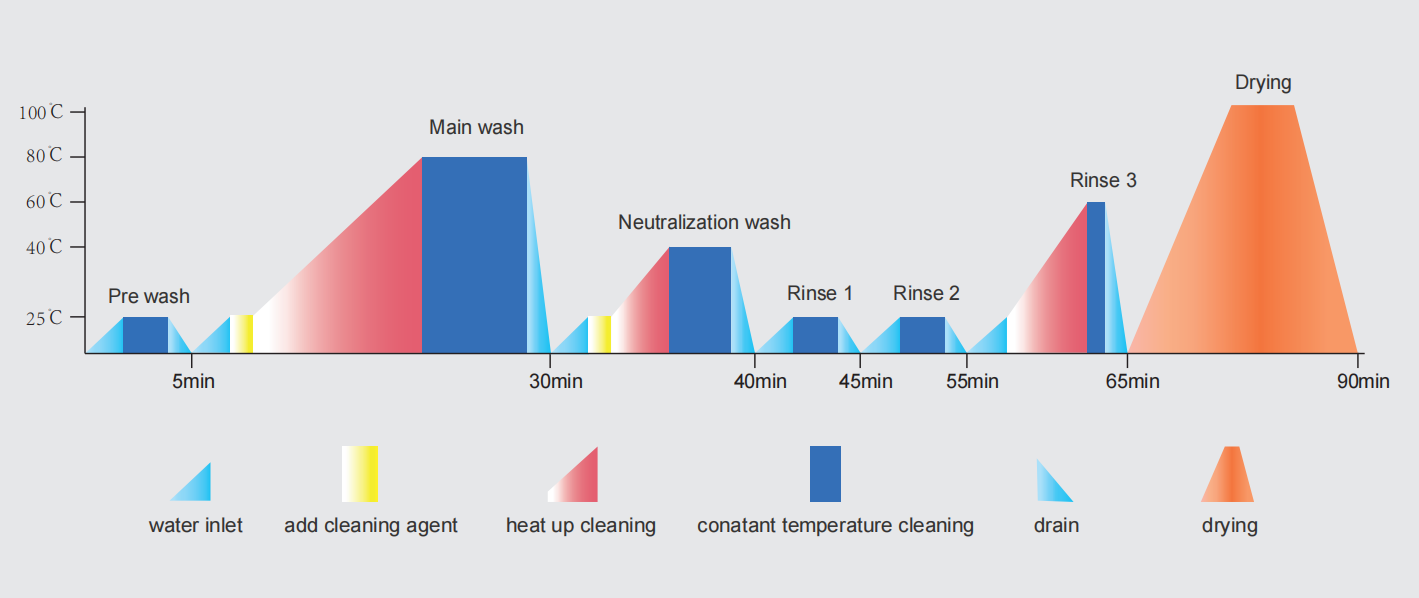

Laboratory glassware washer cleaning program and parameters:

| Time(min) | Temp(℃) | Alkaline (ml) | Acid(ml) | Water source |

| Pre-wash | 2 | 10 | 0 | 0 | Tap water |

| Main Wash | 15 | 70 | 50 | 0 | Tap water |

| Neutralization | 3 | 40 | 0 | 50 | Tap water |

| Rinse 1 | 1 | 10 | 0 | 0 | Tap water |

| Rinse 2 | 1 | 10 | 0 | 0 | Purified water |

| Rinse 3 | 1 | 60 | 0 | 0 | Purified water |

| Drying | 5 | 100 | 0 | 0 | / |

WD-160: Small size, the laboratory glass washer can be placed under the bench or on the bench, it is an economical and practical lab washer. (Commonly used cleaning racks: 1 unit XC-03/ 1 unit PLYT-21, 1unit PLWT-32)

WD-190: Small size, large cleaning volume, the drying function can select (Commonly used cleaning racks: 1 unit SC-01 and 1 unit XC-03/ 2 units PLYT-21 and 2 units PLWT-32)

WD-230/WD-230H: High-throughput cleaning while occupying a smaller footprint (Commonly used cleaning racks: 1 unit SC-01 and 1 unit XC-03/ 2 units PLYT-21 and 2 units PLWT-32)

WD-320I/WD-320H: Large cleaning volume, the laboratory glassware washing machine can place 3 layers of cleaning basket (commonly used cleaning racks: 2 units SC-01 and 1 unit XC-03/ 3 units PLYT-21 and 3 units PLWT-32)

WD-680: Simen control system, it can place 6 layers of cleaning basket. (Commonly used cleaning racks: 4 units SC-01 and 2 units XC-03/ 6 units PLYT-21 and 6 units PLWT-32)

Kindly note: All Cleaning racks are optional accessories

Cleaning Comparison:

Before cleaning grease contaminants

After cleaning grease

Details of Lab Glassware Washer (WD-190;WD-230;WD-680):

WD-190 glassware washing machine:

Laboratory glassware washers are secured on wooden pallets wrapped in clear protective film before shipping.

High-quality hoses, spray nozzles and filters and other accessories are all designed by the original manufacturer to be perfectly compatible with the laboratory glassware washing machine and ensure optimal performance of the equipment. The free cleaning fluids and accessories provided bring significant advantages to your laboratory cleaning solution.

WD-230 laboratory glassware washer:

The integrated design of the whole machine can be installed independently without the aid of other external devices. The laboratory glassware washing machine's shell material is 304 stainless steel and the cleaning chamber is 316L stainless steel, the cleaning chamber were formed directly without welding points.

With double spray heat exchange system and EU-W water-saving condensing technology. Double temperature monitoring system and optional drainage cooling and double drainage function.

Full color OLED LCD touch screen operating system with fingerprint recognition system and SD card data storage system: Screen has automatic sleep and manual wake-up function, cleaning program can display on screen in real-time.

Four buckets of 5L cleaning agent can be stored inside and four universal casters at the bottom of the lab glassware washer for easy movement.

Back water supply method with two parallel water supply: Pressure is uniform and the water outlet height is the same. Basket adopts FL-EXCH module design, every 1/2 module can be exchanged freely, basket frame and basket adopt quick-plug design, easy to install.

The circulating water can be adjusted from 0-600L/min. The lab glassware washers the pipeline pressure was monitored through pipeline pressure detection sensors in real-time and the pump can be stopped when the pressure is too low or disappear.

WD-680 laboratory glassware washing machine:

English

English