Application of IVC Cleaning System:

The use of an experimental animal cage cleaning machine during the cleaning process ensures the reliability of your research results.

Our system cleaning ensures the cleanliness of the animal facility. The perfect hygiene conditions are achieved through a high-quality system cleaning process.The fully automatic animal cage cleaning equipment is specifically designed based on the requirements of users in the experimental animal industry. It utilizes hot water combined with acidic or alkaline cleaning agents, high pressure, and high flow rate spraying method to achieve a fully automated spraying cleaning process for cages, cage covers, metal mesh frames, and water bottles.

Advantage of IVC Cleaning System:

1. Advanced Microcomputer control system with full color LCD touch screen

●The equipment is equipped with a PLC control system and a 10.2-inch touchscreen. The user can edit the cleaning program on the interface, such as cleaning water temperature, rinsing water temperature, cleaning time, rinsing time, and drainage time.

●Users can edit up to 24 different programs according to their needs. There are two cleaning modes available. One program combines alkaline cleaning and rinsing, while another program includes alkaline cleaning, acid neutralization, and high-temperature pure water rinsing.

2. Advanced cleaning system.

The equipment uses softened water as the working medium. Through a high-flow circulation pump, the water inside the cleaning chamber is circulated in the cleaning pipeline and sprayed onto the cage box through the spray arm, providing a powerful rinse for the items. The equipment's rinsing process involves directly spraying clean purified water from the water tank onto the cleaned cage box, achieving a clean rinsing effect. The high-temperature purified rinse water is recycled and used as the cleaning water for the next cycle, saving resources.

Acidic cleaning and alkaline cleaning

| Cleaning way | Acidic cleaning | Alkaline cleaning |

Usage | Effectively removes urine stains and lime deposits, especially suitable for cleaning animal cages and water dispensers.

| Effectively remove various organic residues in rodent cages. |

| Material Compatibility | Suitable for materials such as polystyrene (PS), polycarbonate (PC), polyetherimide (PEI), and stainless steel.

|

Automatic Spray Cleaning | Acidic liquid, highly efficient cleaning agent without surfactants | Alkaline liquid, an efficient cleaning agent that does not contain surfactants, phosphates and oxidants. It is recommended to use an acidic cleaning agent for neutralization after alkaline cleaning to avoid alkaline residues. |

| Drying | Adequate rinsing will prevent limescale spots from forming on the surface after drying. Polysulfone (PS) materials must use surfactant-free cleaning agents

|

3. Advanced Flushing System

●An independent rinse water pump with a rated flow rate of 45L/min is capable of providing spray rinsing at a head of 17 meters. The power consumption is ≤0.3kw. It is equipped with an independent temperature-controlled water tank, as well as separate spray piping and spray water pump. The pump does not participate in the cleaning process, ensuring the absolute cleanliness of the spray water.

●The rated flow rate of the cleaning circulation pump is 500L/min at a head of 13 meters. The power consumption is ≤1.5kw. The pump head is made of 316 stainless steel for spray cleaning. It is equipped with a soft start frequency conversion function to reduce the damage to the equipment caused by excessive spray pressure during pump startup.

●Cage box placement method: The cage boxes inside the cleaning chamber can be tilted and placed horizontally freely. The cleaning rack can be adaptively adjusted to simultaneously accommodate various types of cages, such as those for mice, guinea pigs, and rabbits.

4. Safety System

●Door lock device: The door cannot be cleaned when it is in the open position.

●Emergency braking device: The control panel is equipped with an emergency braking device.

●Power failure protection device: Automatically shuts off the water and steam pipelines in the event of a power failure.

●Abnormal situation alarm: Audible and visual alarm.

IVC Cleaning System Specifications:

| Model | IVC-100 |

| Capacity(L) | 1200L |

| Display | 10.2 inch LCD touch screen |

| Standard Program | 24 |

| Cleaning System | Cleaning Method | Spray cleaning |

| Main Washing Temperature | ≤50℃ (Adjustable) |

| Rinse Temperature | ≤80℃ (Adjustable) |

| Lotion Pump | 1100ml/min |

| Cleaning Spout | ≥44 units |

| Rinse Spout | ≥86units |

| Cleaning Layers | 2 Layers |

| Maximum Cleaning Height | 340mm/layer |

| Washable Cages | 28 units |

| Water Inlet Pipe | Quantity | 1 |

| Length | 2m |

| Material | Food grade silicone tube |

| Water Outlet Pipe | Quantity | 1 |

| Length | 2m |

| Material | PE |

| Water Pump | Brand | World-renowned brand |

| Flow Rate | 500L/min |

| Consumption | 1.5 kW |

| Structure | Material | External | 304 stainless steel |

| Cleaning Chamber | 304 stainless steel |

| Door | Single door |

| Caster | Four universal casters at the bottom of the instrument for easy movement |

| Total Consumption | 20Kw |

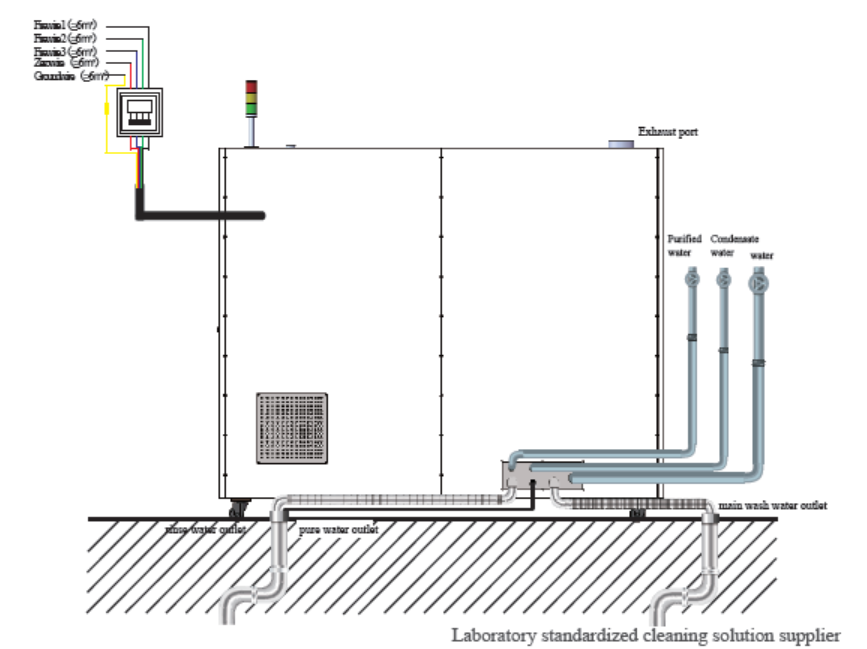

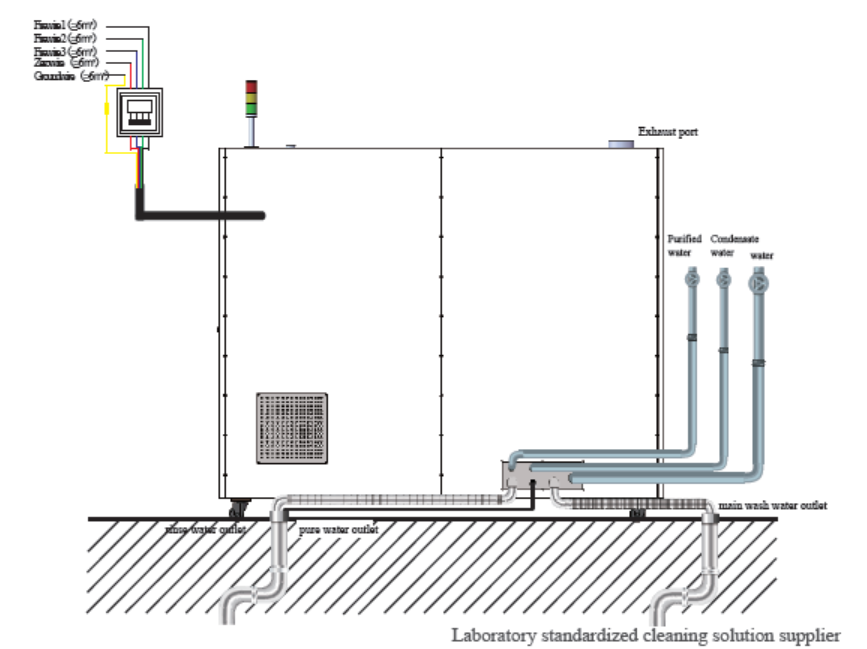

| Power Supply | 380V, 50/60Hz |

| External Size(W×D×H)(mm) | 2050x850x1950 |

| Shipping Size(W×D×H)(mm) | 2200x1030x2170 |

| N.W./G.W. (kg) | 850/900 |

English

English