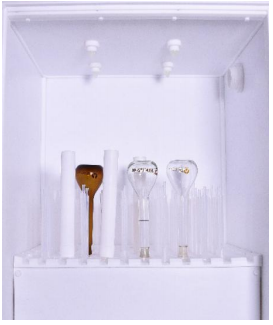

The acid steam cleaning system can safely and efficiently remove inorganic elemental residues from various vessels such as Microwave digestion tubes, volumetric flask, triangular flask, etc. It effectively reduces ion background and meets the cleanliness requirements of vessels for trace inorganic element detection using ICP-MS, atomic absorption, atomic fluorescence, and other equipment. It improves experimental efficiency, reduces operational risks, and protects the laboratory environment.

Acid Steam Cleaning System Advantages:

1. Environmentally friendly and pollution-free.

The used acid or water does not flow back into the original acid or water, but is stored in a waste liquid collector. It is automatically monitored for pH and automatically neutralized before being discharged when it reaches a neutral state.

Built-in EP exhaust gas absorption system can instantly absorb a large amount of exhaust gas without the need for a fume hood.

2. Save acid consumption and reduce cleaning costs.

Patented three-link dynamic acid tank, fast heating, acid vapor speed is three times that of ordinary heating tanks, acid vapor can be produced in 5 minutes, after acid vaporization, the acid tank automatically tilts to drain the acid, ensuring thorough rinsing of the acid tank with water, and no residual acid after cleaning. Only 70ml of acid is needed for one cleaning. It greatly reduces the consumption of acid, saving costs.

3. Excellent corrosion resistance.

The entire cleaning chamber is made of PFA and PTFE materials, exhibiting excellent corrosion resistance. The electronic operating system is separated from the instrument, and circuit boards are designed with corrosion-resistant coatings, enhancing system stability.

4. The acid steam cleaning system is fully automated, combining acid vapor cleaning, ultra-pure water spraying, and drying into one integrated process.

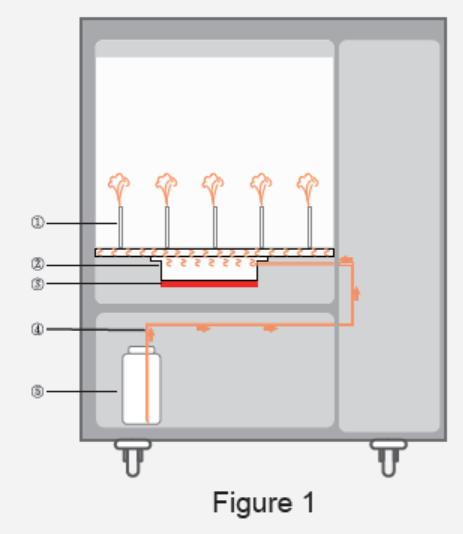

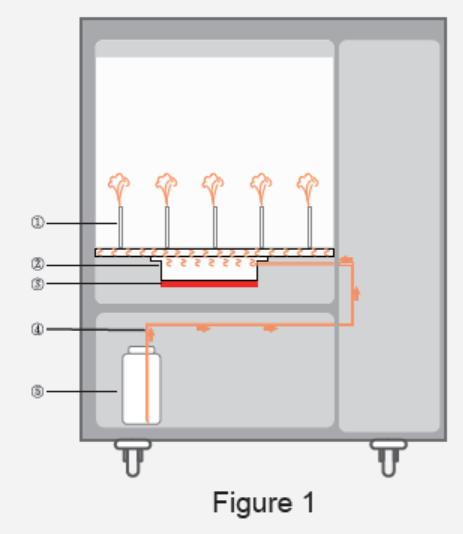

①Catehter

②Acid tank

③Heating plate

④Acid tubing

⑤Acid bottle

Injected sub-boiling acid steam cleaning (Figure 1)

The pure acid vapor cleans the inner wall of the vessel through the catheter, effectively reducing the ion residue, and it is discharged after use without reflux; the sub-boiling temperature acid steam cleaning for 1 hour is equivalent to soaking.

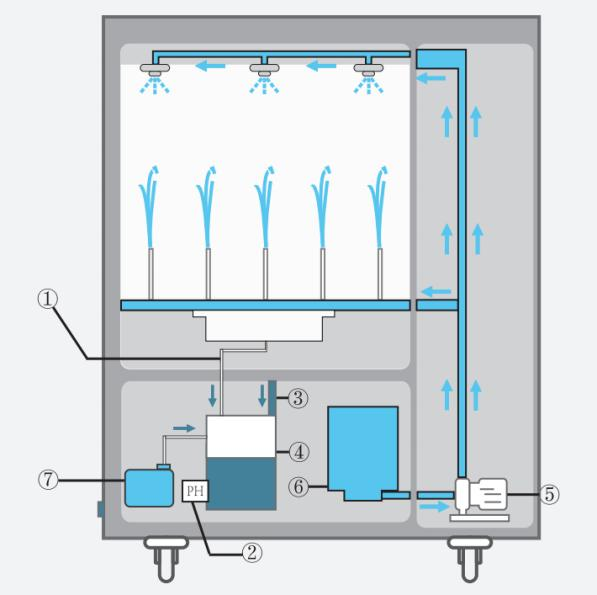

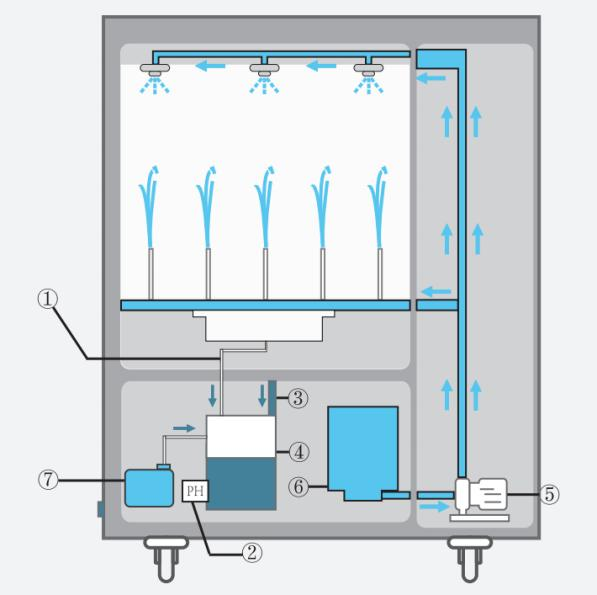

① Acid drain tubing

② pH detection

③ Acid Spray waste tubing

④ Wastewater neutralization bucket

⑤ Water pump

⑥ Ultra-pure bucket

⑦ Lye barrel

Ultra-pure water injection flushing (Figure 2)

Built-in self-priming pump for automatic addition of ultra-pure water, and automatic water storage in the pure water tank. The pure water tank has a liquid shortage reminder and automatic stop when full function. "Non-reflux" ultra-pure water flushing ensures no acid gas and acid residue in the cavity.

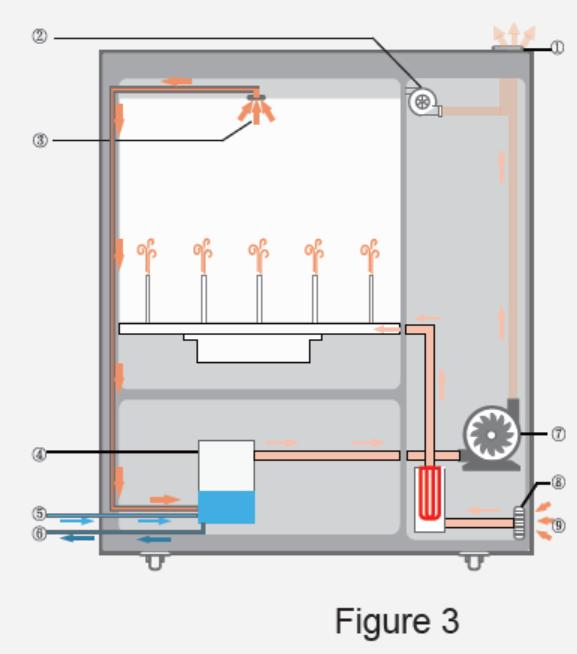

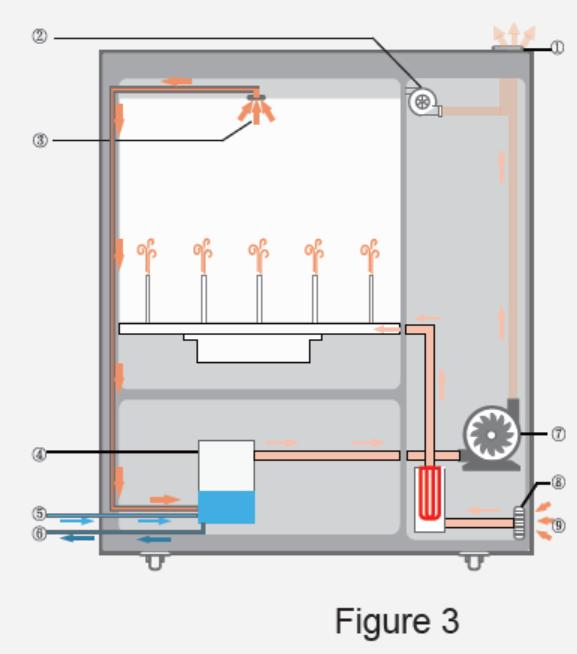

①Exhaust port

②Exhaust fan

③Air outlet

④Absorption tank

⑤Water tubing

⑥Tap water drainage tubing

⑦Internal exhaust fan

⑧HEPA filter

⑨Air inlet

Hot air drying (Figure 3)

The drying temperature is RT-120℃, the drying time is from 0-300min, and the flow rate is 168m3/h. The pipeline compression fan blows the hot air filtered through the HEPA filter into the vessel. The drying temperature, drying time, and airflow rate can be adjusted.

Acid Steam Cleaning System Specifications:

| Model | ASCS-3300 |

| Capacity(L) | 87L |

| Display | 7 inch LCD touch screen |

| Standard Program | 20 |

| Permission Management System | 3 Level |

| Cleaning | Consumption of Acid | 70ml (1ml/min) |

| Cleaning ≥49 units of 100mL microwave digestion tubes at once |

| Drying | Drying system | Hot air injection via Sprinkler |

| Drying Time Range | 0 to 300mins |

| Drying Temp Range | RT to 100℃ |

| Airflow Rate for Drying | 168m³/h. |

| Drying Method | Hot air injection via Sprinkler |

| Water inlet pipe | Quantity | 2 |

| Length | 3m ( Customizable) |

| Material | PTFE |

| Water Pump | Brand | World-renowned brand |

| Flow Rate | 120L/min |

| Consumption | 0.75kW |

| Structure | Material | External | 304 stainless steel |

| Cleaning chamber | PTFE |

| Door | Double-door design, for enhanced safety. |

| Caster | Four universal casters at the bottom of the instrument for easy movement |

| Total Consumption | 1.5kW |

| Power Supply | 220/110V, 50/60Hz |

| External Size(W×D×H)(mm) | 682x663x1624 |

| Shipping Size(W×D×H)(mm) | 880x860x1880 |

| N.W./G.W. (kg) | 220/249 |

| Residue after cleaning can reach ppt or no detection level, we have strict cleaning data verification report. |

|

| Sample | Pb[ He ] | As[ He ] | Cd[ He ] | Cr[ He ] | Mg[ He ] | Cu[ He ] | Fe[ He ] |

| [ug/l] | [ug/l] | [ug/l] | [ug/l] | [ug/l] | [ug/l] | [ug/l] |

| Sample1 | 0.00 | 0.01 | 0.01 | 0.00 | 0.00 | 0.01 | 0.00 |

| Sample2 | 0.00 | 0.00 | 0.00 | 0.02 | 0.00 | 0.00 | 0.01 |

| Sample3 | 0.01 | 0.00 | 0.01 | 0.01 | 0.02 | 0.01 | 0.02 |

| Sample4 | 0.00 | 0.01 | 0.01 | 0.00 | 0.00 | 0.01 | 0.01 |

| Sample5 | 0.01 | 0.00 | 0.00 | 0.00 | 0.01 | 0.00 | 0.00 |

| Sample6 | 0.00 | 0.01 | 0.00 | 0.00 | 0.00 | 0.01 | 0.01 |

Application of Acid Steam Cleaning System:

Powerful acid steam technology quickly dissolves all types of dirt and ensures thorough cleaning. Used in a variety of scenarios such as industrial equipment, machine parts, and other versatile applications. Whether it's grease, adhesions or hard-to-clean contaminants, our Acid cleaners make it easy to tackle and ensure that equipment looks brand new.

Industrial Manufacturing: Acid vapour cleaning of industrial equipment, machinery parts and production lines to ensure that the surfaces of the equipment are free from dust and contamination.

Healthcare: Cleaning of medical equipment, instruments and laboratory equipment to ensure that they meet high standards of hygiene and sterilisation.

Pharmaceutical Industry: For pharmaceutical equipment, containers and process pipework to ensure a high level of purity and a sterile environment for pharmaceutical production.

Packing & Delivery

Adopting standard international export packaging, the packaging can adapt to long-term international transportation.

We provide sea freight, air freight, land freight, express service, accept EXW, FCA, FAS, FOB, CFR, CIF, CPT, CIP, DAF, DES, DEQ, DDU, DDP and other trade terms.

Pre-sale services

●24-hour quick response to customer inquiries.

●Recommend models that meet customer requirements.

●Provide competitive prices and detailed product parameters and related information.

●Provide product customization services.

●Sample testing support, production view service.

After-sales service

●Product installation and use training.

●Provide overseas maintenance services in response to customers technical problems.

●Three-year warranty on air protection products, life time maintenance service.

●Online and offline technical personnel training services.

FAQ

What type of acid cleans glass?

Nitric Acid Cleaning (HNO3CLEAN)

This procedure typically requires approximately 35 minutes for completion. Ensure the use of proper protective equipment, including eye protection and nitrile gloves, as nitric acid is involved. The application of nitric acid proves effective in the cleaning of glass, as it actively extracts ions from the surface of the glass material.

English

English