The amount of dissolved calcium and magnesium ions in water can affect many experiments and processes. Water hardness tests need to be performed before experiments to ensure the results' accuracy. And using hard water in experiments may lead to scale formation inside the instrument. This can reduce the testing accuracy and service life of the instrument. In order to better understand water hardness, how to detect water hardness, and how to reduce water hardness and a series of issues, we will discuss this article in depth together.

What is water hardness?

When water comes into contact with underground rocks and soils, it dissolves their minerals, including metal ions such as calcium and magnesium. The concentration of calcium and magnesium in natural water generally far exceeds that of any other multivalent cation. Therefore, hardness is usually considered the concentration of calcium and magnesium ions in water. These ions cause water to become hard, thus affecting its properties and uses. Depending on the degree of hardness, water can be categorized as soft water, medium hard water, and hard water.

Soft water: 0-60 mg/L

Medium hard water: 60-120 mg/L

Hard water: 120 mg/L and above

Water hardness impacts many experiments and processes, so water hardness testing is required in laboratories and industrial production.

Carbonate and non-carbonate hardness

Another way of determining water hardness is carbonate hardness and non-carbonate hardness. Carbonate hardness is the bicarbonate content of calcium and magnesium that we wrote about above. This is also known as temporary hardness because boiling can remove or reduce it. When such bicarbonates are heated, they precipitate as solid carbonates. This is the main cause of scaling in water heaters and boilers.

On the other hand, non-carbonate hardness is caused mainly by nitrates, chlorides, and sulfates of calcium and magnesium. Non-carbonate hardness is sometimes called permanent hardness. If you need to reduce the hardness of this type of water in a laboratory, heating alone will not work. You can take ion exchange, reverse osmosis, and chemical precipitation treatment.

So, how does a laboratory or other industry that requires high water hardness determine the level of carbonates and non-carbonates?

The relationship between alkalinity and water hardness

Trying to determine the amount of carbonate and non-carbonate hardness can be determined by measuring alkalinity. Alkalinity is the ability of water to neutralize acids. If alkalinity equals or exceeds hardness, all hardness is carbonate. Any hardness in excess is non-carbonate hardness. Here is the relationship between alkalinity and hardness:

Alkalinity = 2 × carbonate hardness

Why measure water hardness?

Laboratories use water for centrifuges, ultrasonic cleaners, pipettes, and other laboratory equipment. If the water is hard, solid deposits can easily form inside the instrument, damaging the equipment's accuracy. Soft water, on the other hand, maybe corrosive. Therefore, it is important to measure and understand the hardness level of the process water. We often need to soften water by precipitation or ion exchange to remove hardness before an experiment. In order to optimize these processes, it is sometimes important to monitor calcium and magnesium levels individually, as well as total hardness.

In addition, magnesium can interfere with other water quality tests, such as nitrogen and ammonia salicylate. Below is a list of test equipment to detect or manage calcium and magnesium levels in water:

| Instrument | Feature | Application |

Titration burette | Specific titration methods and calculation formulas will vary depending on the indicator and reaction system used. Pros:

Relatively inexpensive, suitable for general educational experiments or tests requiring low accuracy

Cons:

Time-consuming, not suitable for rapid testing

Requires the use of chemical reagents and the accuracy of the results is affected by the skill of the operator.

Does not provide separate concentrations for calcium and magnesium. | Education, small-scale water treatment facilities

|

| Water Hardness Meter | Pros:

Easy to use, no chemicals required

Quickly measures the total hardness of a water source

Generally small enough to be carried around for field tests and non-professional use.

Cons:

Cannot analyse calcium and magnesium in water.

Not suitable for high precision requirements | Water treatment industry, drinking water monitoring, household water testing. |

| Ion Chromatograph (IC) | Pros:

Highly accurate, analyses a wide range of ions, including calcium and magnesium.

Can provide separate measurements of calcium and magnesium

Cons:

Expensive equipment

Requires specialised knowledge and handling

Not suitable for rapid testing | Environmental monitoring, food and beverage, pharmaceuticals |

| Atomic Absorption Spectrometer (AAS) | Pros: High accuracy for measuring a wide range of metallic elements, including calcium and magnesium Can be used with a wide range of sample types

Cons:

Expensive equipment

Requires specialised knowledge and chemicals

Not suitable for rapid testing | Environmental analysis, food and beverage industry, pharmaceuticals, metal industry |

| ICP-MS | Pros:

Very high accuracy and sensitivity for the measurement of a wide range of metallic elements, including calcium and magnesium

Suitable for a wide range of sample types

Cons:

Very expensive equipment

Requires a high degree of expertise and handling

Usually only suitable for large laboratories | Environmental analysis, geology, pharmaceuticals, metal analysis, mining |

| Spectrophotometer | Pros:

Relatively low cost

For measuring the ionic content of specific reagent colour reactions

Suitable for rapid testing

Cons:

Usually only provides relatively rough estimates

Results are affected by reagent and reaction conditions | Education, drinking water monitoring, simple laboratory tests |

Each water tester has unique application areas and benefits, and the specific choice depends on the accuracy, speed, cost, and operation required. In practical applications, combining several methods to obtain a more comprehensive analysis may be necessary.

How to test hardness water?

In everyday life or before an experiment, if you only want to measure the hardness of the water and do not want to know the ion content or a more precise test value. You can choose the following method for a quick test:

Use test paper. Soak the test paper in the water sample to be tested and compare it with the color comparison chart. This will quickly determine the hardness level of the water.

Water testing kit: This is a kit used for testing water quality and may contain tools such as cuvettes, stirring rods, burettes, and so on.

The handheld digital meter is easy to carry and is used to test the different chemicals present in the water.

Water hardness meter: This is one of the most common and frequently used water quality testing instruments. It is generally small and portable and supports quick measurements.

However, such tests are usually used for preliminary checks, as their accuracy is difficult to compare with that of specialized analyses conducted under laboratory conditions.

In water quality testing, sampling depends on the purpose of the analysis. Each purpose has its water sampling requirements and provides specific results. If these requirements are addressed, the results will be limited and meaningful.

For example, when sampling from a water supplier for microbiological examination, the water sample is taken at the transition from the water supplier to the house. If a treatment plant is installed, timely sampling is also necessary. Otherwise, only limited or can obtain no meaningful results.

Featured products for measuring water hardness

Water hardness meter:

WH-P322 USB Interface

Range (Concentration) : 0.05 to 200mmol/L

Calibration Points : 1 point, reading ±10°C

Sizes(W×D×H)(mm) : 170×85×30

WH-B932 USB Interface

Range (Concentration) : 0.05 to 200mmol/L

Calibration Points : 2 to 5 points

Sizes(W×D×H)(mm) : 310× 240×190

Spectrophotometry:

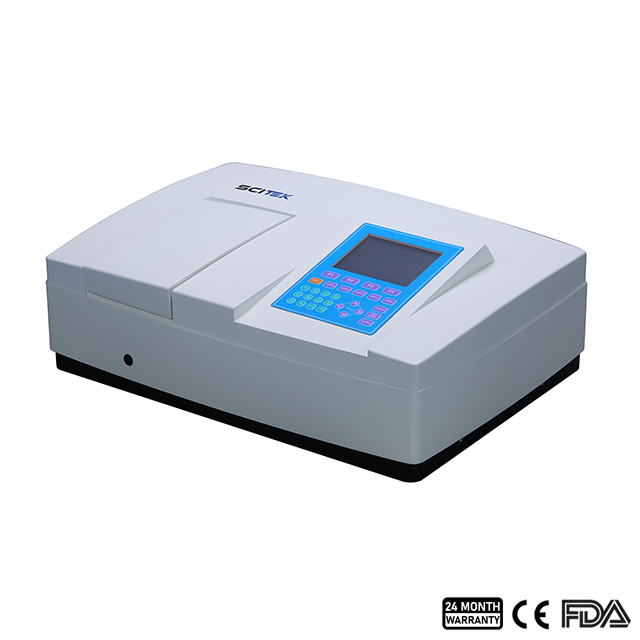

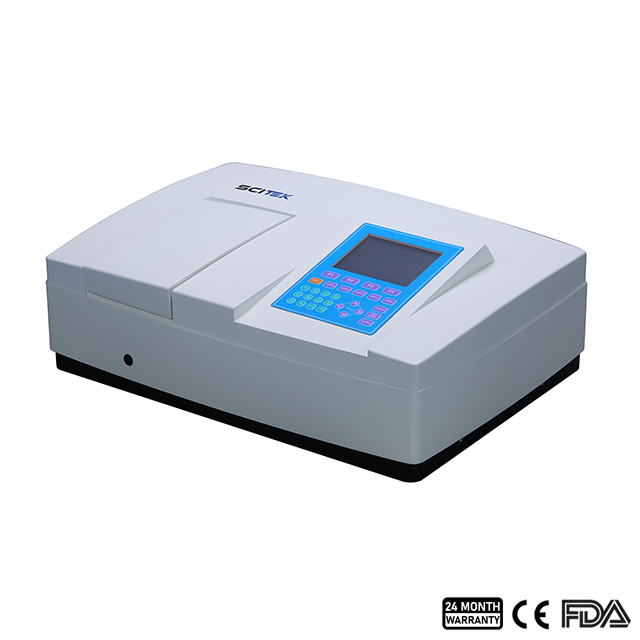

SP-UV6100 Single Beam UV VIS

Wavelength Range : 190-1100nm

Wavelength Accuracy : ±0.1nm@656.1nm, ±0.3nm@all

Printer Port : Parallel Port

Size(W×D×H)(mm) : 625x430x206

SP-DUV8000 Double Beam UV VIS

Wavelength Range : 190-1100nm

Wavelength Accuracy : ±0.1nm@656.1nm, ±0.3nm@all

Print Port : USB Port

Size(W×D×H)(mm) : 630x430x210

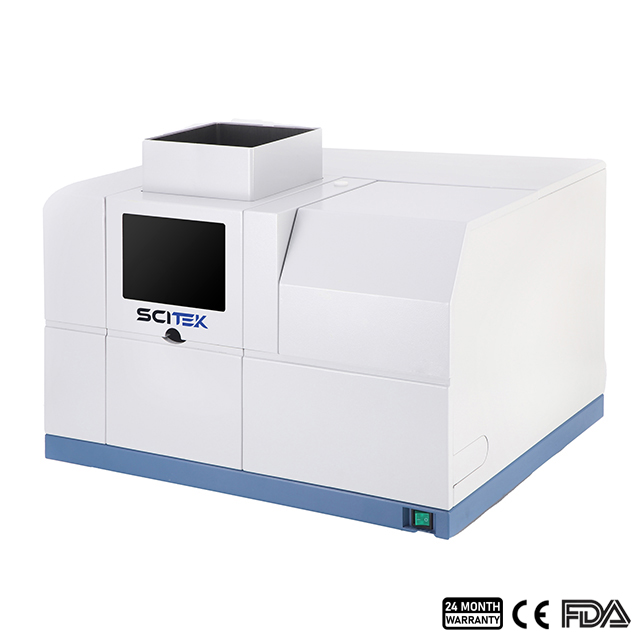

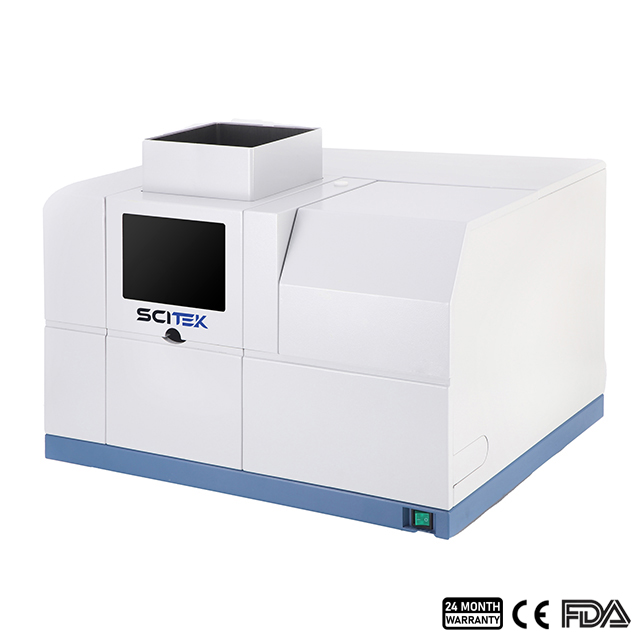

SP-AA4530 AAS

Wavelength range : 190-900nm

Accuracy of the wavelength : ±0.15nm

Receptivity of the wavelength : ≤0.04nm

Size(W×D×H)(mm) : 730×625×700

Titrator:

Hardness can also be measured accurately using a digital titrator. Digital titrators dispense EDTA solutions in very small increments with greater precision.

Test Strips:

When a water hardness test strip is immersed in a water sample, colors appear on the strip and match the strip to a chart. The chart shows colors for 0, 25, 50, 120, 250 and 425 ppm concentrations or 1, 1.5, 3.7, 15 and 25 gpg. Use test strips when the general hardness range is sufficient. Test strips should not be used when precise hardness values are required.

How to reduce water hardness

In order to reduce unwanted hardness, they must soften water. Softening methods usually fall into two main categories:

Ion exchange softening process

This is one of the most commonly used water treatment methods in laboratories and the industry. The process uses natural or synthetic ion exchange resins to remove calcium and magnesium ions from water. Different ion exchange resins have other properties. Synthetic materials tend to have a higher exchange capacity, so they are better suited to removing higher hardness levels.

Most resins can be regenerated once their exchange capacity is exhausted, so it is important to monitor effluent hardness to determine when the column needs to be regenerated. In this two-step process, the unit is first rinsed to remove deposits. A brine solution is then circulated through the resin under certain conditions to replace accumulated calcium and magnesium ions with cations initially used for softening.

Advantages:

The method does not significantly affect other characteristics of the water, such as the pH value.

The process also removes hardness-causing cations other than magnesium and calcium.

This process reduces the hardness to near zero.

Disadvantages:

High levels of iron or manganese in the water can contaminate the ion exchange resin.

Sodium resins can increase the sodium content of the finished water and interfere with some ULR hardness monitoring methods.

High solids levels can contaminate the resin bed, resulting in additional costs.

Precipitation softening process

Precipitation is usually accomplished through the lime soda process. When lime is added to hard water, it reacts with the carbonate hardness to produce solids. Lime and soda ash can be used together to remove carbonate and non-carbonate hardness. Magnesium precipitation requires twice the amount of chemical additives and produces twice the amount of sludge that needs to be removed compared to calcium precipitation. Remove excess carbon dioxide before softening, as it can impede lime precipitation.

Advantages:

This process removes excess iron and fluoride.

This process may remove bacteria and viruses due to the high pH value.

Corrosion and scale formation can be controlled by this method with proper controls.

Disadvantages:

It produces a large amount of sludge that needs to be disposed of.

Operational and chemical costs are high.

Adding soda ash may affect the sodium content of the water.

Recarbonation or reintroduction of carbon dioxide is necessary to lower the pH after softening.

This process does not reduce hardness to zero.

The process requires a high degree of operator skill to control.

Boiling

Boiling water reduces the amount of calcium and magnesium in the water by causing the calcium and magnesium carbonates in the water to precipitate to the bottom. However, this method is only suitable for small quantities of water rather than for treating large quantities.

Advantages:

Simple and low cost

Boiling can treat small quantities of water, e.g., cooking, drinking water, etc.

Disadvantages:

Boiling can only remove calcium and magnesium carbonate from water and is ineffective in reducing water hardness for other forms of hardness, such as calcium sulfate and magnesium chloride.

Only suitable for small amounts of household water treatment

Cannot remove other pollutants from water

Which processes require water hardness monitoring?

Drinking water industry: Water hardness is also one of the parameters to be monitored in drinking water treatment. Too much hardness in the finished water may lead to scaling, which can hurt the taste and quality of the drinking water, as well as the pipes, taps, etc. If the water is too soft, it can lead to corrosion of the pipes. If the water is too soft, it can lead to corrosion of pipes.

Wastewater: The discharge of water hardness wastewater into natural bodies of water may build sediments and affect the balance of the water ecosystem. Therefore, different regions or countries require monitoring reports on the hardness of wastewater from industrial or commercial enterprises to ensure that wastewater discharges comply with environmental standards and regulatory limits.

Detergent and soap production: The production of detergents and soaps requires the monitoring of water hardness, as soft and hard water have different effects on the product's performance.

Swimming pools: Water hardness monitoring ensures that swimming pools and spas have the right quality of water to maintain hygiene and equipment performance.

Chemical Manufacturing Industry: In chemical manufacturing processes, changes in water hardness may affect the reaction's effectiveness. High water hardness may affect reaction rates, product purity, yields, etc.

Boiler and cooling water treatment: The level of water hardness can affect the performance of boiler and cooling water systems. Excessive water hardness may lead to fouling of boilers, pipes, condensers, etc., which can cause damage and loss of revenue.

Food industry: In food and beverage manufacturing, monitoring water hardness is critical to controlling product quality. It can affect the taste, color, and texture of food products.

Pulp and paper industry: Water hardness can affect the quality and performance of paper. High water hardness can cause fibers and fillers to precipitate, making the paper's surface less smooth and increasing the roughness of the paper. It can also cause the paper's pH unstable, making it susceptible to yellowing and brittleness.

What is the normal hardness of water in ppm?

The "normal" or typical water hardness in terms of total hardness is often measured in parts per million (ppm) or milligrams per liter (mg/L) as calcium carbonate (CaCO3). Here is a general classification for water hardness:

Soft water: 0-60 ppm (or mg/L) as CaCO3

Slightly hard water: 61-120 ppm (or mg/L) as CaCO3

Moderately hard water: 121-180 ppm (or mg/L) as CaCO3

Hard water: 181-250 ppm (or mg/L) as CaCO3

Very hard water: Over 250 ppm (or mg/L) as CaCO3

It's important to note that these ranges are not strict and can vary depending on local standards and personal preferences.

What is a good level of hardness in water?

The "good" level of water hardness can vary depending on the specific application or preference, but here are some general guidelines for water hardness in lab and home settings:

Lab water hardness:

Low to Moderate Hardness (Soft to Slightly Hard): For most laboratory applications, it's ideal to have water with low to moderate hardness. Soft water (0-60 mg/L as CaCO3) is often preferred to prevent interference with analytical processes and to minimize the risk of scale formation in lab equipment.

Home water hardness:

Personal Preference: In a home setting, water hardness can be a matter of personal preference. Some people prefer soft water because it tends to be easier on the skin and results in less scale buildup on fixtures and appliances. Others may prefer slightly hard water because they believe it is healthier. Generally, water is considered:

Soft: 0-60 mg/L as CaCO3

Slightly Hard: 61-120 mg/L as CaCO3

It's worth noting that water hardness can vary widely by location, so the natural water source in a specific area will determine the baseline hardness level. In some regions, water may be naturally soft, while in others, it can be quite hard. In cases where water is too hard for personal preference, water softeners can be used to reduce hardness.

The specific hardness level you consider "good" may also depend on the intended use. For drinking water, personal preference is a key factor. For appliances and plumbing systems, it's often better to have slightly hard water to reduce the risk of corrosion and scale buildup, but not so hard that it causes problems.

Ultimately, the definition of "good" water hardness is subjective and can vary from one situation to another. It's important to consider both personal preference and practical concerns when determining what is suitable for a given application.

English

English