Many people may think of using an acid cleaner to remove solid calcification or metal build-up from the surface of a material. However this traditional acid cleaning process is a safety hazard.

Scitek has researched a new acid steam cleaning system - the ASCS-3300 acid cleaner. Our acid cleaner is designed to easily tackle stubborn stains, mineral deposits, rust, and other stubborn contaminants.

What is acid cleaner

Acid cleaner can safely and effectively remove residues of inorganic elements in various containers, such as volumetric flasks, microwave digestion tubes, test tubes, beakers, triangular flasks, atomizers and torch tubes of ICP and other experimental vessels made of glass and quartz materials. It can effectively reduce the ionic background and meet the cleanliness requirements of containers for detecting trace inorganic elements in ICP-MS, atomic absorption, atomic fluorescence and other equipment. The general cleaning time is about 2-4 hours, applicable to reagents such as hydrofluoric acid, hydrochloric acid, nitric acid, sulphuric acid, and water. It is an automatic, airtight, acid-vapor cleaning instrument.

Acid cleaner working principle

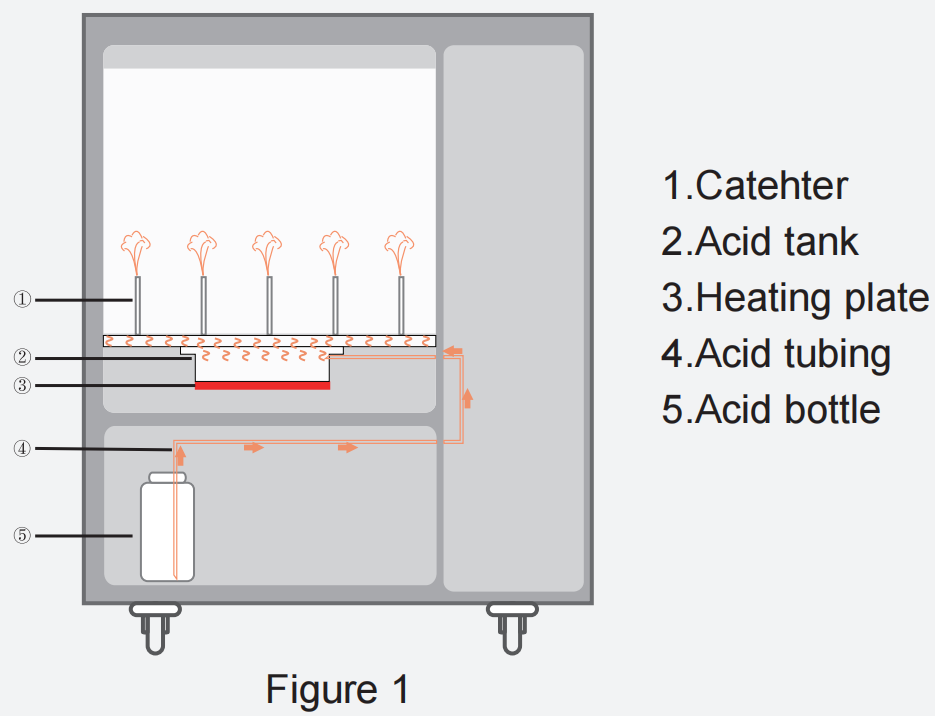

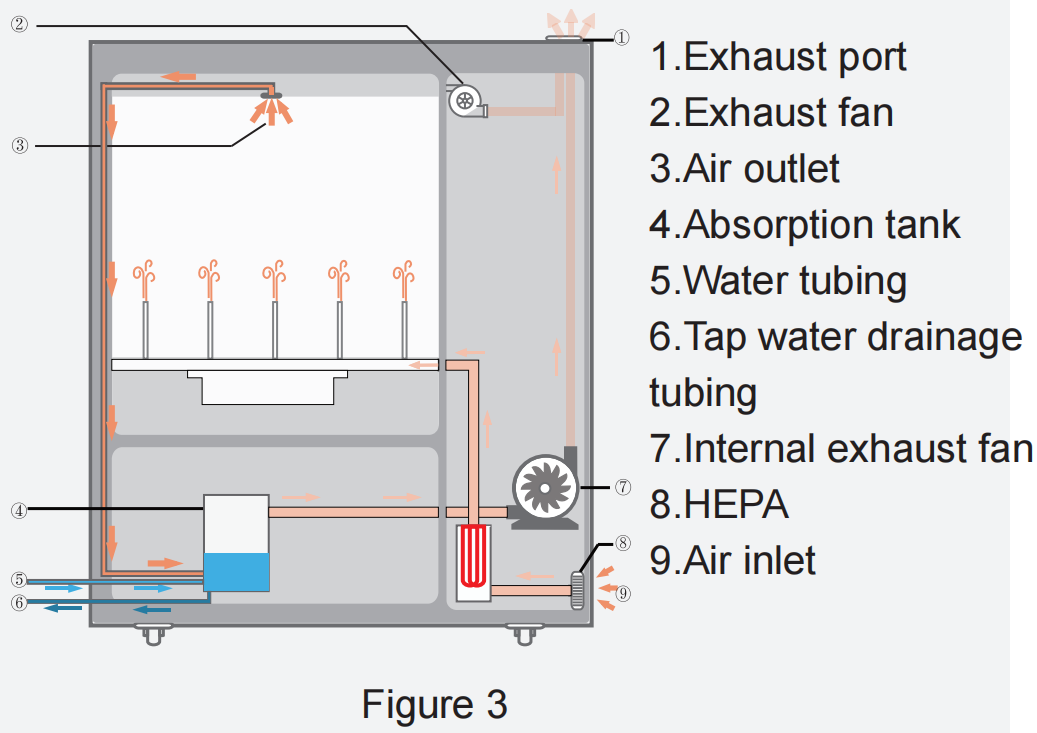

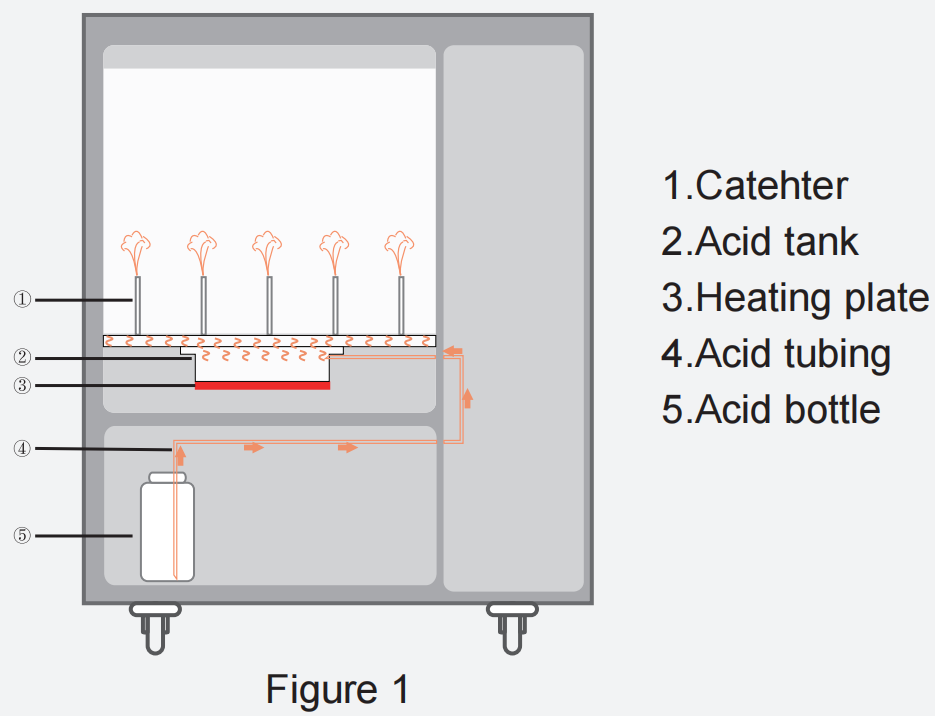

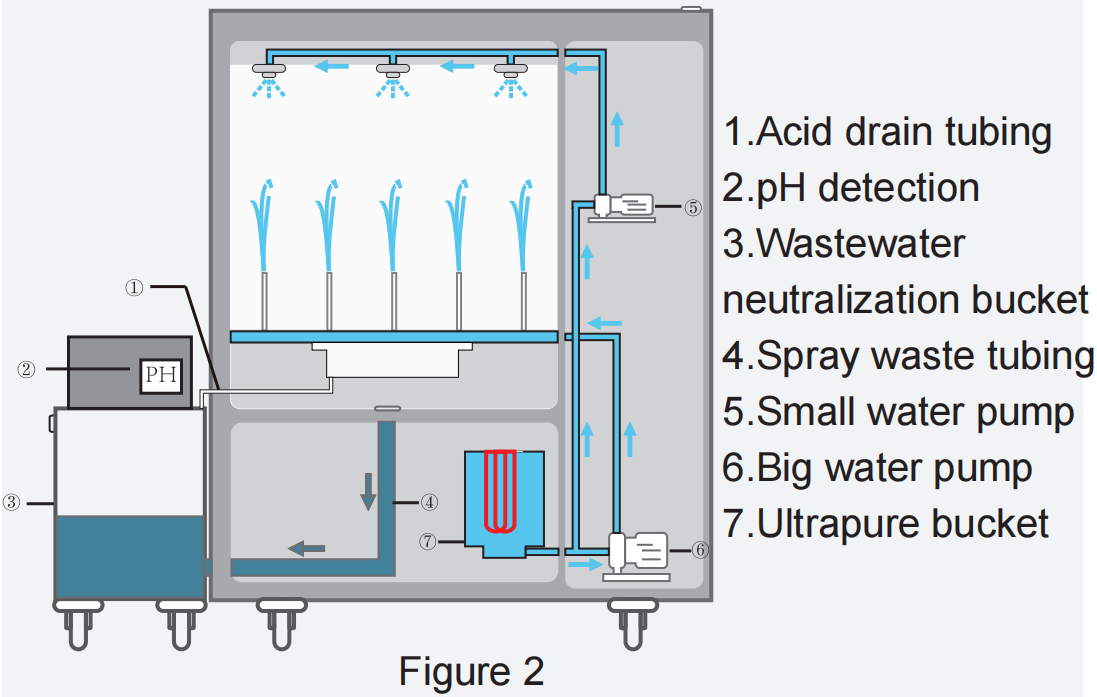

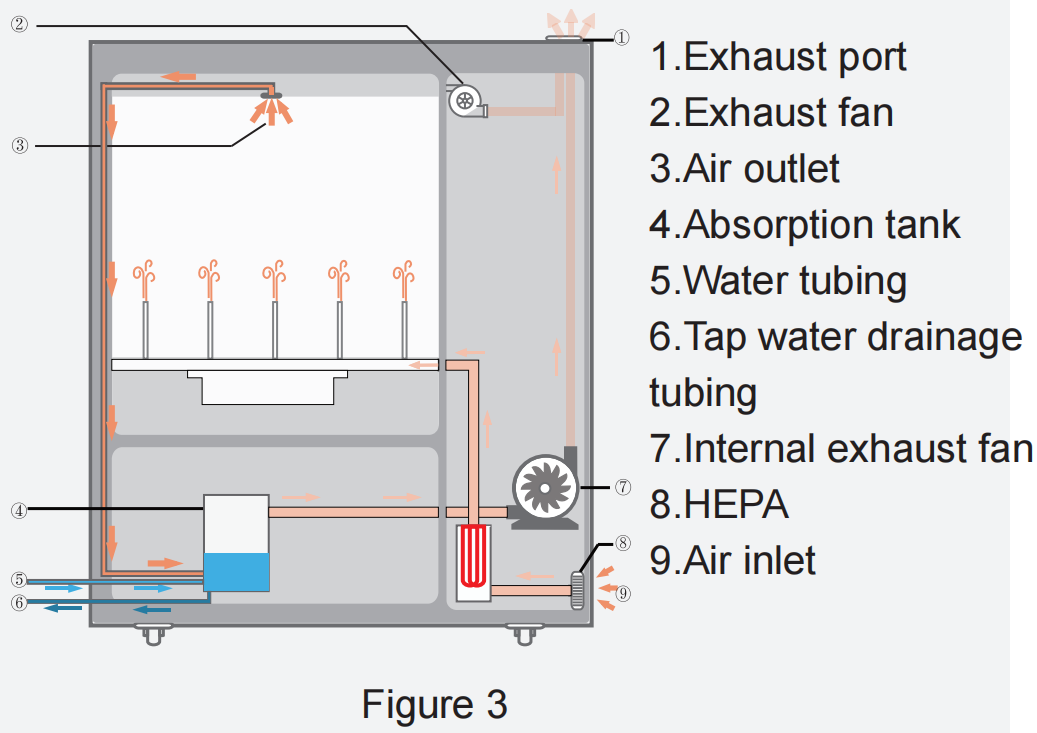

The whole process is automated. Firstly, the beakers, test tubes, crucibles, dissolution tubes, reaction tubes, volumetric flasks and other common laboratory apparatus are cleaned by hot vapour of azotene acid. The entire cleaning process is carried out by heating plates that generate high-purity acid and alkali vapors under repeated convective condensation inside the vessel, with air-cooling of the cleaning machine and additional cooling water. The acid cleaner is air-cooled with additional cooling water. It is then rinsed with ultrapure water and dried with automatic hot air. Compared with the conventional cleaning or acid bubble method, steam cleaning uses less acid and has a shorter cleaning time. Moreover, the entire cleaning process of the acid cleaner is carried out under closed conditions, effectively preventing the acid vapor from contaminating the laboratory.

Workflow of acid steam cleaning system

There is no doubt that this safe acid steam cleaning system will be one of the indispensable laboratory tools of the future. It guarantees the quality of the cleaning and makes the process safer and more reliable. The cleaning process is less consumable and more intelligent, which saves labor and time. The cleaned vessels can reach PPT level or even an undetectable level.

The following is the workflow:

Step 1: Sub-boiling Acid Steam Cleaning: Ultra-pure acid vapor cleans the vessel's inner wall through the vapor conduit. In the process of slowly filling the vessel with acid gas, the gas will condense into liquid and flow down. This process will remove the ionic residues on the vessel's inner wall and effectively reduce the ionic residues.

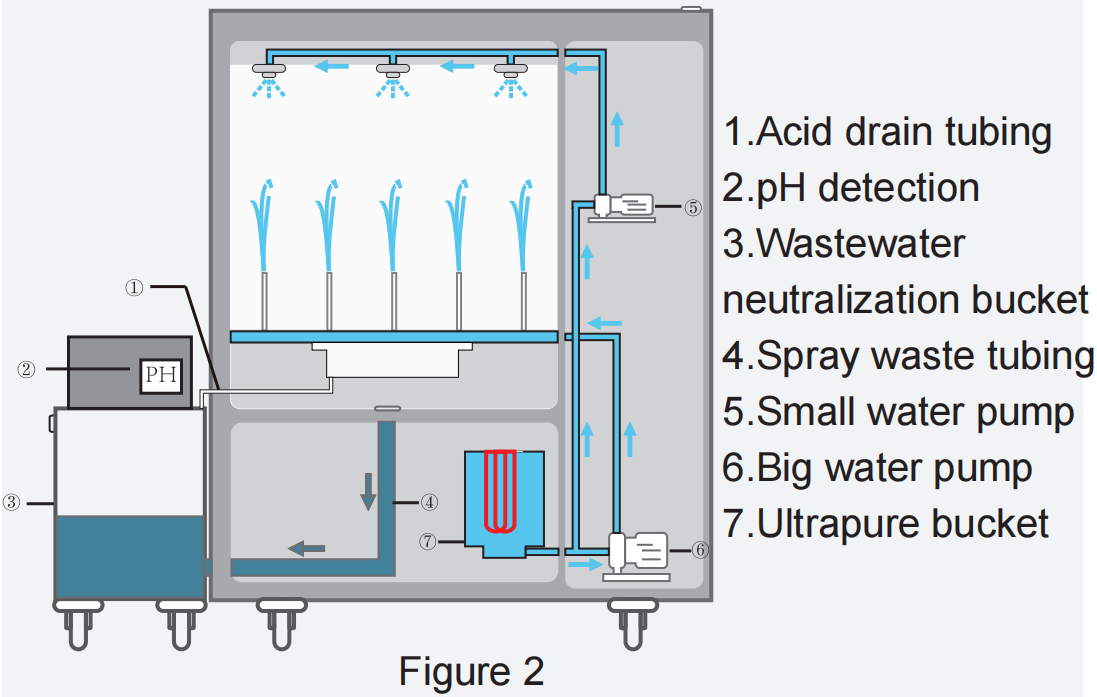

Step2: Ultra-pure water rinsing: "no reflux" ultra-pure water rinsing to ensure that no acid gas and acid liquid remains in the inner cavity (flow rate ≥ 120L/min);

Step3: Hot air drying: Air is blown into the inner vessel after HEPA filter, which can dry the cleaning material quickly (flow rate ≥150m³/h);

Step 4: Neutralisation and discharge: Each time the acid or water is not returned to the original acid or water inside after cleaning, it is directly stored in the waste liquid collector. The machine automatically detects its pH and neutralises the waste liquid to make it neutral before discharge;

Step 5: Automatic acid filling and draining system: Visual acid pool liquid level, with liquid level indication and lack of fluid reminder function. The function of acid liquid emptying and automatic acid filling is convenient for cleaning the instrument and next time use.

Acid Steam Cleaning System

| Model | ASCS-3300 |

| Capacity(L) | 87L |

| Display | 7 inch LCD touch screen |

| Standard Program | 20 |

| Permission Management System | 3 Level |

| Cleaning | Consumption of Acid | 70ml (1ml/min) |

| Cleaning ≥49 Units of 100mL Microwave Digestion Tubes at Once |

| Drying | Drying System | Hot air injection via sprinkler |

| Drying Time Range | 0 to 300mins |

| Drying Temp Range | RT to 100℃ |

| Airflow Rate for Drying | 168m³/h |

| Drying Method | Hot air injection via sprinkler |

| Water inlet pipe | Quantity | 2 |

| Length | 3m (Customizable) |

| Material | PTFE |

| Water Pump | Brand | World-renowned brand |

| Flow Rate | 120L/min |

| Consumption | 0.75kW |

| Structure | Material | External | 304 stainless steel |

| Cleaning Chamber | PTFE |

| Door | Double-door design, for enhanced safety. |

| Caster | Four universal casters at the bottom of the instrument for easy movement |

| Total Consumption | 1.5kW |

| Power Supply | 220/110V, 50/60Hz |

| External Size(W×D×H)(mm) | 1220x600x1100 |

| Shipping Size(W×D×H)(mm) | 1300x710x1340 |

| N.W./G.W. (kg) | 220/249 |

Feature:

Acid cleaner is suitable for all kinds of microwave disintegration tanks, atmospheric pressure disintegration tanks, glassware, quartz material labware, as well as ICP atomization chambers and flame tubes.

The cleaning chamber is made of PFA and PTFE materials with excellent corrosion resistance and no metal fittings to ensure no pollution.

Built-in EP exhaust gas absorption system instantly absorbs a large amount of exhaust gas and can be used without being placed in a ventilated environment.

When the machine is switched on, the exhaust system is automatically switched on, and the cleaning compartment and the whole cavity of the machine are in the state of micro-negative pressure, which provides a strong guarantee for the non-spill of acid gas.

Automatic addition of ultra-pure water, built-in self-priming pump. The pure water tank can remind the lack of liquid and stop automatically when it is full.

Patented three-link dynamic acid tank, fast heating, acid vapor speed is three times that of ordinary heating tanks, acid vapor can be produced in 5 minutes, after acid vaporization, the acid tank automatically tilts to drain the acid, ensuring thorough rinsing of the acid tank with water, and no residual acid after cleaning.

70ml of acid is needed for one cleaning. Acid cleaner greatly reduces the consumption of acid, saving costs.

Patented layered injection cleaning system, with separate acid and water circuits, ensuring no cross-contamination.

The heating module is made of isostatic graphite, resistant to acid and alkali, has high temperature, high conductivity and high heat preservation performance and is treated with Teflon anticorrosion coating.

Applying an automatic quantitative acid-adding and discharging system changes the fatal defects of traditional funnel-adding acid and valve-discharging acid, ensures the safety of laboratory personnel, and makes acid steam cleaning more intelligent.

Adopting PID temperature control technology, accurate temperature control, high precision, fast heating, with temperature calibration function, with temperature overshooting protection function.

Applications:

The acid steam cleaning system integrates cleaning, rinsing, and drying with pure water, and it is widely used in labware cleaning. It can safely clean all kinds of glass, quartz, PFA, PTFE, TFM and ICP/MS fittings in trace analysis to remove inorganic element residues, effectively reduce ionic background and meet the needs of trace detection.

In addition, acid cleaners have been widely used in food, agricultural products, grain and oil, the environment, and other fields to help experimenters solve the thorny problem of metal ion cleaning.

Difference Between Acid Cleaner and Glassware Washer

Glassware washer is mainly composed of stainless steel pump, high-pressure nozzle, electrical box, etc. It is suitable for cleaning glass bottles, beakers, etc. It must be used with the cleaning rack and mainly through the high-pressure water jet repeatedly rinsed to remove a variety of contaminants on the surface of glassware, such as chemicals, residues, oils and biological substances.

In inorganic experiments, the difference between an acid and a glassware washer is obvious.

Ordinary glassware washing machines are made of stainless steel, so in the cleaning process, there will inevitably be part of the precipitation or dissolution that can not meet the inorganic experiments on deionizing the vessels of ultra-high requirements.

Therefore, the acid cleaner can only meet this requirement because the inner cavity of the acid cleaner is made of PTFE, which can meet the high requirements of inorganic experiments.

Application of Acid Cleaner

The acid cleaner system integrating cleaning, pure water rinsing and drying is widely used in laboratory experimental vessels cleaning, which can safely clean all kinds of glass, quartz, PFA, PTFE, TFM, etc. vessels and ICP/MS fittings in microanalysis to remove the residues of inorganic elements, effectively reduce the ionic background, and meet the needs of trace detection.

In addition, this acid cleaner has been widely used in food, agricultural products, grain and oil, the environment and other fields to help experimenters solve the thorny problem of metal ion cleaning.

How to Maintain Acid Cleaner

For a pickling machine to work efficiently for a long time, it is vital that it is properly maintained on a routine basis. Several inspection and maintenance guidelines are listed next to ensure that it operates properly and provides reliable cleaning results.

Flow meters, PH meters, temperature sensors, fans, etc., are regularly checked quarterly, and the dust on the fans is regularly cleaned.

Take regular care to observe whether there is any abnormal sound in each part, and check whether there is any screw loosening.

Before each use, check whether there is enough reagent liquid in the alkali and acid bottles. If not, add it to the corresponding position in time.

Every six months, we need to check the color change of the acid gas filtration adsorption column. If the color is light, we need to replace the filtration adsorption column.

Conclusion

Acid cleaners offer a safer and more convenient way to clean more laboratories, especially in heavily contaminated or stained applications. While traditional acid cleaning chemicals can be a safety hazard to handle and potentially damaging to utensils, Acid cleaner offers superior cleaning performance while ensuring maximum safety.

We understand the importance of sustainability, which is why our acid cleaner is designed to be environmentally friendly. It optimizes the use of water and chemicals, reducing waste and environmental impact without compromising on cleaning results.

English

English