Ethylene oxide sterilization stands out as the most efficient gas sterilization method currently available. It offers a range of advantages, including broad-spectrum sterilization capabilities, strong penetration into various materials, no damage to items, minimal environmental impact, dependable chemical and biological testing methods, and convenient storage of sterilized items. As an indispensable low-temperature sterilization technology, it plays a crucial role in hospitals, ensuring the safe and effective sterilization of a wide array of medical equipment and devices.

Ethylene Oxide Sterilizer Applications:

Materials that can be sterilized include hysteroscopes, laparoscopes, laryngoscopes, probes, rigid endoscopes, flexible endoscopes, ophthalmic lenses, fiber optic intracranial sensors, cryotherapy probes, prostatectomy devices, esophageal dilators, electrocautery equipment, defibrillation motors, laser heads, metals, glass, silicone, rubber, traditional Chinese medicine, Western medicine, human implants, etc.

Ethylene Oxide Sterilizer Specifications:

| Model | ST-EO80 | ST-EO120 | ST-EO220 | ST-EO330 | ST-EO120I | ST-EO220I |

| Capacity | 67 L | 103 L | 196 L | 294L | 126L | 192L |

| Sterilizing Temp. | 36-55℃ |

| Product Form | Manual door vertical |

| Heating method | Electric heating |

| Display | 5’’ LCD Touch Screen | 7’’ LCD Touch Screen |

| Controller | PLC |

| Sterilizing Time | Adjustable 0-99 hour |

| Sterilizer Pressure | -60kpa |

| Sterilization Method | Low temperature, 100% Pure EO gas sterilization |

| Safety Protection | Temperature and Pressure protection |

| Tray | 2 stainless net steel |

| Printer | Built-in Thermal mini-printer |

| USB Port | Yes |

| Internal Material | SS304 Stainless Steel | 5052 Aluminium, has better thermal conductivity than stainless steel |

| External Material | Carbon steel |

| Vacuum system | High-performance, low-noise, oil-free vacuum pump |

| Humidity System | Use saturated steam to humidify the sterilization chamber, and the air humidity is more uniform |

| Timing System | EO gas diffusion time and residual EO aeration timing settable |

| Pre-set | Standard Sterilization Mode and Residual Washing |

| Power Supply | 220V, 50Hz |

| Consumption | 2.6KW | 3.0KW | 3.3KW | 3.6KW | 3.0KW | 3.6KW |

| Internal Size (mm) | 585x275x422 | 585x375x472 | 705x505x552 | 760x545x712 | 700x450x400 | 820x510x460 |

| External Size (mm) | 795x615x1140 | 795x615x1140 | 968x800x1240 | 968x800x1400 | 976x790x1715 | 976x790x1715 |

| Net Weight | 124kg | 147kg | 207kg | 227kg | 227kg | 247kg |

| Package Size (mm) | 970x770x1310 | 940x750x1310 | 1120x920x1400 | 1020x930x1530 | 1130x920x186 0 | 1130x920x1860 |

| Gross Weight | 150kg | 177kg | 237kg | 277kg | 274kg | 297kg |

Ethylene Oxide Sterilizer Features:

The fully automatic control system ensures a seamless operation with a single click, managing the entire process from start to finish automatically.

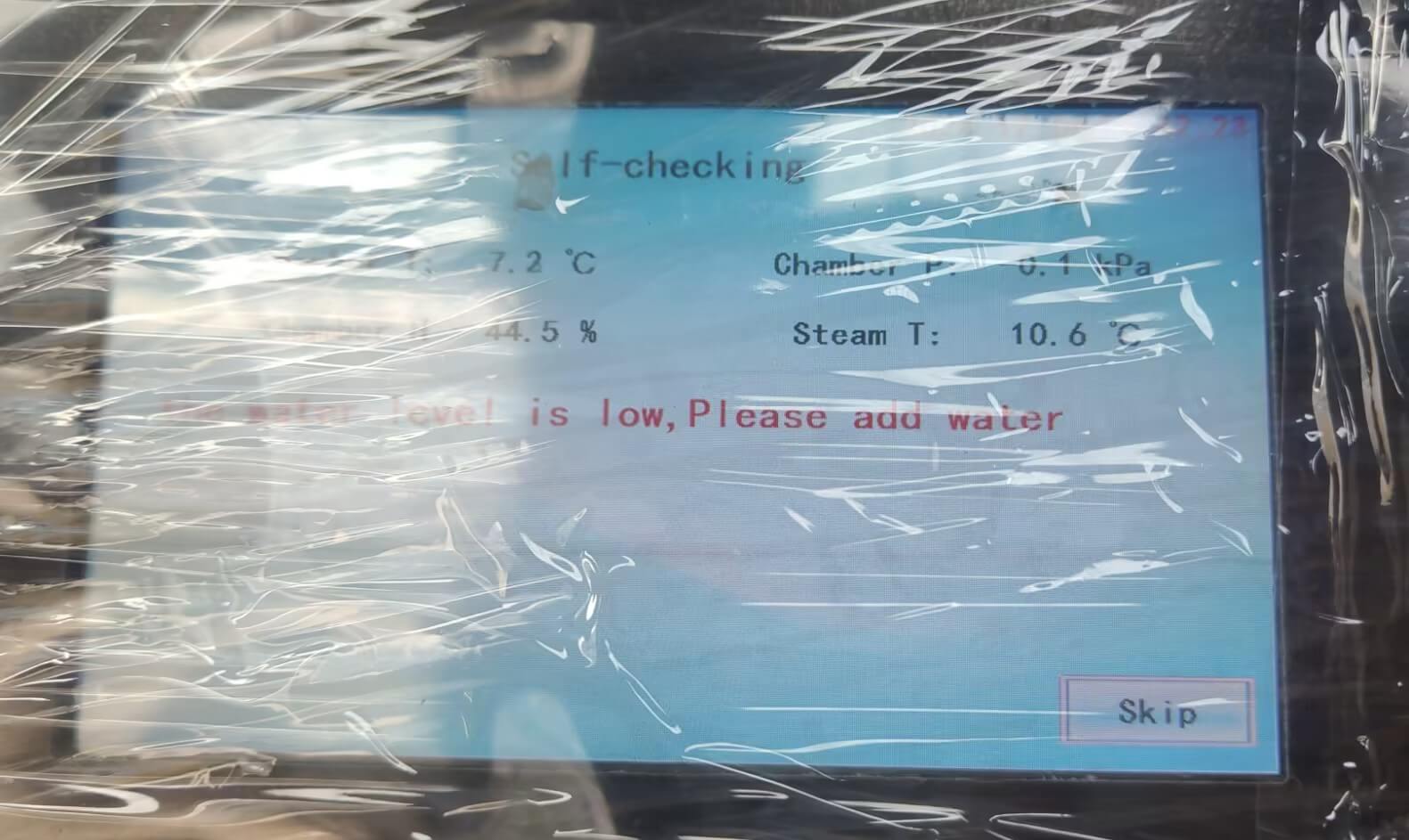

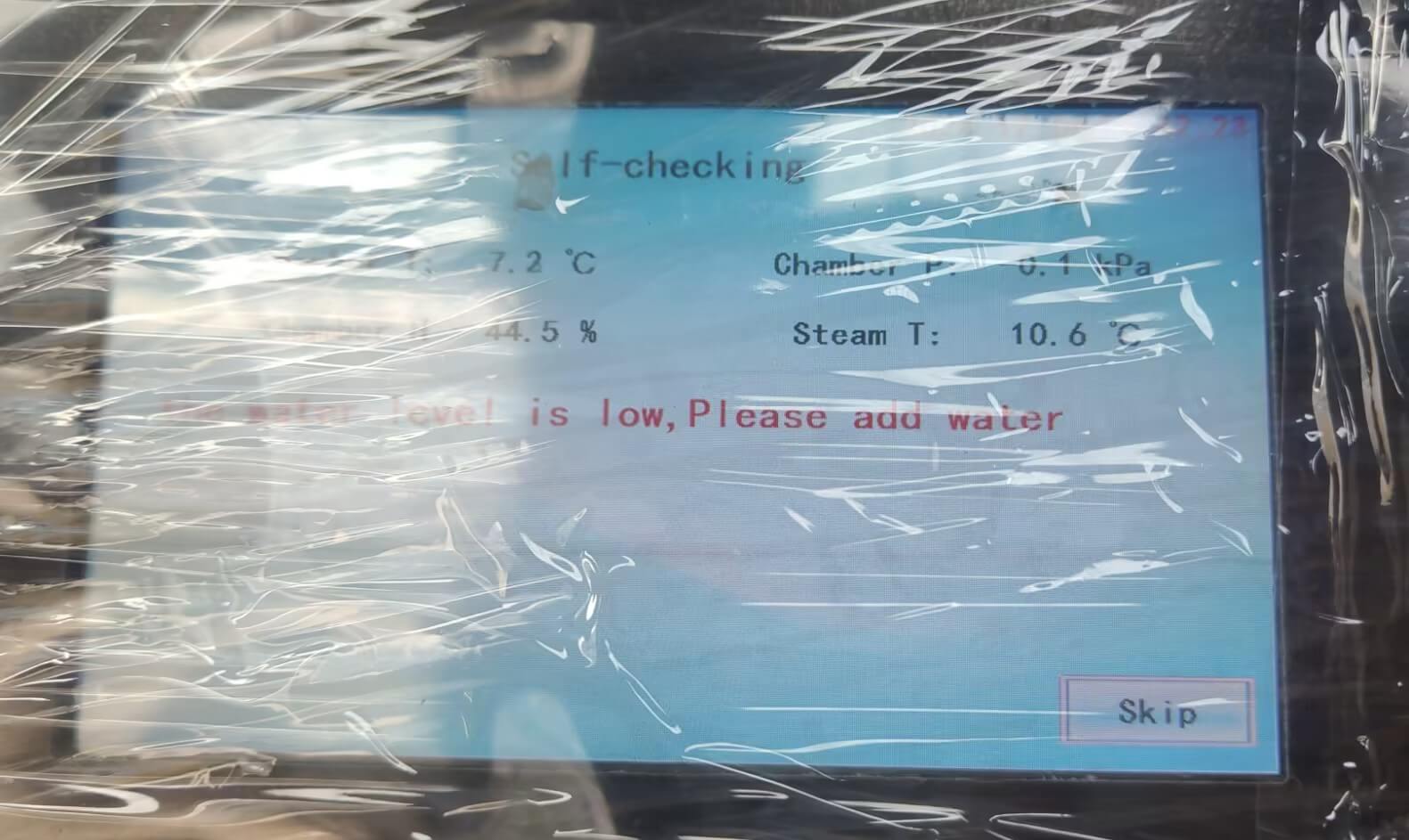

The display screen provides real-time information, including temperature, humidity, pressure, disinfection time, residual gas treatment time, and frequency for convenient monitoring.

Ethylene oxide sterilizer is equipped with built-in sensors, the system autonomously monitors and adjusts temperature, humidity, and pressure levels within the chamber.

The sealing door, crafted from 5052 aluminum material, boasts a robust pressure resistance of 200Kpa, guaranteeing a secure seal that prevents any leakage of ethylene oxide gas.

Residual gas treatment device filter for particle diameter ≥ 0.2 μm The filtration rate of m is not less than 99.5%.

Details of EO sterilizer (ST-EO220I):

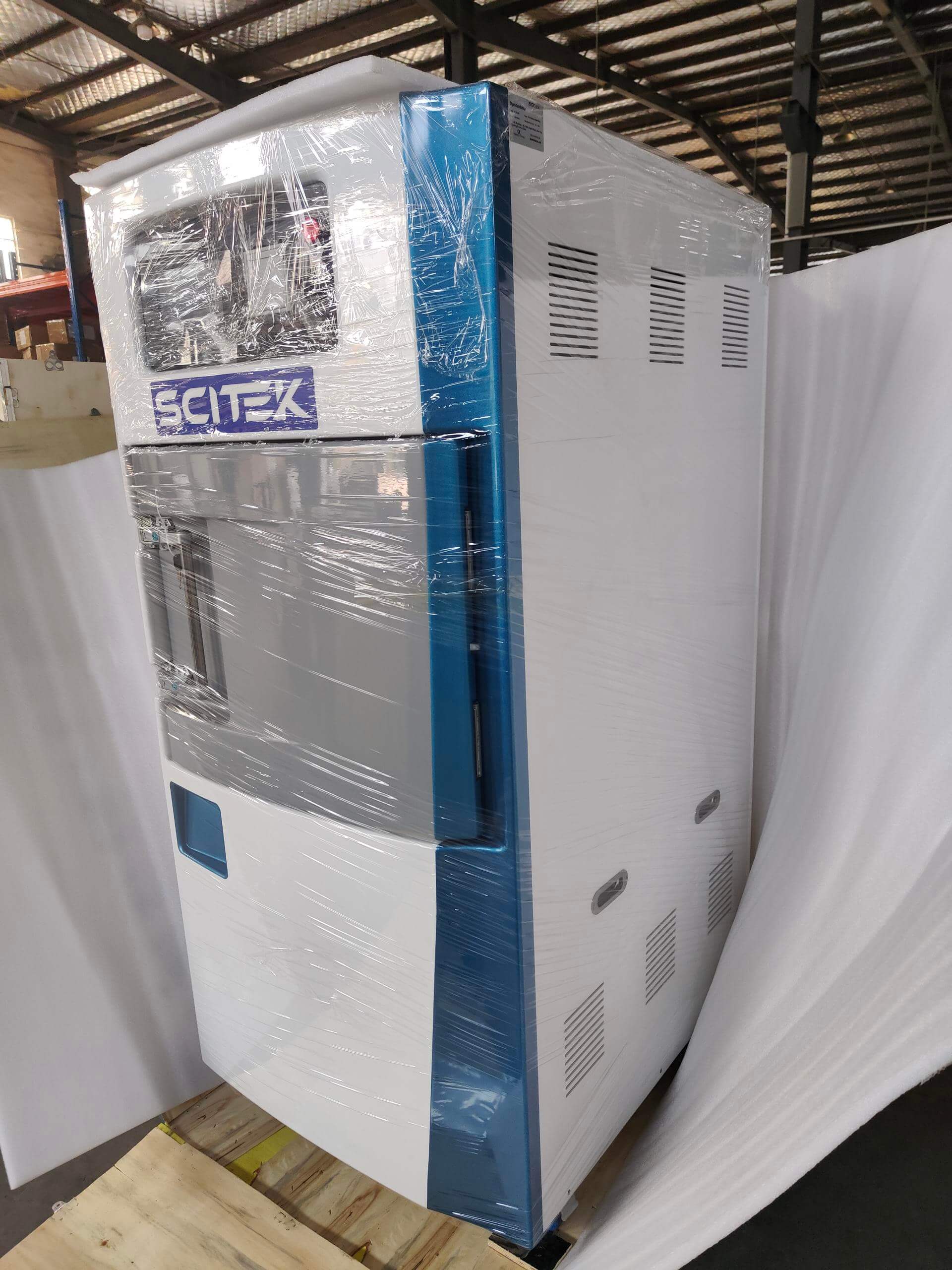

Each ethylene oxide sterilization equipment is individually wrapped in protective foam to ensure that it is not damaged during shipping. Clear labeling makes the device model and details readily apparent.

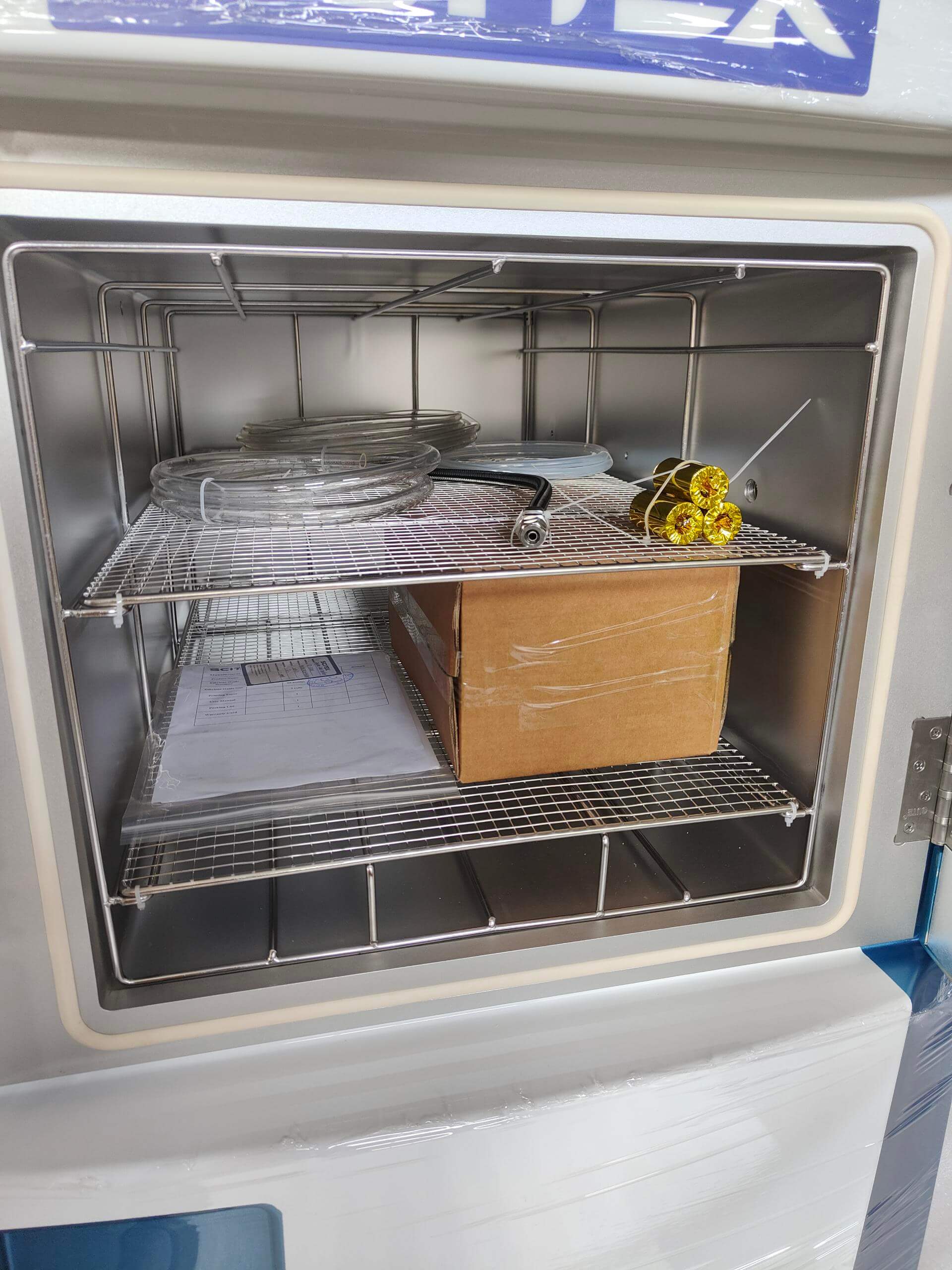

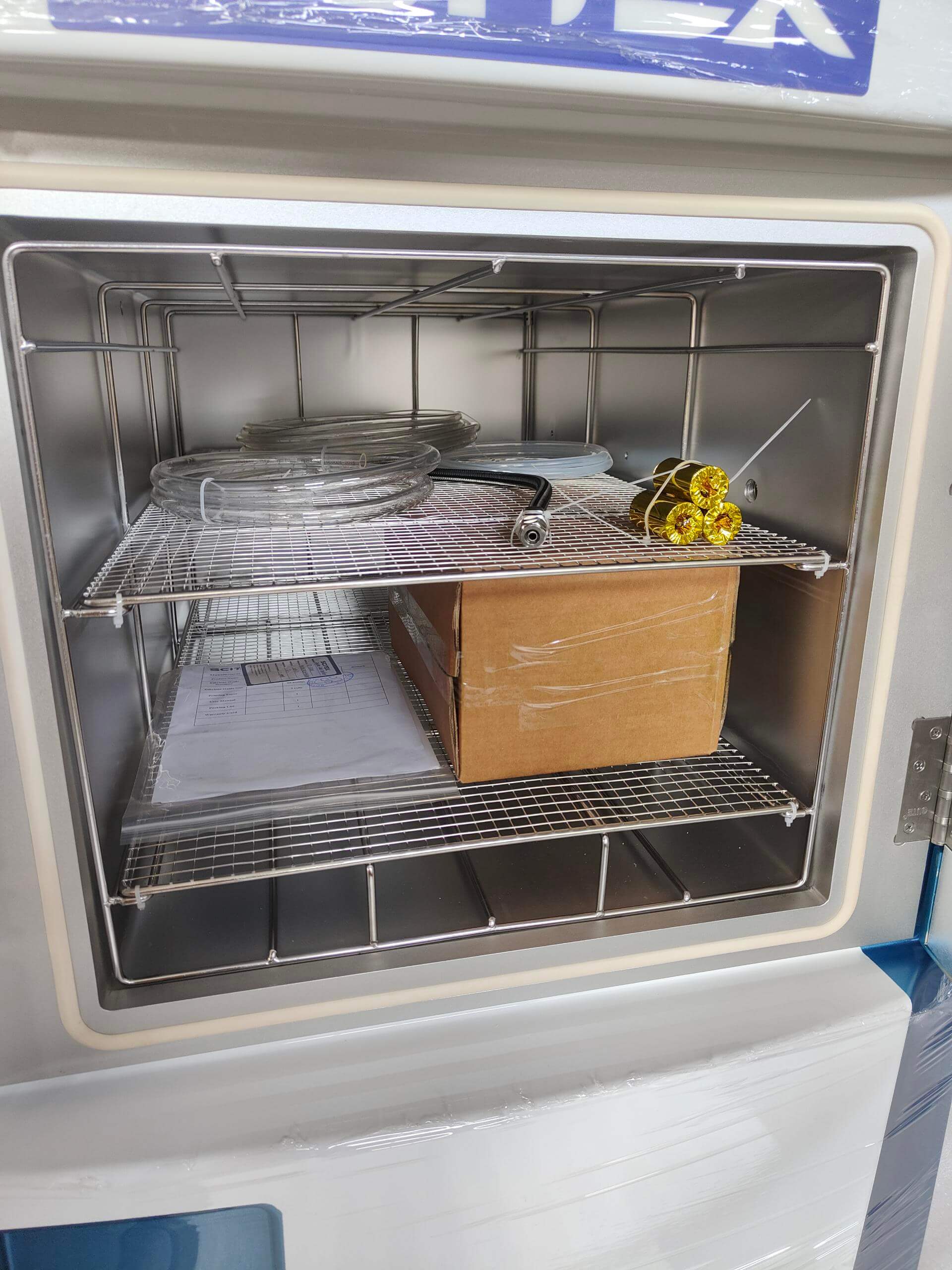

The metal racks and temperature control system inside the Ethylene Oxide Sterilizer take into account the safety and efficiency of the operation and ensure a uniform and efficient gas flow during the sterilization process.

Ethylene oxide sterilization equipment has a good ventilation and heat dissipation system at the back to ensure stable operation during long time use.

EO sterilizers are equipped with a modern display interface, which clearly shows the operating status and parameters, making it easy for users to set and monitor.

What is ethylene oxide processing?

Eco chamber ethylene oxide sterilization consists of four main variables:

Gas concentration

Humidity

Temperature

Time

EO is an alkylating agent that disrupts the cellular metabolism and reproductive processes of microorganisms.EO penetrates through breathable packaging and comes into contact with all accessible surfaces of the product to achieve the desired sterility assurance level (SAL).

What is Ethylene Oxide used for?

EO is suitable for sterilizing a wide range of materials that are not compatible with other sterilization methods. Products typically treated with Ethylene Oxide include:

Assemblies of complex equipment

Catheters

Customized procedure packages

With integrated electronics

Multi-lumen tubing products

Stents

Wound Care Dressings

English

English